Sannah Vinding | September 2, 2020

Light pipes are an essential component in modern lighting solutions, providing efficient illumination for various applications. Light pipes offer several functionalities, including the efficient transport of various types of light, such as UV, infrared, and visual light, from an LED source to a user interface. They are known for their design flexibility, cost-effectiveness, and reliability, making them a popular choice in the industry. By understanding the materials and configurations that enhance their performance, designers can effectively utilize light pipes to achieve optimal lighting results.

Introduction to Light Pipes

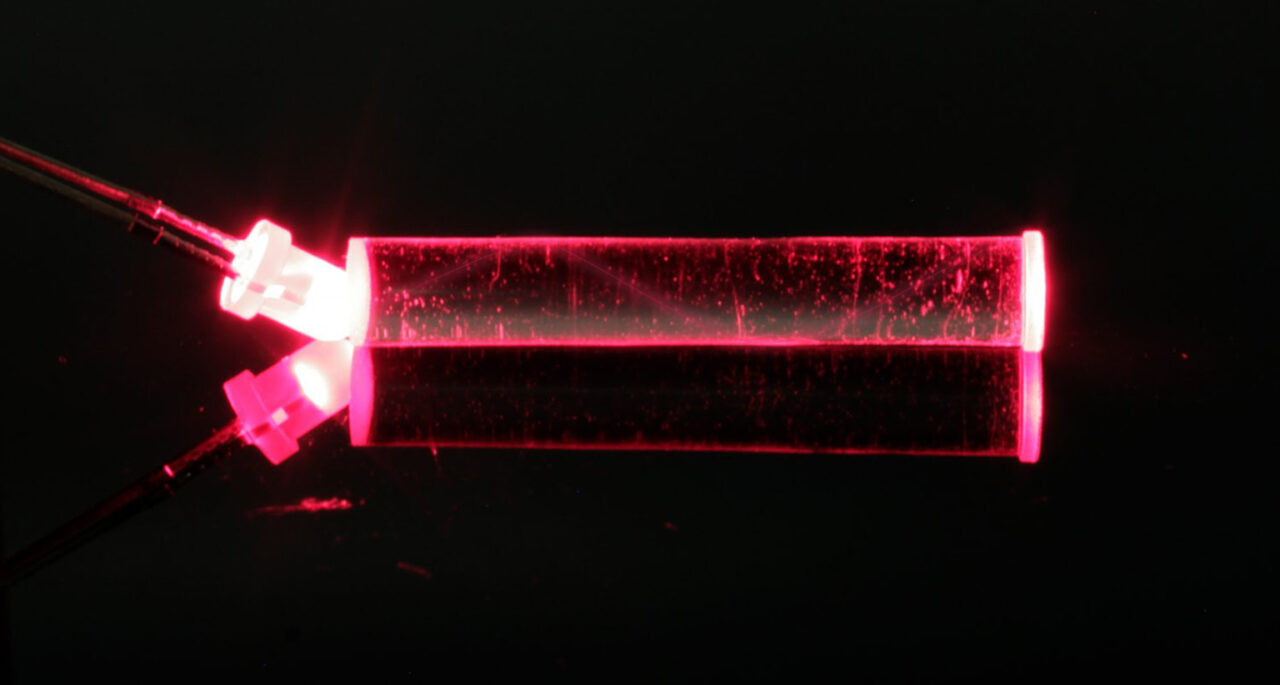

Light pipes are tubular structures designed to transmit or distribute light from a light source, providing efficient illumination for various applications. Commonly found in industrial machines and domestic appliances, light pipes are essential for devices that use LEDs as control indicators. These light guides are typically made from optical-sensitive plastics such as acrylic and polycarbonate, which ensure high efficiency and minimal loss of light concentration. LED light pipes come in two main types: rigid and flexible. Both variants are adept at directing light waves with little to no loss in intensity, making them ideal for illuminating user interfaces in hardware products. By offering reliable and consistent illumination, light pipes play a crucial role in enhancing the functionality and user experience of many devices.

Light Pipes & TIR: The Combo for Optimum Performance

As you’re likely painfully aware, light pipes seem simple, but in all actuality, they are pretty complex. So many decisions that can impact how well (or not so well) a light pipe performs — from the brightness and viewing angle of the LED to the material and shape of the light pipe itself. One critical design consideration is the minimum allowable distance between the LED source and the light pipe to ensure optimal light transmission efficiency and prevent heat damage.

Why is it so difficult to shine light through a tube and have it exit exactly where you want it?

To get the light to behave precisely how you need it to, we first have to dive into some fun phenomena in physics that complicate the tasks at hand. Designers must also account for the heat produced by LEDs, as excessive heat can negatively affect the performance and longevity of the light pipes.

Everything You Need to Know About Light Pipes

Challenge #1 – Understanding How Different Surfaces Impacts Your Illumination

Ever notice how lights shine differently through different materials?

When designing a light pipe, it will become obvious that a ray of light shifts in direction when shone from one surface to another, like through water to air. This phenomenon called refraction is the shift in direction of a wave of light. Light pipes are designed to effectively transmit and diffuse light, ensuring uniform illumination across different surfaces. Refraction can take place whether it travels from one medium to another or if the original medium changes at a gradual level.

To ensure light goes through your light pipe’s surface in the appropriate direction and doesn’t appear bent or broken, the Refractive Index will need to be accounted for in your light pipe design.

The formula goes like this:

N = C/V

C is the speed of the light V is the velocity of light in that medium (e.g., water, air, vacuum, acrylic, polycarbonate)

The Refractive Index demonstrates how much of the light is bent, or refracted when it hits your surface.

In a perfect world (aka a vacuum), the light breaks at a rate of 1.0. In the real world, the rates are slightly different:

Air = 1.003 Water = 1.33 Acrylic = ~ 1.49

Once you’ve calculated how the light will break or distort when shining through your medium, it’s time to figure out how to ensure the most light will end up at the exit point of your light pipe. Only there can your end-user view the light and react to whatever status it may be signaling.

To determine the best approach for making that happen, you’ll need to understand another phenomenon in physics…reflection.

Challenge #2: Sending light around corners… TIR to the rescue!

Reflecting light is essential when you want it to bend around corners in a light pipe. And the sweet spot for making that happen is called total internal reflection (TIR). Total internal reflection happens when the angle at which light is reflected when it shines through a surface is greater than a certain limiting angle known as the critical angle.

The maximum angle of refraction is 90 degrees. Rigid light pipes can move light around right angles and tight corners, making them suitable for applications requiring precise light management. After that, the entire beam of light would be reflected rather than a portion of it being refracted.

TIR can only occur when the angle of incidence is larger than the critical angle. And the critical angle will vary depending on the media the light shines through.

Because many devices that use light pipes have rounded corners where the light needs to travel to the HMI, flexible light pipes excel in navigating tight corners, providing design flexibility and efficient light transmission even through bends. Understanding how the critical angle and TIR work together is crucial for optimal light pipe design.

In the diagram above, you can see how refraction affects the ray of light as it travels from a water surface to an air surface. You can also see how leveraging TIR can help ensure the ray bounces back to the exit surface.

Most light pipes are made of either acrylic or polycarbonate. And of course, each material has its own critical angle.

Clear polycarbonate = 39

Acrylic = 42

These small degree shifts can add up to big differences in how your light pipe performs, so be sure to account for the specific properties of the light pipe material you’re using in your design.

Digging deeper, let’s see an example of how TIR would affect design for a right-angle light pipe.

The right-angle light pipe has a 45-degree reflection prism surface. Without proper calculations and preparations to achieve TIR, much of the light will be lost due to refraction instead of going around the curve to its final destination.

One way to prevent light loss is to use a light pipe that is curved to accommodate the critical angle, so all of the light reflects off the curve and shines exactly where it’s supposed to. The thickness and bend radius of the light pipe also come into play. VCC’s team of experts can help you calculate the precise angles and specifications based on your light pipe’s properties.

Reflection and TIR are just a few factors that go into effective light pipe design.

Applications of Light Pipes

Light pipes find applications across a wide range of industries, including electronics, automotive, communication, medical, industrial control, and security systems. In electronic devices, light pipes are used to illuminate user interfaces in computers, cameras, and printers, ensuring clear visibility of indicator lights. Automotive lighting systems utilize light pipes for both exterior and interior illumination, enhancing safety and aesthetics. Communication equipment, such as emergency-assistance call boxes and network switches, also benefit from the efficient light transmission provided by light pipes. In the medical field, both rigid and custom light pipe designs are employed in various devices to ensure precise and reliable illumination. Industrial control devices use light pipes to improve the visibility of LED indicators, facilitating better monitoring and control. By enhancing illumination and visibility, light pipes contribute significantly to the performance and usability of these diverse applications.

Design Considerations

When designing light pipes, several critical factors must be taken into account to ensure optimal performance. The type of light pipe, whether rigid or flexible, and the material used, such as polycarbonate or acrylic, can significantly impact the efficiency of light transmission. The distance between the light source and the exit point is another crucial consideration, as it affects the distribution and intensity of the emitted light. The angle at which the light enters and travels through the light pipe also plays a vital role in minimizing light loss and ensuring effective illumination. Incorporating total internal reflection (TIR) into the design can enhance light distribution by reducing losses and directing light precisely where needed. Additionally, using diffusers can help scatter light, creating a more even and soft illumination. By carefully considering these factors, designers can create light pipes that offer high efficiency and reliable performance.

Future of Lighting Technology

The future of lighting technology is poised to be revolutionized by advancements in light pipe design and materials. The increasing use of flexible light pipes is expected to enable more complex and innovative designs, allowing light to be directed through tight spaces and around sharp corners with ease. The development of new materials, such as advanced polymers and nanomaterials, promises to enhance the performance and efficiency of light pipes, making them even more effective at transmitting light. Integrating light pipes with other technologies, such as LEDs and optical fibers, will open up new possibilities for innovative lighting solutions. Additionally, the adoption of 3D printing and other advanced manufacturing techniques will facilitate the creation of complex light pipe designs and structures, offering easily customizable solutions. As lighting technology continues to evolve, light pipes will play an increasingly important role in creating efficient, reliable, and cutting-edge lighting solutions.

Explore our Light Pipe Design Guide

Watch the webinar VCC recently conducted on the topic or visit the light pipe design page. Ensuring optimal light transmission and user experience in the final device is crucial for achieving high performance and user satisfaction. The guide provides practical examples of how light pipes can be used to extend light’s reach, bend light, and respond well to different LED mounting types across various industries.