Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

Life Expectancy

Life expectancy of an indicator or bulb is the estimated duration of its performance. This number is typically measured in hours. Sample lamp life expectancies:

- LED: 50,000 to 100,000 hours

- Neon: 25,000 hours

- Incandescent: 1,000 hours to 1,500 hours

-

Light Diffuser

In the world of opto-engineering and light pipe design, a light diffuser can be any material that softens or diffuses the light as it transmits it.

This could be the lens of an LED or the face of a light pipe. The term light diffuser is often interchanged with light pipe.

-

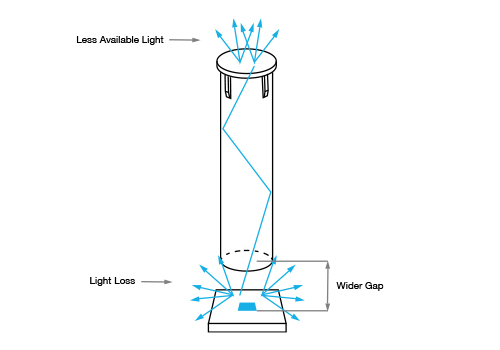

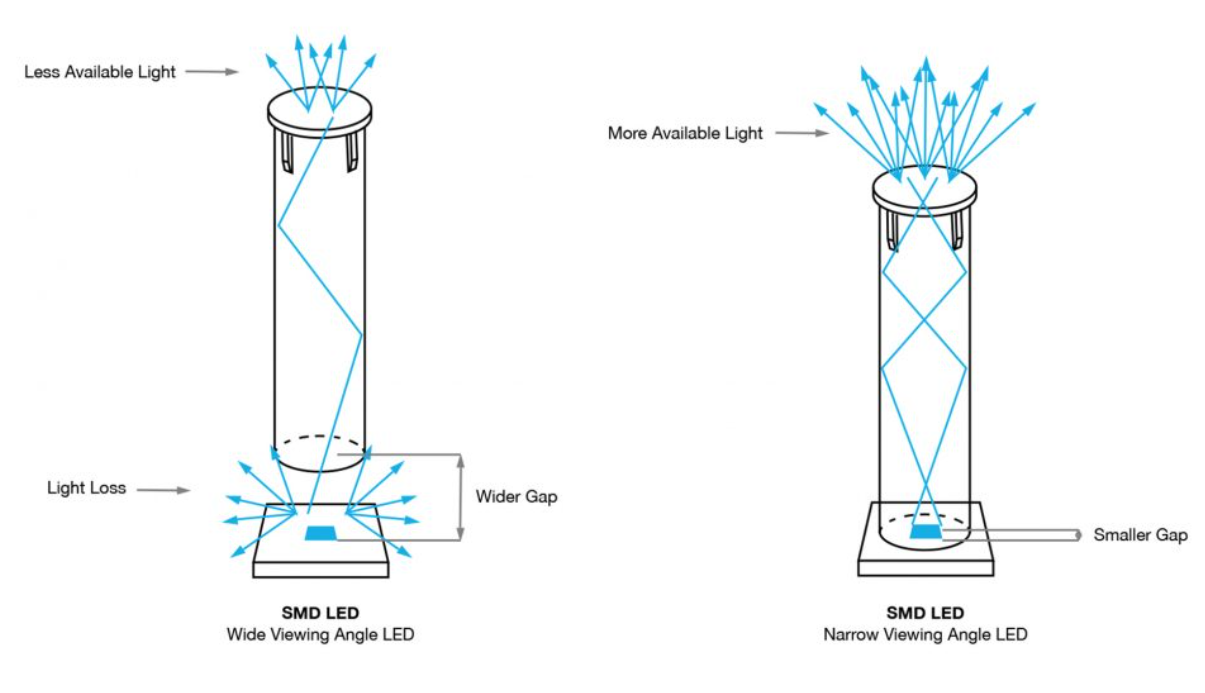

Light Leaks

Light leaks occur when some of the light that is meant to be transmitted to the exit point escapes at other places in the device, reducing efficiency and causing false readings.

Proper light pipe design techniques can be used to minimize light leaks, including spacing of the LED and light pipe, viewing angle and light pipe dimensions..

-

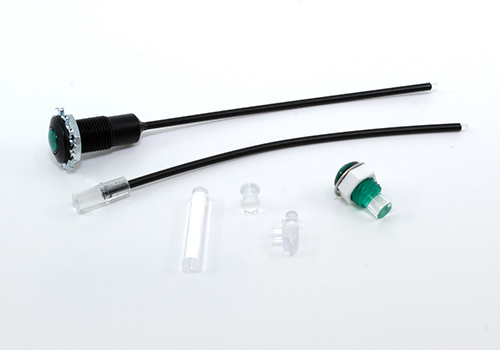

Light Pipe

A light pipe is a cylindrical rod made of glass or synthetic materials that carries light from the light source to the desired exit point.

Available in a variety of shapes, lengths, and optical characteristics, light pipes influence production efficiencies, visual communication, safety, and costs.

-

Light Pipe Position

The light pipe position is where and how it sits in relation to the light source. The closer the light pipe is to the LED or light source, the more you can minimize light loss.

A general guideline is to use an LED with a narrow viewing angle of 160 degrees or less and make sure there’s no more than 0.05” between the LED and the light pipe position.

-

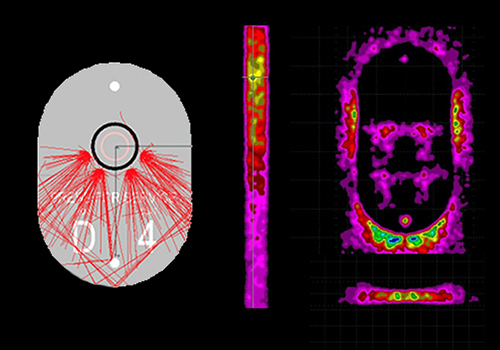

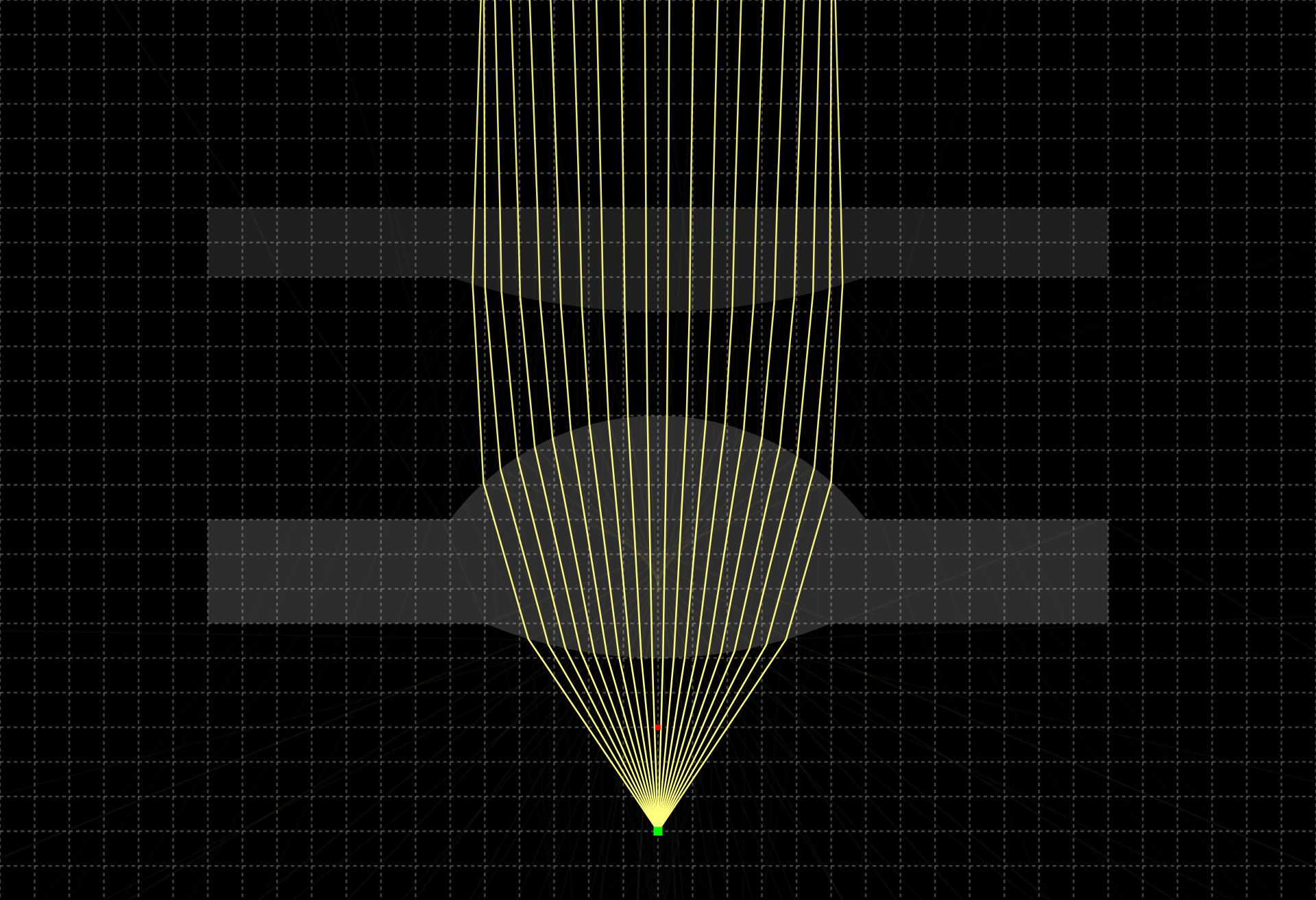

Light Ray Simulation

Optical light simulations calculate how a light pipe will perform within its device. This technique uses advanced software to project how and where any light leaks may occur.

Used for optimizing and validating the design, light ray simulation can dramatically improve the design and efficiency of a status indicator or device.

-

Long PMI Body

The body, or length of the PMI encasement or area that is threaded through the hole of the panel.

Some heavy-duty or ruggedized devices require a PMI with a longer body to accommodate the additional panel thickness, like our CDLB Series for panels up to .256” (6.5mm) thick.

-

Medium

Light pipe design requires an understanding of how light travels when it shines through a medium, or material, such as water, acrylic, polycarbonate, silicone resins, and more.

The amount of light that travels, how the light bends and other factors will vary by the medium due to a phenomenon called refraction.

-

Micro-Fit Connector Dual Row

A micro-fit connector dual row can be used to join board-to-board, wire-to-board, or wire-to-wire configurations. For production efficiencies, VCC can add a dual row micro-fit connector to indicators rather than having to outsource that step to a third-party.

-

Minimal Light Loss

In light pipe design, minimal light loss is the ultimate goal.

While there will always be some minuscule amount of light loss, minimizing the light loss, or light bleed, is achieved with proper design and testing.

-

Moisture-Sealed Light Pipe

There are many indoor and outdoor applications where an indicator may be exposed to moisture — from raindrops to harsh cleaning chemicals.

A moisture-sealed light pipe is one that includes additional security measures designed to keep moisture out so it doesn’t hamper performance.

-

Mounting Hole Sizes

Mounting hole sizes are used to determine the appropriate PMI to accommodate a panel or interface. Every product will vary slightly in size.

VCC offers indicator mounting hole sizes ranging from 0.16” (3.98mm) to 0.88” (22mm). PMIs with custom mounting hole sizes are available if a minimum quantity is ordered.