Case Study

VCC cooks up quick custom solution for ventless grill manufacturer

Application Characteristics

Not surprisingly, commercial kitchens require the utmost in safety standards. Most grills and griddles require a type 1 hood, which must meet fire and safety standards. These commercial vents are pretty steep to install, running an average of $964 to $1174 — per linear foot.

Complying with such stringent standards is cost-prohibitive for many smaller foodservice operations. To address this common pain point, ventless cooking products are in demand, and deemed the way of the future.

Commercial-grade griddles with built-in ventilation and fire suppression systems enable kitchens of all sizes to offer everything from burgers to breakfast items without breaking the bank on costly type 1 hood systems.

Solution / Approach

Because VCC already has thousands of innovative illuminated components available, our design team quickly found the ideal solution. Somewhere between a standard product and a custom design, we helped our client get the best of both worlds.

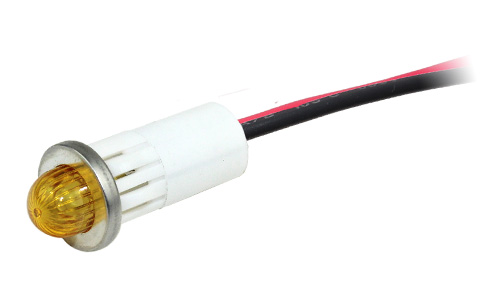

We created a 250V version of our amber 1092 Series LED panel mount indicator (PMI) with wire leads to meet all of the client’s design requirements, including:

• High-voltage operation – By increasing the power to 250V, we helped our client achieve the desired power level while eliminating the 12V converter and costs associated with an extra component.• Unbeatable bulb life – While there were 240V solutions readily available, they were neon and did not provide the operating life the client was looking for. Our LED will provide reliable indication for up to 100,000 hours.

• High brightness and visibility – The 1092 Series achieves full brightness in microseconds, and the high-hat lens provides superior viewing from 180 degrees.

• Protection from moisture and grease – To ensure food safety and protection from grease and harsh chemicals, the 250V PMI included a gasket that meets ASTM 2000 standard.

• Cost-effective assembly – For faster, more efficient installation, the PMI snaps into a.500” (12.7mm) diameter hole without additional hardware.

Application Requirements

A leading ventless grill manufacturer approached us with a unique design challenge. The client wanted to optimize its high-efficiency grill design with a solution that met the following requirements:

• High-voltage operation of 240V• Reliable, long-lasting indicator

• 180-degree viewing angle

• Ruggedized construction

• Streamlined manufacturing and assembly

Results & Benefits

VCC helped the client optimize its high-efficiency grill for an even better end-user and operator experience by:

• Eliminating the need for a converter drove down overall manufacturing costs• Simplifying indicator assembly

• Enabling faster visual communication

• Delivering up to 100,000 hours of reliability

• Providing safe, convenient operation

Value-added Service

Our team modified one of our standard products to deliver a faster and more cost-effective solution than a fully custom project.

Whether you need a simple design tweak, custom design or something in between, we have the expertise to help you get there.