Light Bleed: Here’s What You Need to Know

Light pipes are essential for moving light from Point A to Point B in electronic devices and machines. But, when they aren’t optimized, a majority of the light traveling through them could literally miss the mark — your HMI [human machine interface]. These acrylic or polycarbonate marvels can be much more complicated than they seem. Engineers have a lot to learn about light pipes, including:

Formats

Light pipes come in many varieties, but most can fall into one of two categories: rigid or flexible. Rigid light pipes are intended to move light short, straight distances, while flexible light pipes can illuminate around curves and angles at longer distances.

Mounting Options

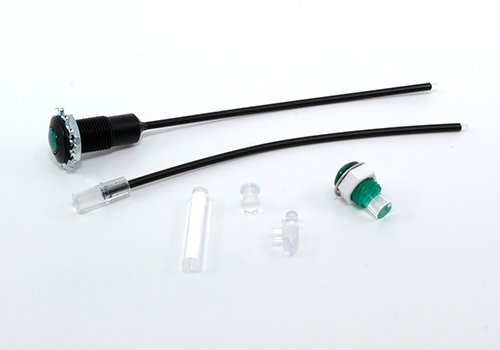

because light sources can be attached to devices in a range of ways, there are multiple options to accommodate those design decisions:

- Press-fit – rigid light pipes are mechanically attached to the front panel (chassis)

- Board mount – these light pipes are attached to the circuit board where the LED fits inside the flexible or rigid design.

- Surface mount – flexible light pipes can be mounted to the control panel of the device

LED Specifications

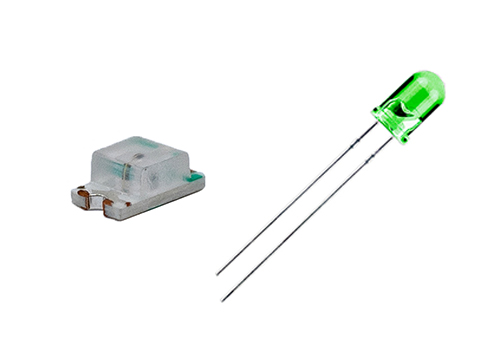

LEDs come in more configurations than most of us could count, such as:

- Type (surface mount, through-hole)

- Color

- Intensity

- Lens type

- Size

- Viewing angle

Together, these factors determine how well a light pipe will perform in its device and operating environment. The ultimate goal in light pipe design is to optimize light transmission and minimize light bleed.

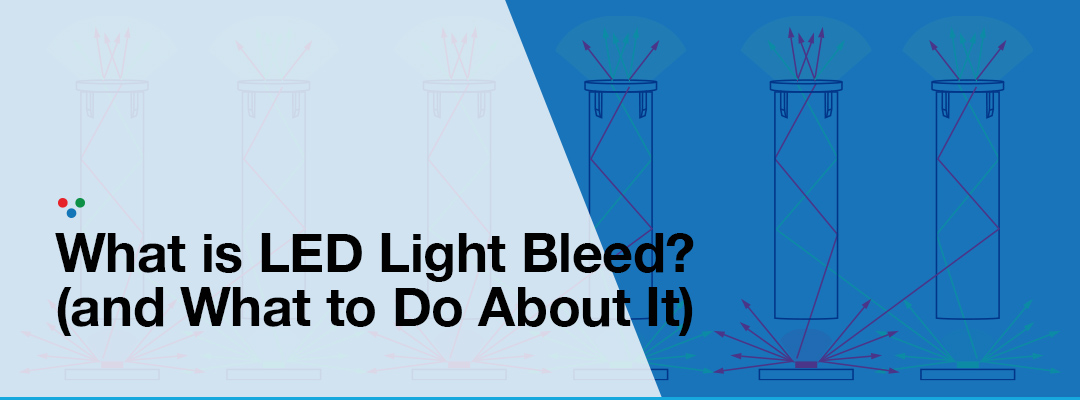

But First, What’s Light Bleed?

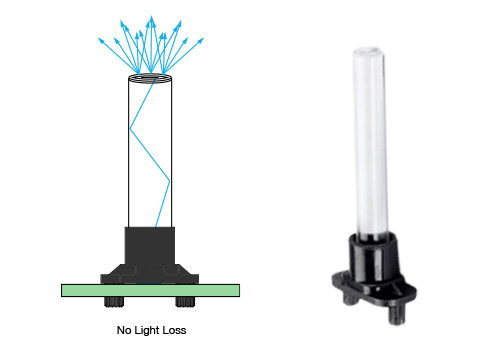

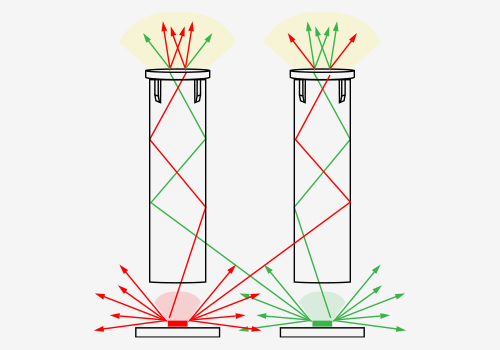

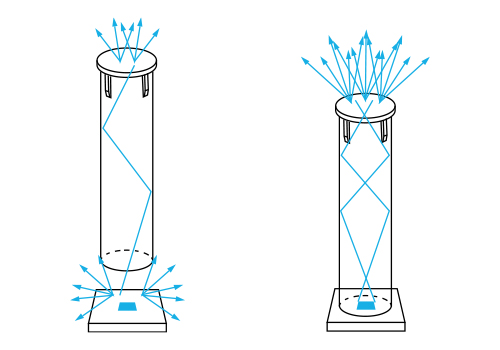

Also known as “light loss,” light bleed occurs when light escapes from the LED/board to anywhere other than its desired exit point.

LED Light Bleed’s Negative Impacts

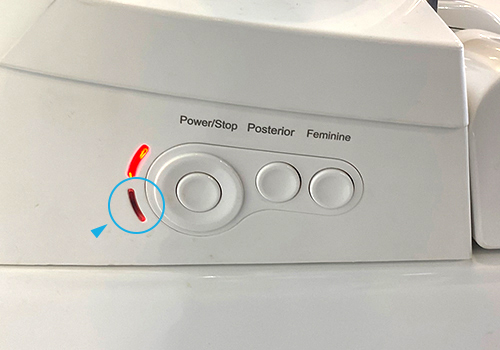

When a product has light bleed, it definitely cheapens the device and diminishes the user experience. However, light leaks can create issues that go beyond aesthetics, causing operator confusion and increased safety risks:

- Various LED colors shining over each other on the interface

- An unwanted glow where there shouldn’t be one

- Colors mixing together to create a new color not used in the visual vocabulary

- False readings

Unwanted Glow in the Chassis

Cause False Readings

Multiple LED Light Bleeds

Choosing the Best Material for My Design

Light bleed can pose challenges for a variety of devices and industries. Fortunately, there are design techniques that minimize or eliminate light bleed. To help ensure the best possible outcome in regard to performance, end-user experience (and sometimes costs), design decisions should be made as early as possible. Approaches to reduce light loss include:

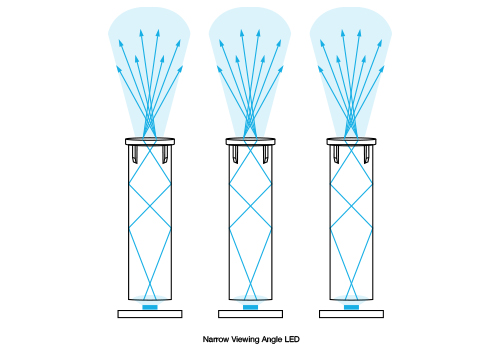

Use the optimal LED viewing angle for your design

Utilizing a narrow viewing angle instead of one with a wider range can reduce the space where light could escape and cause bleeding. We recommend using a viewing angle of 160° or less to reduce light leaks.

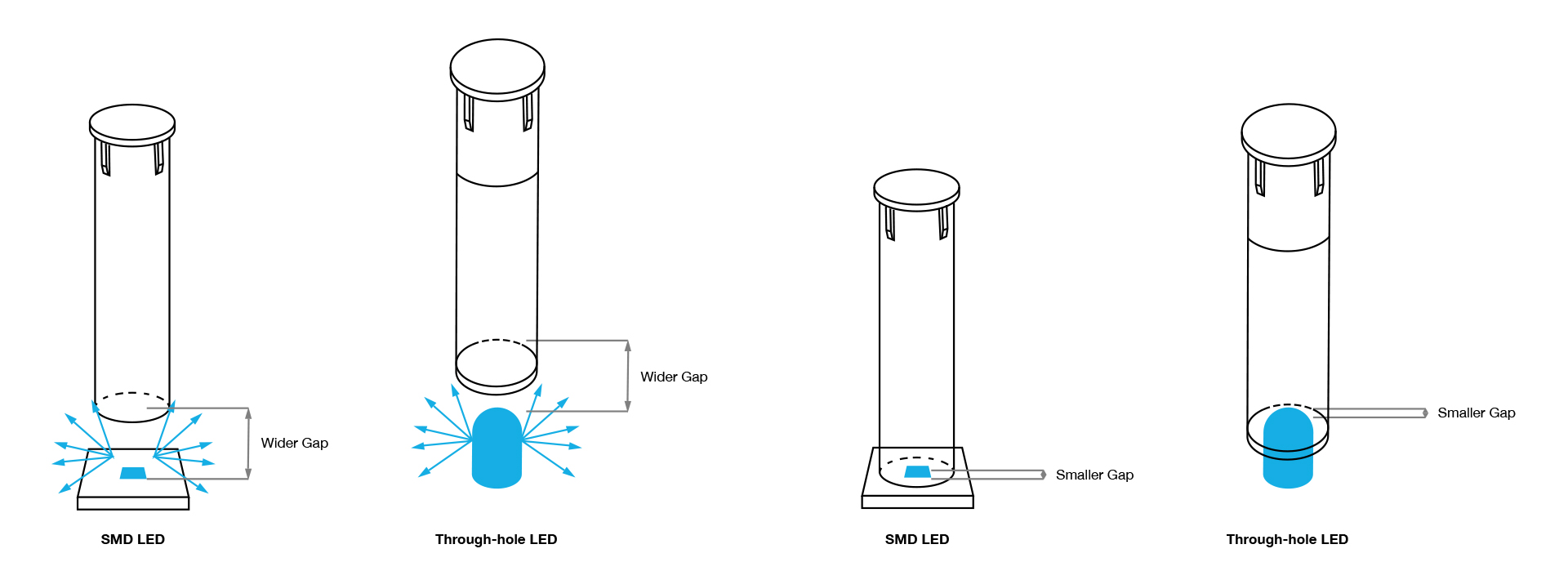

Adjust the distance between your light pipe and LED

Having too much space between the light source (LED) and the light pipe is another opportunity for light to escape. For best results, space the LED and light pipe no more than .05” apart.

Choose the appropriate light pipe for the job

VCC’s No-Bleed Light Pipe – this unique solution empowers designers and OEMs to avoid light bleed at the circuit board thanks to its snap-in base, low profile, and vertical rigid design with a Fresnel lens. The LPCM light pipe is also available with an SMD retainer that delivers greater control over where the light is directed, making it ideal for devices with multiple light pipes that could otherwise bleed into one another. Multi-unit light pipe – designed exclusively to prevent light loss where more than one LED and light pipe are located near each other on the board or interface. Custom light pipe solution – to maximize performance, VCC can conduct ray tracing simulations and design a light pipe tailored to your exact specifications and design constraints. Follow these tips, and you could be on your way to zero light bleed for your device.