Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

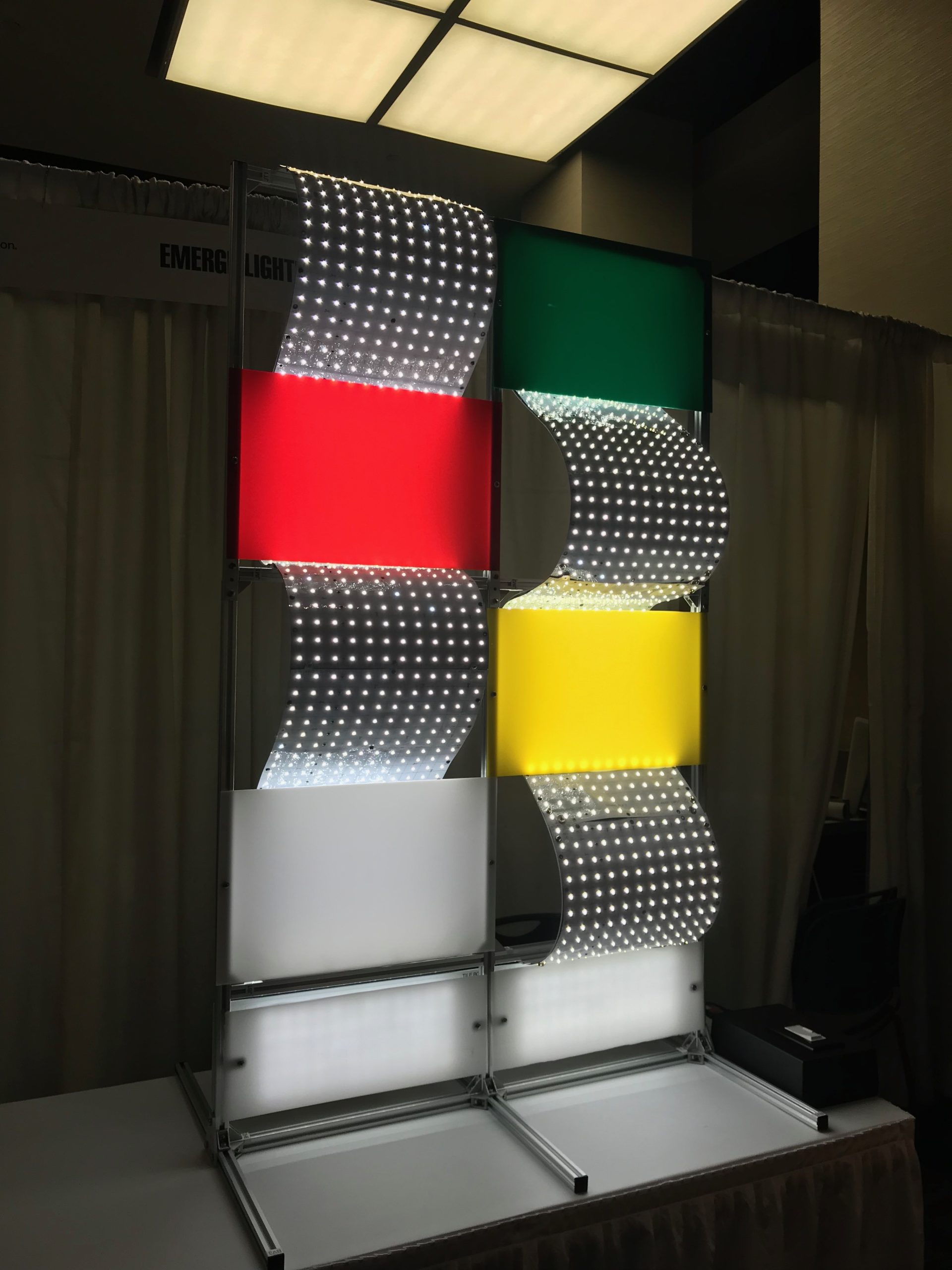

Illuminated Communicator Control Panel

AKA: Control Panel, HMI

The illuminated communicator control panel is the interface of a machine or device where the end-user can view the machine’s status. It’s also called a control panel or human-machine interface. Using color, images and icons, the illuminated communicator control panel helps the user operate the machine safely.

-

Illuminated Communicator Control Panel

Also called a control panel or human-machine interface (HMI), the illuminated communicator control panel is the interface of a device where the user can view the machine’s status.

Through the use of color, images and icons, the illuminated communicator control panel helps the user operate the machine safely.

-

Illumination Intensity

The illumination intensity of an LED or PMI is how bright the light shines. Intensity can be measured in many ways – watts, lumens, wavelengths, or even candelas, to name a few.

Several factors contribute to the overall intensity of an LED, from the number of candelas or watts to the viewing angle of the lens.

-

Incandescent Indicator

An incandescent indicator is a status light that uses the same tech used in a traditional light bulb.

While cheaper than LEDs, incandescent indicators require more energy and burn out faster. OEMs often retrofit incandescent indicators with LED technology for enhanced efficiency.

-

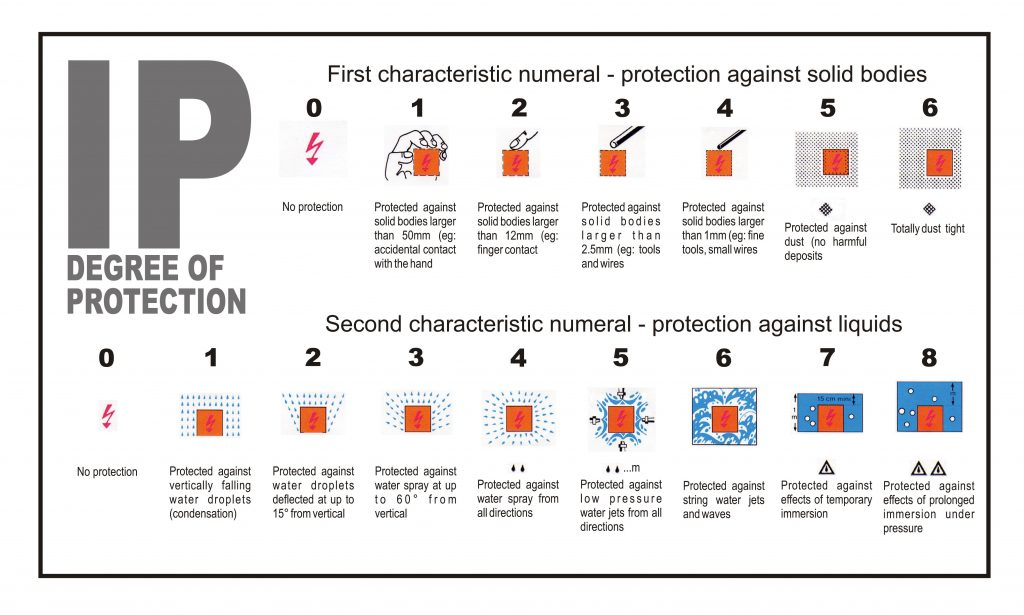

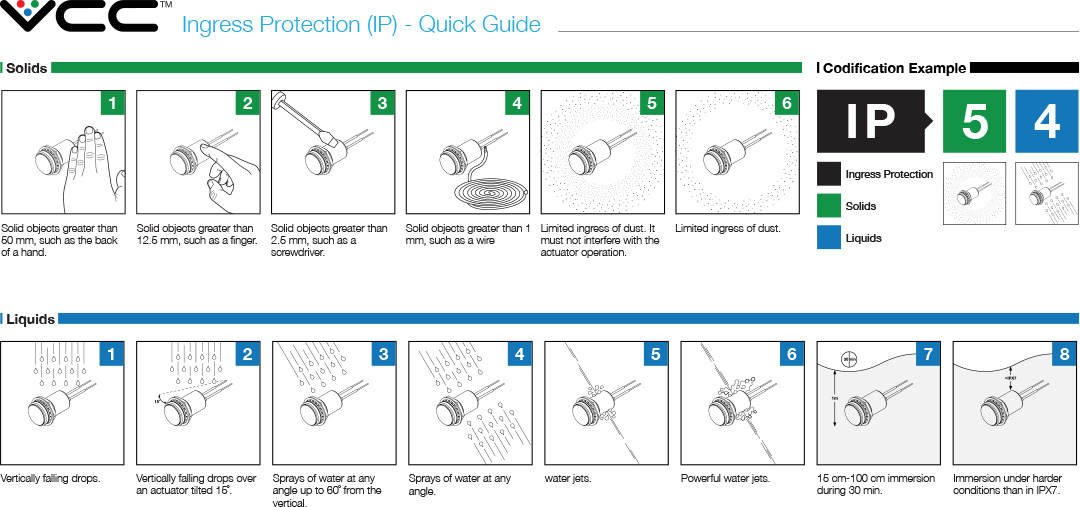

Ingress Protection or International Protection Ratings

Ingress Protection or International Protection is a rating system used to indicate how protected a PMI is from both solids and liquids based on a numeric scale. Example: IP54

Solids are rated in the first number on a scale from 1-6. Liquids are rated in the second number on a scale from 1-8 The higher the number, the greater the protection.

-

IP Rating

The IP rating or ingress protection rating is a numerical system used to indicate how protected a component is from particles such as dust or moisture.

The first number indicates the level of protection from solids, and the second indicates the level of protection from liquids. (The higher the number the better.)

-

Lamp life

A bulb’s lamp life is the estimated duration of the light’s performance, as measured in hours.

For LEDs, the lamp life is typically 50,000 – 100,000 hours, while an incandescent bulb’s lamp life may be 1,000 hours.

-

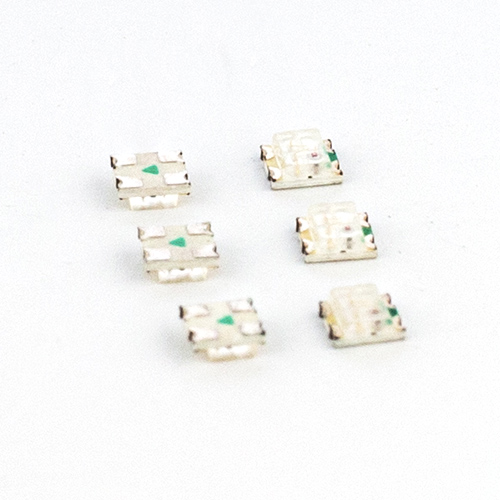

LED

An LED is lighting technology that uses light-emitting diodes to illuminate a bulb. LEDs are very popular in indicators of all industries because of their properties and benefits.

From brightness and reliability to long life and energy efficiency, LEDs are the ideal technology for design flexibility in most applications.

-

LED Adapter

Depending on the design of the device, an adapter may be used to secure the LED to the light pipe. Different adapters may be needed for through-hole and surface mount LEDs.

-

LED Holder

LED holders are the foundation of a panel mount indicator, used to encase the LED lamp for attachment to the device.

Mounting hole diameter, working condition, and other design considerations help determine the appropriate LED holder. Some include additional accessories for moisture protection.

-

LED Light Pipe

An LED light pipe is a tube made of plastic, acrylic, or glass that sits over an LED on one end of the device and carries light from the light source to the control panel or HMI.

LED light pipes come in a range of colors and lengths, plus mounting options with their own pros and cons. For additional info on light pipes, check out our light pipes or FAQs page.

-

Lens Shape

LED lenses, or the caps at the top of them that are visible on the HMI, can take multiple shapes.

Each one has its own benefits for the end-user, including high daytime visibility, wide viewing angle, diffusing the light/uniform illumination, and aesthetic appeal.