Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

Acrylic Light Pipes

Typically made of PMMA (polymethylmethacrylate), acrylic light pipes are optical-grade and the preferred solution for a range of status indication applications.

They provide superior light transmission compared to other light pipe materials. They’re also more cost-effective, and operate in temperatures from 80-110°C.

-

Bezel

A bezel is a ring that encases an LED in order to hold the lens in place or connect the lamp to the housing. It can be made of plastic, stainless, steel, nickel, or other material.

Made of plastic, stainless, steel, nickel, or other types, this element provides a secure, mechanical fit that can provide protection from moisture and dust.

-

Bi-Color

A bi-color LED is one that can change from one color to another within the same LED/status indicator. Red/green or red/yellow are common bi-color combinations.

VCC can also customize a color combination to accommodate any visual language or design requirement.

-

Bi-Pin

A bi-pin is a type of lamp fitting that uses two pins to connect the bulb to the device. This fitting is commonly used in LED, incandescent, halogen, neon and fluorescent lamps.

-

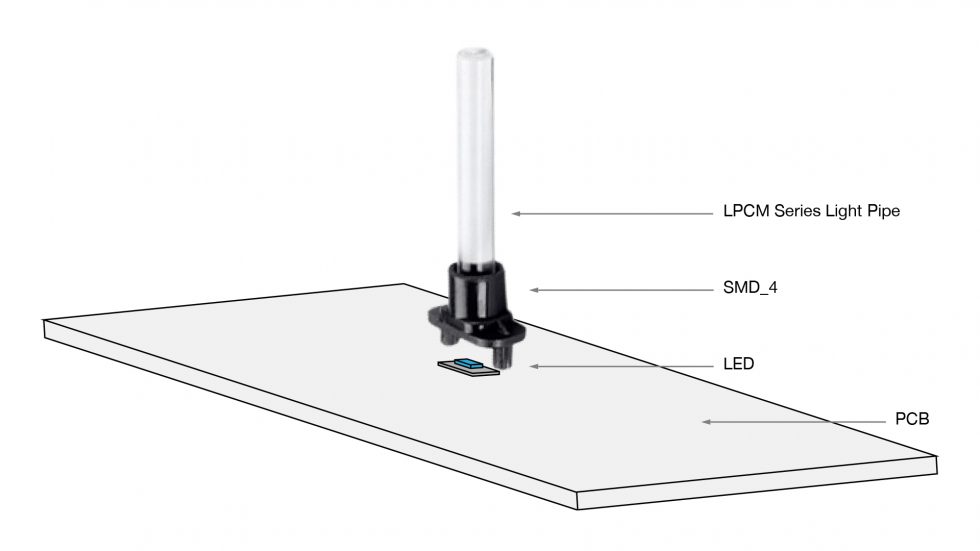

Board-Mount Light Pipes

Board mount light pipes are affixed to the PCB of the device, instead attaching to the control panel or HMI. In some instances, they may also attach to the HMI for added security.

In addition to providing design flexibility, board-mount light pipes can also protect components from electrostatic discharge (ESD).

-

Brightness

The brightness of any type of LED, indicator, or lamp is measured in lumens. The higher the lumens, the brighter the light.

Unlike other lighting technologies, an LED can achieve full brightness in milliseconds.

-

Bulk Scatter Material

Bulk scatter is a technique used to diffuse light throughout a light pipe by applying bulk scatter materials, such as treated powders, to the light pipe.

Bulk scatter materials can help improve uniformity and reduce hotspots.

-

Cable Crimping

When using connectors instead of soldering electronic components to the device, the cables must be crimped where the bare cable is terminated inside the connector.

This process can save a step in production when it’s handled by the manufacturer of the indicator. Learn more here. -

Cable Cutting

Before a connector can be used, the bare wire just be sized appropriately and stripped at the connection point.

OEMs like VCC offer cable cutting and crimping as value-add services that increase production and assembly.

-

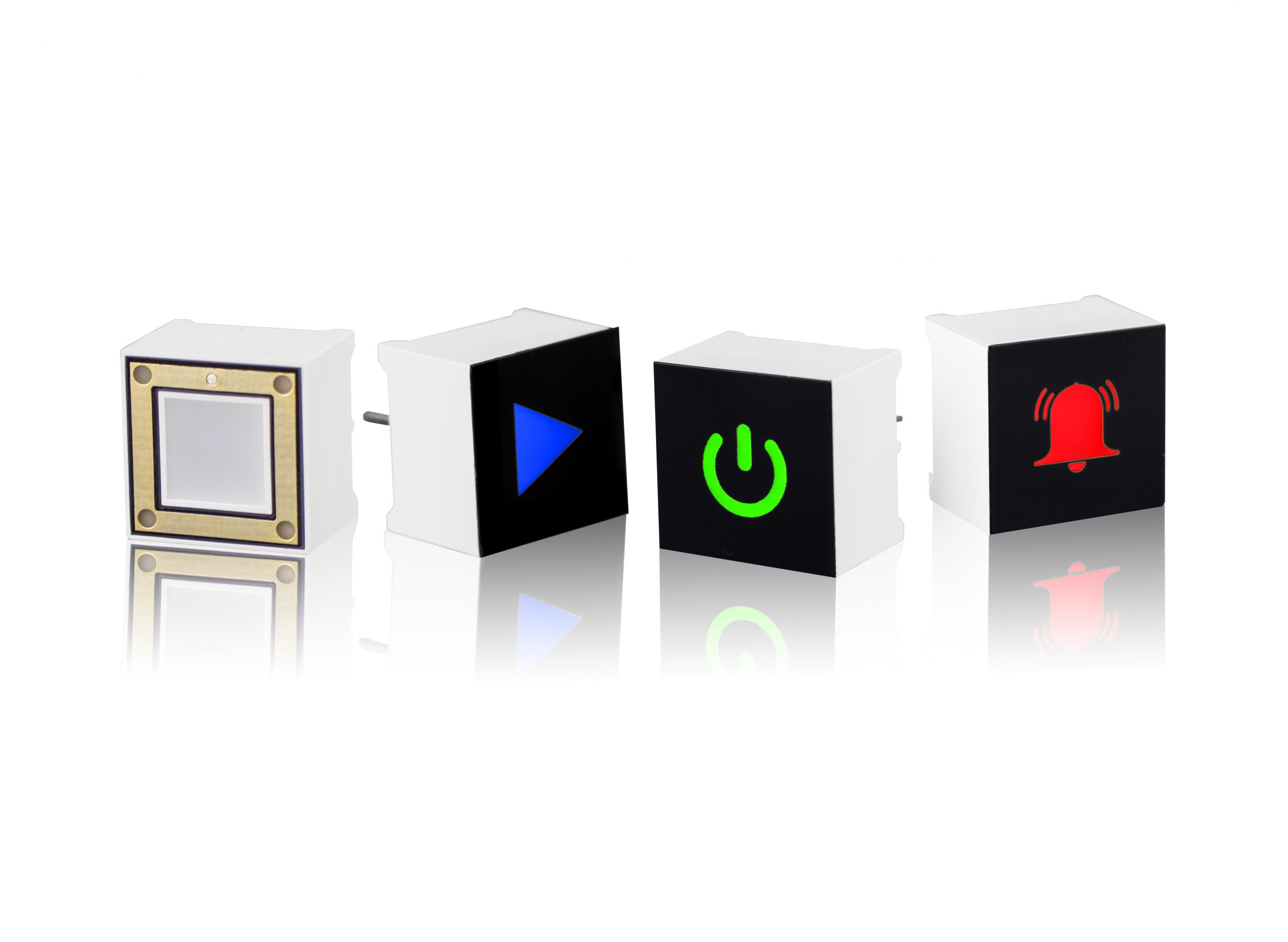

Capacitive touch

Capacitive touch uses sensing and display technology to provide an intuitive user experience. By combining icons and colors to communicate status, reaction times are increased.

These cap touch sensors can be solid colors or include an icon overlay. For example, VCC’s CSM Series uses surface-mount (SMD) technology to mount LED sensor displays to the HMI.

-

CE Mark

A product labeled with the CE mark indicates it meets all safety, health and environmental standards and laws required for sale within Europe.

-

Chassis

Made of stainless steel, plastic, aluminum, or polycarbonate, a chassis is an enclosure that helps protect the sensitive, yet critical electronic elements of a device.

Working conditions and exposure to moisture and dust should be determining factors when selecting a chassis material.