Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

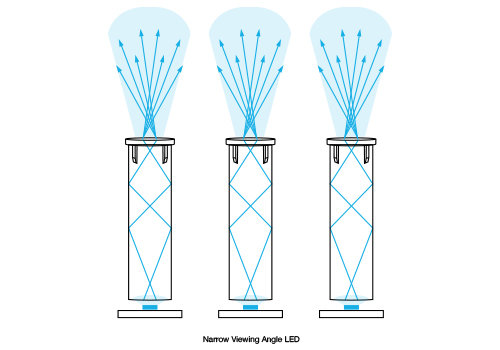

Narrow Viewing Angle

Viewing angle can indicate how focused the light will be. It’s determined by several factors, including device design, spacing of LED and the light pipe, and lens face or shape.

As a general rule, LEDs with narrow viewing angles are ideal for illuminating a small area on the panel, or if the light needs to travel longer from the LED to the exit surface.

-

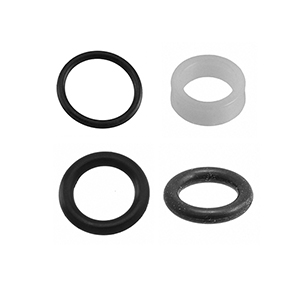

O-Ring

An O-ring is a gasket that goes around the indicator at the panel to keep out water, dust, debris, oil and other contaminants that could impact performance.

-

Operating Temperature

The operating temperature is the range for the safe use of an indicator or light pipe. Factors like humidity, weather and stress can have a huge impact on operating temperature.

In low-stress working environments, operating temperatures typically range from -100℃ to 100℃ for acrylic and -100℃ to 125℃ for polycarbonate.

-

Panel Mount Indicator (PMI)

A panel mount indicator is a status indicator that affixes directly to the control panel or HMI instead of the inner components of the device.

PMIs are ideal for control panels with only a few status indicators and come in a variety of colors, sizes, mounting styles. Features such as lens shape can determine visibility.

-

Panel-Mount Light Pipes

The opposite of board-mount light pipes, panel-mount light pipes are affixed to the control panel of the device instead of the PCB board.

Panel-mount light pipes can be attached to the panel or HMI using “crushable” ribs or a retainer ring to seal the surface. Examples: LFB Series, LFC Series, LMC Series, LPCR Series

-

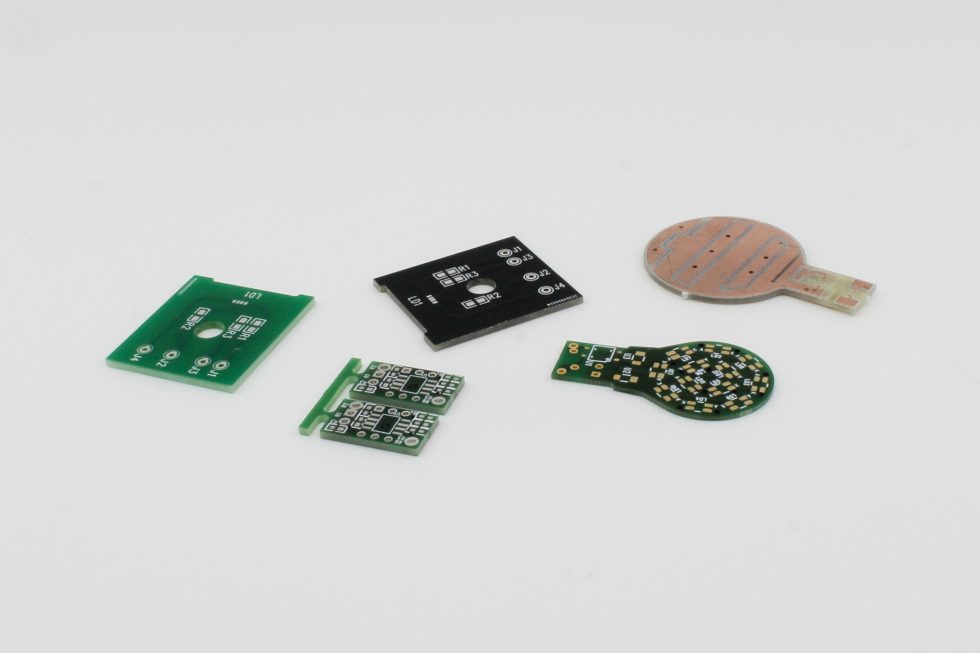

PCB

A printed circuit board or PCB is a board that acts as the foundation of a device. It holds a chip or other electronic components in place.

To address a range of design requirements, PCBs can be single-sided, double-sided, rigid, flexible, multiple layers, various shapes, and linked together in a single device.

-

PCBA

A printed circuit board assembly, or PCBA, is the printed circuit board with all of the electronic components installed, typically by soldering them.

PCBAs are made up of several layers, each with its own job connecting the proper electrical charges to the right switches and other components.

-

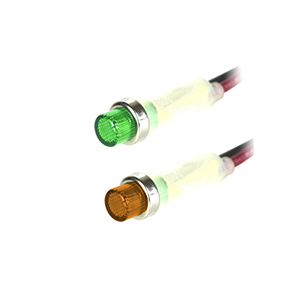

Pilot Light

A pilot light is an illuminated lamp used to communicate a device’s status with end-users.

Commonly referred to as a panel mount indicator, this light can leverage LED, incandescent or neon technology to communicate machine function.

-

PMMA

PMMA (polymethacrylmethylimid) is a material that can be used to make light pipes. It isn’t as malleable as acrylic or polycarbonate.

Because of PMMA’s thermal resistance up to 170°C, the material is best suited for devices with heavy thermal loads.

-

Polycarbonate Light Pipe

Polycarbonate, or PC, is one of the most popular materials used to make light pipes due to its relative low cost and benefits.

PC light pipes offer excellent light transmission, low UV transmission, can be easily molded, and are durable and scratch-resistant.

-

Press-Fit

Press-fit is a mounting style where the PMI is attached to the panel using friction to create a secure bond.

The indicator is pressed to the panel rather than using hardware to mount it in place.

-

Prominent Bezel

A bezel is the housing or encasement around a panel mount indicator that can be made of steel or plastic.

A prominent bezel is one that is longer and/or wider, typically to accommodate a thicker panel or for aesthetic purposes.