Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

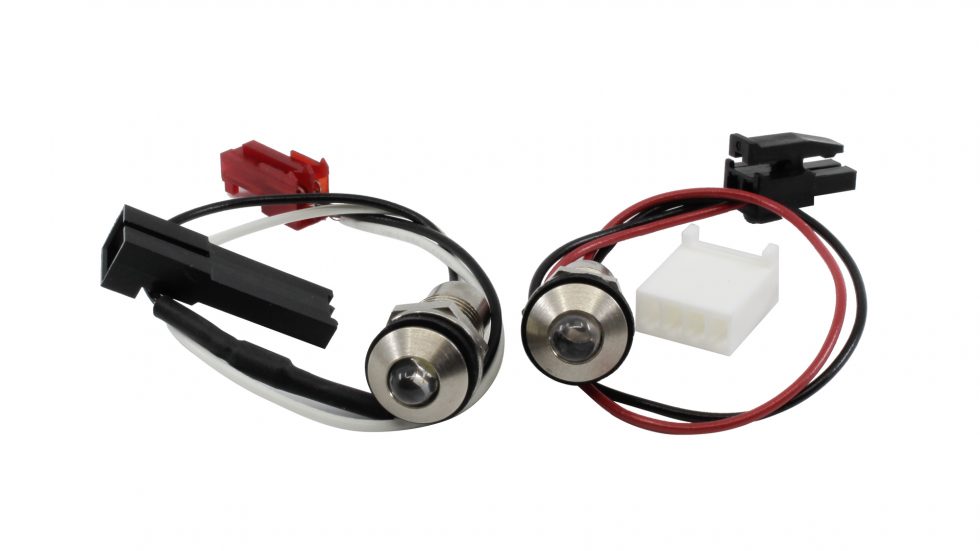

Cable Crimping

When using connectors instead of soldering electronic components to the device, the cables must be crimped where the bare cable is terminated inside the connector.

This process can save a step in production when it’s handled by the manufacturer of the indicator. Learn more here. -

Cable Cutting

Before a connector can be used, the bare wire just be sized appropriately and stripped at the connection point.

OEMs like VCC offer cable cutting and crimping as value-add services that increase production and assembly.

-

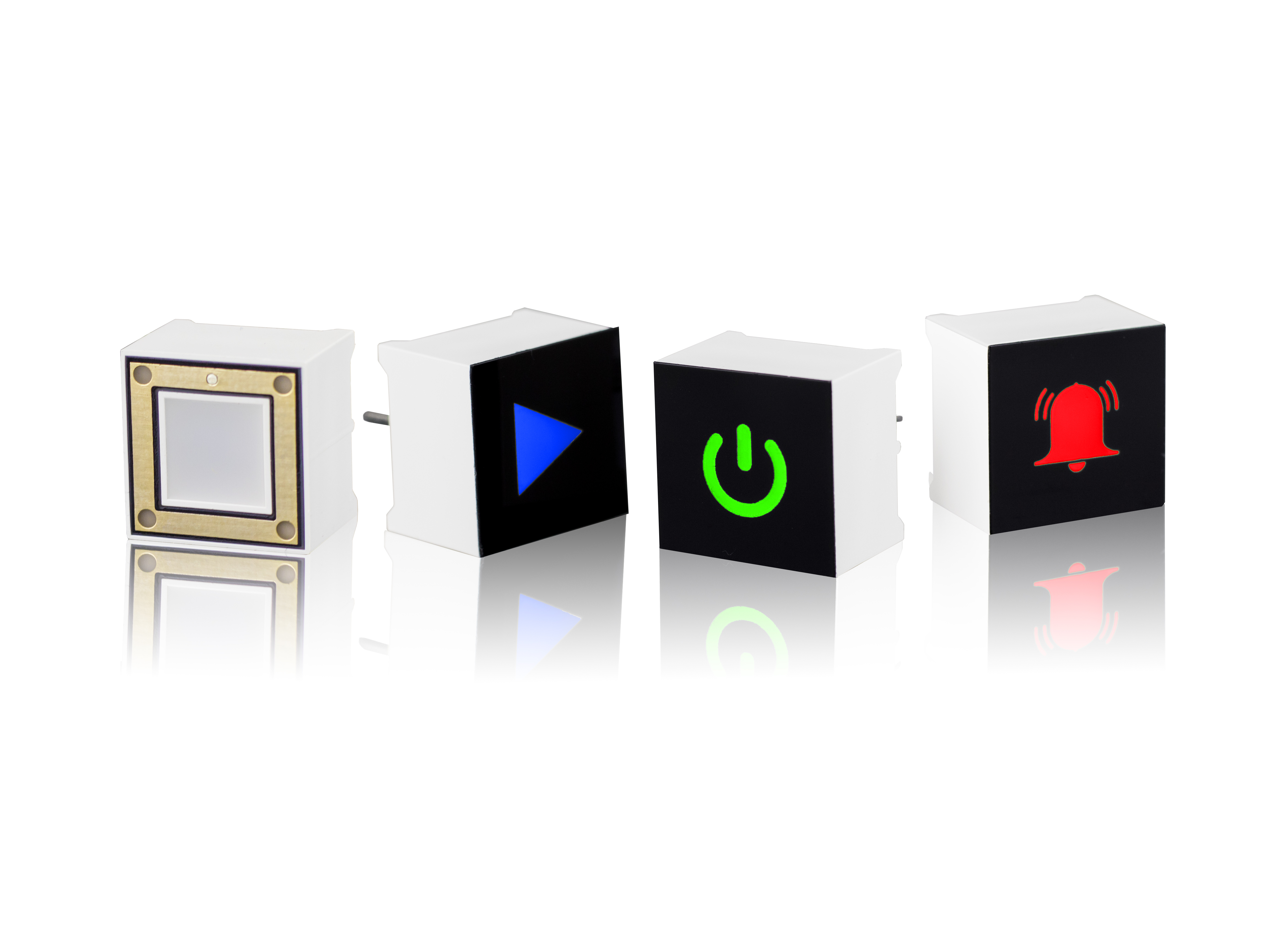

Capacitive touch

Capacitive touch uses sensing and display technology to provide an intuitive user experience. By combining icons and colors to communicate status, reaction times are increased.

These cap touch sensors can be solid colors or include an icon overlay. For example, VCC’s CSM Series uses surface-mount (SMD) technology to mount LED sensor displays to the HMI.

-

CE Mark

A product labeled with the CE mark indicates it meets all safety, health and environmental standards and laws required for sale within Europe.

-

Chassis

Made of stainless steel, plastic, aluminum, or polycarbonate, a chassis is an enclosure that helps protect the sensitive, yet critical electronic elements of a device.

Working conditions and exposure to moisture and dust should be determining factors when selecting a chassis material.

-

Color – Light Pipe Color

Light pipes are usually clear or white, yet the color used can help determine the visual language of a device. Common color options are red, yellow, blue, and orange.

Some colors help carry more of the light from Point A to Point B. Others help focus the light, so it doesn’t bleed into a different color on the control panel and cause confusion.

-

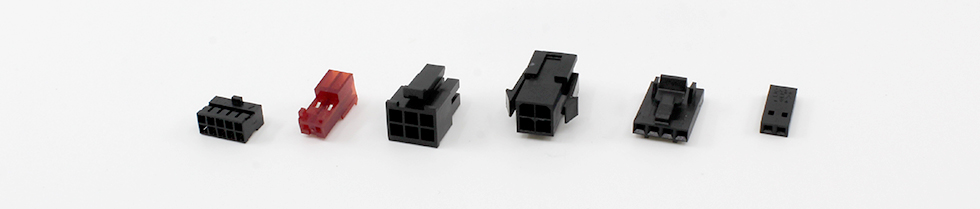

Connectors

Panel mount indicators can be connected by soldering the components to a device, or by using modular wire-to-wire connectors to establish a secure connection.

Connectors help speed up production and assembly by making the process more efficient. Several types of connectors can be added to PMIs, including 2-position, micro-fit, and more.

-

Control Panel

A control panel is the interface on a device where the operator can monitor status, and in some cases, use buttons or knobs to operate the machine.

There are many design and development techniques that can improve the communication between operator and machine. Explore our Status Light Guide to learn more.

-

Crimp Housing Connector

Crimp housing connectors are used to create solderless connections between terminated wires. The stripped wire is inserted into the connector, then “crimped” to provide a mechanically sound bond. Learn more about VCC’s connector solutions here.

-

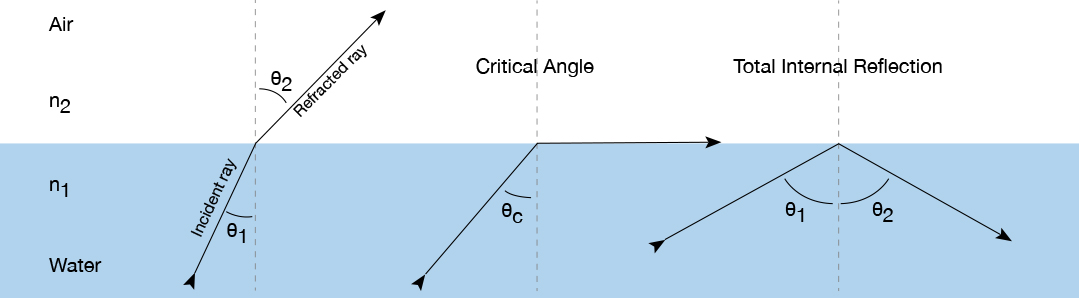

Critical Angle

The critical angle is the angle of incidence or limiting angle that creates refraction. Depending on the medium used for the light pipe, the critical angle will vary.

Exact calculations are required for the best outcomes, utilizing total internal reflection (TIR) to help the maximum amount of light reach the desired exit point.

-

CSA Mark

Similar to the CE mark in Europe, the CSA mark on a product indicates it has met the safety and testing requirements of the Canadian Standard Association Group.

This includes standards written or administered by the American National Standards Institute (ANSI), Underwriter Laboratories (UL), CSA Group (CSA), and other organizations.

-

Custom Light Pipe

While VCC offers thousands of standard light pipes, sometimes a customized solution is the ideal one for the footprint, operating conditions, and optical properties.

Whether it’s a light engine or a light pipe, customizing can help reduce costs in the long run.

-

Custom PMI

A custom PMI is one that is either designed from the ground up using customer specifications or requirements, or the modification of an existing panel mount indicator.

VCC can create a new PMI design or customize thousands of standard products by changing the color, wattage, length of leads, lens options, and IP rating. Build your own PMI here.