Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

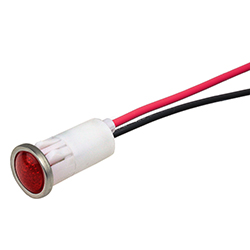

Sealed Indicator

A sealed indicator is a PMI or light pipe that has added reinforcements to keep out dust and moisture.

Methods for sealing include accessories, design features such as O-rings, gaskets, hex nuts, and D mounting styles.

-

Semi-Dome Face

A semi-dome light pipe face is the middle ground option between a full dome and a flat face that is flush with the panel. The semi-dome face provides a wide viewing angle and helps minimize hot spots that could disrupt visual communication.

-

Semi-Dome Lens

PMIs with a semi-dome lens split the difference between a full dome and a flat lens face.

The semi-dome shape provides some of the advantages of a rounded lens without being too prominent on the panel, minimizing hot spots while providing a wider viewing angle.

-

Shorter Supply Chains

Global supply chains are full of risk, as delays at any point in design, production, manufacturing, and shipping could cause severe financial loss.

By choosing nearshore suppliers, OEMs can take advantage of shorter supply chains which mean less distance products need to travel, saving time, money and potential disruptions.

-

Silicone Resins

Another material available for light pipe fabrication, silicone resins are also used for LED lenses.

For outdoor applications or medical equipment, silicone resins are a great solution because they don’t yellow under UV and are safe when applied to skin.

-

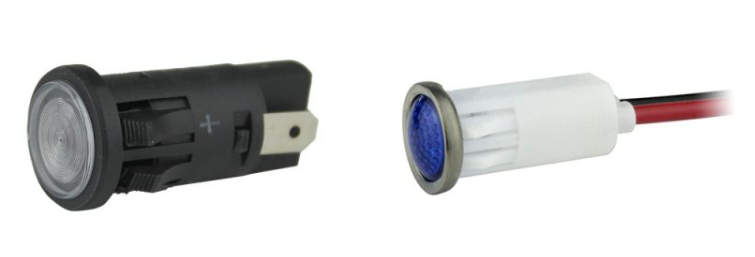

Snap-Fit

Snap-fit is a PMI mounting style where the PMI rests inside the panel mounting hole and snaps into place with a metal connector (rather than using wires).

Because the PMI can fit securely to the HMI without additional hardware or steps, snap-fit panel mount indicators can save time and money during production.

-

Snap-Fit with “D” Mounting

Snap-fit with “D” mounting is an attachment method where the PMI is inserted into a D-shaped mounting hole on the panel.

The shape helps protect the device from rotating or coming loose due to vibration. Ideal for industrial applications, the snap-fit with D mounting is simple to install.

-

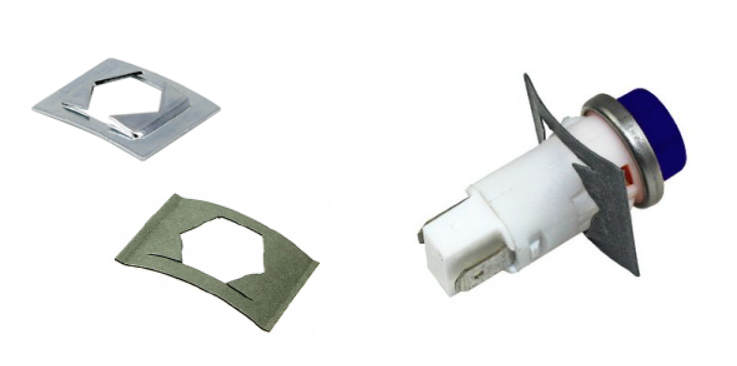

Speed Nut

A speed nut is a push-on accessory for panel mount indicators that helps protect them in high-vibration working environments.

Sometimes the speed nut is included with the PMI, others, it’s an add-on part. Refer to the specific product’s datasheet for details.

-

Storage Temperature

Not to be confused with operating temperature, the storage temperature is the range at which the light pipes can be warehoused with minimal degradation.

In low-heat, low-humidity environments, storage temps for acrylic and polycarbonate light pipes are typically between -100℃ and 25℃. Always refer to manufacturer specifications.

-

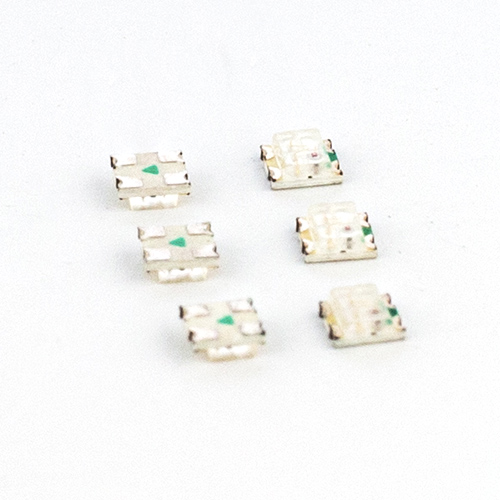

Surface-Mount LED

A surface-mount LED is one that affixes to the PC board. Also called surface-mount devices (SMD) LEDs, these components can provide efficiencies during installation and assembly.

Because SMD LEDs don’t contain wire leads, they are soldered directly to circuit boards using tiny metallic contacts.

-

Surface-Mount Technology

AKA: SMT

Surface-mount technology or SMT is the method used to attach surface-mount LEDs or other electrical components on a printed circuit board’s surface. SMT delivers a range of benefits for OEMs and designers, including:

- Reduced size

- Lighter weight

- Cost efficiencies

- Design flexibility

- Automated production

-

Surface, exit

A light pipe contains two openings: one at the light source, and one where the light needs to shine at the interface or control panel.

The location where the light shines out is the exit surface.