PCB Assembly Manufacturing Services

Our team offers a suite of complete PCB assembly optionsPCB Assembly Supplier

We design the perfect custom PCBA solution for our clients

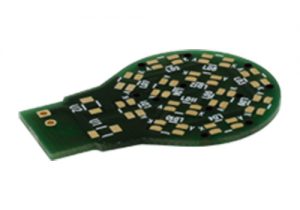

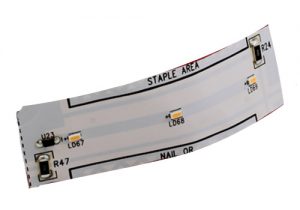

A printed circuit board (PCB) is a board used to hold a chip or other electronic components. To accommodate various design needs, a PCB can be a single layer or consist of multiple layers. PCBs can also be single-sided or double-sided in design. Several PCBs can be linked in a single device, using either flexible or rigid connectors.

Our reliable PCB assembly offerings do more than optimize indication and light output — they do it in the most efficient and effective ways possible. We provide solutions that solve design challenges while minimizing production and assembly costs.

We can design and manufacture rigid and flexible PCBs up to four layers thick, ensuring conformance with UL, cUL, CE, RoHS, REACH and other regulatory requirements.

PCBA Design Options

PCBs can be either flexible or rigid in design

Rigid

Flexible

Core Capabilities

A complete North American manufacturer

Manufacturing Expertise

To develop innovative solutions that add significant value to end products, we offer our customers the appropriate expertise:

• Expert engineers and designers

• High-quality and reliable HMI Components

• Lean production knowledge

• Conformance with CE, UL, cUL, RoHS, WEEE, and other standards

• Environmental Management System

Production and Supply Chain

Our North American production sites and distribution warehouses in North America, Europe, and Asia ensure the planning and production of products to ISO 9001.

• PCB design and manufacturing

• SMT placement, assembly and inspection

• Cable crimping, cutting, harnessing and final assembly

• Consistent processes at all locations, with integrated supply chain quality measures

Mechanical and Electrical Design

VCC works closely with you to prepare detailed drawings, parts lists, and circuit schematics. VCC helps you cut development times using rapid prototyping techniques for plastic components and PCBs.

• 3D CAD (Solidworks, AutoCAD)

• PCB design and simulation software

• Gerber file creation for PCB manufacturing

• Rapid prototyping (3D Printing

Quality Assurance and Testing

Our products and systems undergo testing to assure reliability, repeatability and a long service life.

• Laboratory tests with appropriate software

• Environmental test chambers (temperature and humidity)

• Compliance to different levels of protection

• Testing the durability of individual components

• Optical simulation and analyses

• Final inspection on all products

Advanced Equipment Drives Better Outcomes

We combine the latest manual and automated techniques to ensure you get exactly what you need. But our advanced equipment and processes aren’t the only reasons to work with us.

■ Solder Paste Application

■ Automated Pick and Place Machines

■ Automatic Dispensing Carts

■ 8-Zone SMT Solder Reflow Ovens

■ Automatic Wave and Soldering Machine

■ Advanced PCB and Stencil Cleaning Machine

■ Advanced ESD Control System

■ Conformal Coating Equipment

■ Visual Scanning Microscopes

■ Visual Camera for Quality Check

PCBA FAQs

PCBA most frequently asked questions

1. What’s included in the total cost of a PCB order?

2. Which PCB types does VCC offer?

3. Which PCB services does VCC offer?

- Custom design services to optimize output and indication

- Rapid prototyping made even faster and cost-effective with our in-house 3D printer

- Sample runs so you can easily test concepts and tweak designs

- Mass production to efficiently accommodate large quantities

If you have additional questions, or are ready to discuss your next project, we’re here to help.

Contact us today for your PCB, PCA and PCBA needs.

PCB Assembly Partner

VCC can customize your components with full PCBA design and production capabilities — right here in North America