Glossary

Explore our curated list of essential terms related to the design, engineering, and production of light pipes, panel mount indicators, and LED displays.

The Ultimate Status Indicator Glossary

Deepen your understanding of the concepts, terminology, and product names we use in the world of VCC. We encourage you to bookmark this page and revisit regularly, as we continually update it with new definitions.

-

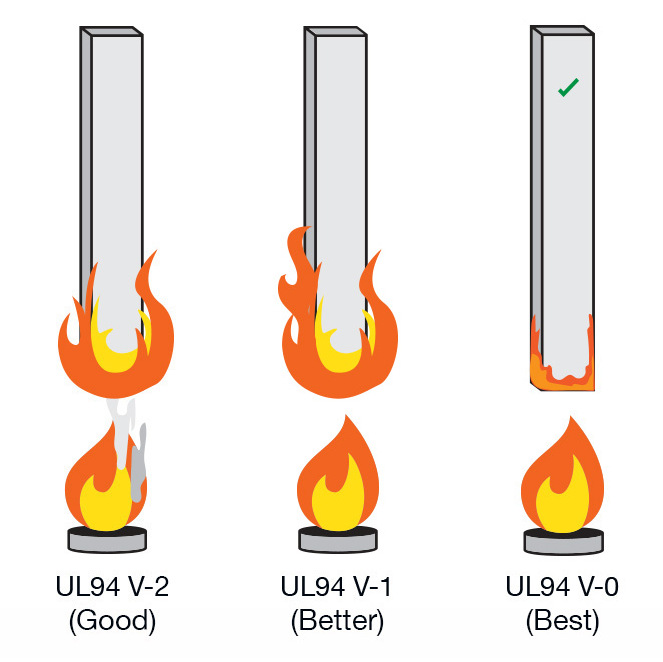

Flammability Rating

Determined through a series of tests, the flammability rating is used to calculate the UL94V-0 flammability standard — the industry standard for the safety of our products.

A flame is held to a component for a specified amount of time, then UL assesses how the product reacts to the applications and gives it a rating from V-0 to V-2.

-

Flat Face

When a light pipe has a flat face, its exit surface does not include a dome or semi-dome shape. Instead, the face is flush with the panel, which can provide a sleek, modern design.

When the light needs to travel a longer distance from the PCB or hot spots are a concern, a flat face focuses the light while delivering a 160-degree viewing angle.

-

Flex Voltage

Flexible voltage products are those where the power consumption can accommodate a range of voltage instead of a fixed power setting. Indicators with flex voltage, like our PLM50 Series, reduce inventory costs by allowing OEMs to purchase only one indicator for use in multiple designs with varying power needs.

-

Flexible Light Pipe

Light pipes typically fall into two main categories: flexible or rigid. Flexible light pipes are made to bend and move to carry light around corners and even sharp angles.

They’re also helpful when light needs to travel longer distances from the PCB or light source to the panel.

-

FlexVolt Technology

To accommodate a range of power needs in a single indicator, VCC developed FlexVolt technology for panel mount indicators and light pipes.

With ranges from 5V to 28V, FlexVolt tech provides greater flexibility for engineers and OEMs alike.

-

Flush Lens

A wide flush lens is an indicator lens that is attached to an HMI or control panel.

It’s level or “flush” with the panel opposed to a raised indicator lens that would stick up above the panel’s surface.

-

Fresnel Pattern Lens

Fresnel lenses can also soften the light beam and can be used in conjunction with various lens shapes like semi-dome, dome, or flat.

HMIs that use light pipes or PMIs can leverage the Fresnel lens to meet design and optical requirements.

-

Hi-Hat Lens

A hi-hat lens is an indicator cover that extends well beyond the surface of the control panel or HMI in a consistent shape with a flat top.

Benefits of a hi-hat lens include a wider viewing angle that can also increase daytime visibility.

-

High-Dome Lens

A high-dome lens is an LED indicator cover that sits prominently above the plane of the control panel and is rounded at the top.

The dome shape provides the widest viewing angle, improving visual communication when end-users need to maintain status from multiple positions, such as standing or bending down.

-

High-Vibration Environment

Some machines naturally move and vibrate during operation. For example, heavy industrial machinery can encounter a lot of vibrations during operation.

To help keep indicators in place, accessories like hex nuts can be added. Mounting type and device design can also prevent indicators from shifting in high-vibration environments.

-

HMI

The HMI, or human-machine interface, is the control panel or surface where the indicator(s) of a device visually communicates the status to operators.

-

Hotspot

Proper light pipe design ensures uniform illumination. When part of the indicator shines brighter than the rest, that is called a hot spot.

In some applications, a hot spot can cause errors in readings and operations, depending on the design. Techniques such as using a Fresnel lens can help reduce hotspots.