FAQs

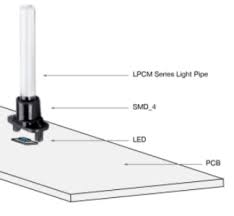

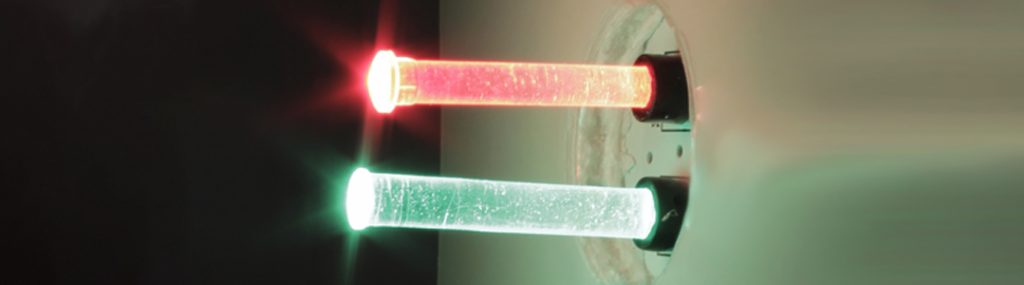

An LED light pipe is a rod made of acrylic or plastic that is used to transmit light from the light source at the printed circuit board (PCB) to the indicator panel of a device.

Light pipes are cost-effective illumination solutions that provide consistent illumination and design flexibility. They typically fall into two categories:

Rigid light pipes – polycarbonate acrylic rods transmit light from a stationary position that connects the PCB and interface

Flexible light pipesr optic rods can carry light around curves and in tight spaces to connect the light source and the user interface

VCC offers clients an extensive light pipe portfolio with solutions for essentially every need and design configuration.

If your product requires a custom design, our team can develop the ideal solution, then test and prototype it before production.

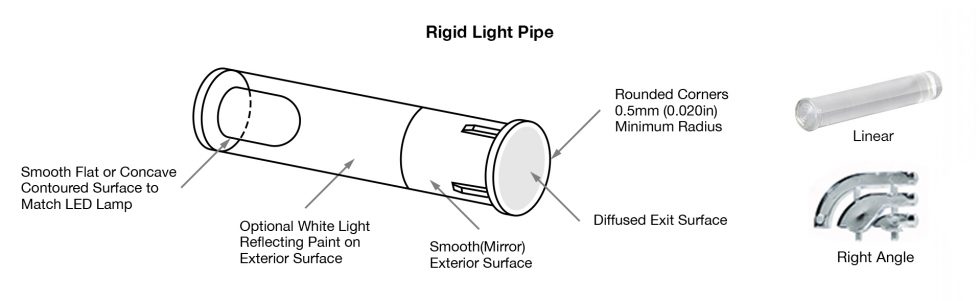

Rigid – light pipes made of optical-grade polycarbonate or acrylic that can be vertical or right-angle in orientation. Rigid light pipes are designed to move light short distances.

Flexible – light pipes made of fiber optic material that can be bent to up to 30 degrees to accommodate the design. Flexible light pipes are designed to move light longer distances than rigid versions.

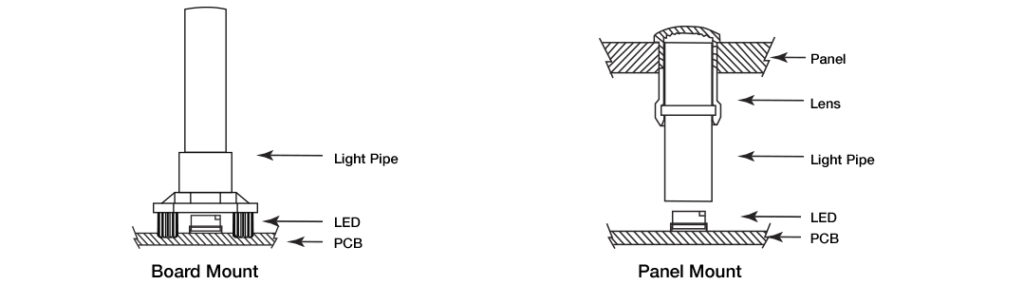

Board mount – light pipes that are mounted to the printed circuit board (PCB) at the power source of the device. VCC offers board mount products for rigid and right angle light pipes.

Surface mount – light pipes that are mounted to the control panel of the device instead of the PCB. VCC offers both flexible and rigid light pipes that can be surface mounted.

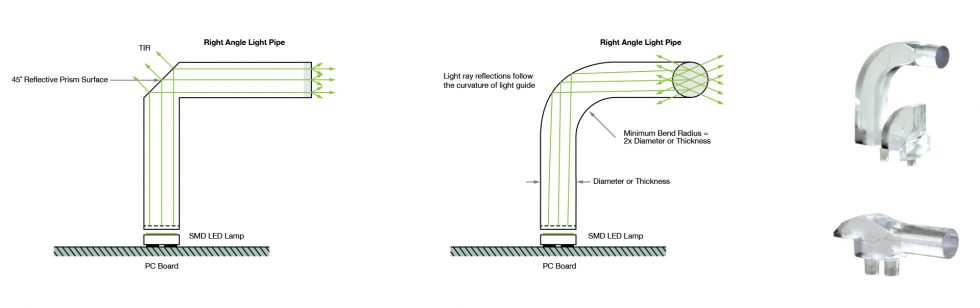

Right angle – rigid light pipes made exclusively for 90-degree angle alignment to the LED or board. VCC offers right angle light pipes in 1-position, 2-position, 3-position and 4-position board mount options.

Press-fit – light pipes that are installed directly to the indicator panel, allowing for efficiencies in production due to a press-fit design.

Moisture-sealed – for harsh environments including outdoors, VCC offers a range of light pipe solutions with added protection from dust and moisture for rigid, flexible, board mount, panel mount, right angle and through hole designs.

For additional information, download VCC’s light pipe brochure.

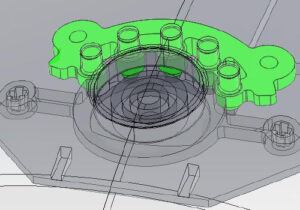

Custom made to specific applications

VCC can design custom light pipes to your specific needs and applications, allowing you to have total control over your illumination. Our team can design and run light simulations to determine optimal performance while reducing hotspots and light leaks, then develop a custom light pipe to fit your ideal illumination specifications. In most cases, a MOQ is required for a custom light pipe. Another alternative would be modifying an existing light pipe design by replacing materials, length or light characteristics.Contact VCC to learn more.

A light pipe is more complex than it seems, with several features and options that all affect how much — and how well — the light travels through the light pipe.

For example, rigid light pipes will include:

Rounded corners – this feature helps minimize light loss or escape.

Diffused exit surface – to provide more uniform illumination, a diffused surface is used at the point where light is seen by the end-user or operator at the HMI.

Smooth, flat, or concave contoured surface – whichever properties the LED itself have should be mimicked by the interior surface of the light pipe. The LED and light pipe must work together to get the most light possible to travel through to the other end, the exit surface.

Reflecting paint on the exterior – an optional add-on that helps reflect more light is to add white paint to the exterior of the light pipe.

Together, these are a few of the attributes that add up to light pipe performance. For more information on how light pipes work and best practices, check out our Light Pipe Design Guide.

VCC can customize our existing light pipe products, depending on the application, requirements and light specifications needed.

In some cases, a fully customized solution may be more cost-effective than modifying an existing design.

Our team is happy to assist you in exploring customization options for your light pipe needs.

There are several factors that can impact the percentage of light being transmitted, including the viewing angle of the LED.

Designers can expect the light pipe to transmit roughly 80 to 90 percent, depending on the design. This amount does not change whether your light pipe is made of optical-grade polycarbonate or optical-grade acrylic.

The storage and operating temperature will vary by the type of material the light pipe is made from.

Storage temperature – as a general rule, polycarbonate and acrylic light pipes can be stored at temperatures ranging from -100℃ to 25℃ with minimal degradation. The lower the temperature and humidity, the less degradation of the device.

Operating temperature – this will depend on how much strain is put on the light pipe in its environment. If there is very little stress, the operating temperature can range from -100℃ to 100℃ for acrylic and -100℃ to 125℃ for polycarbonate.

All other light pipe materials should be determined on a case-by-case basis. Refer to the data sheet of each individual product or contact VCC to obtain specific temperature information.

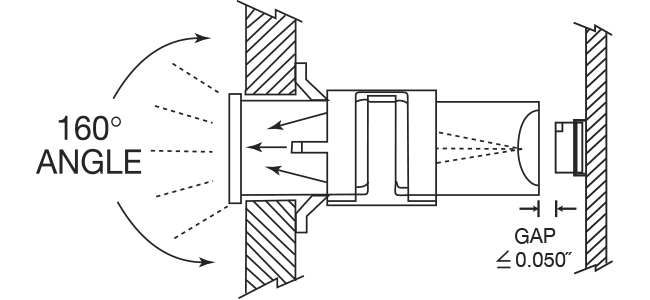

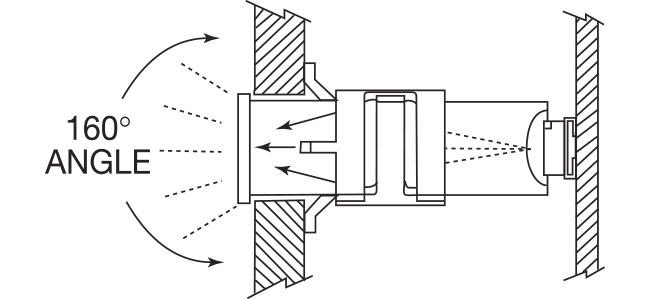

To minimize light bleeding, use an LED with a narrow viewing angle of 160 degrees or less, and position the light pipe and LED no more than .05” apart.

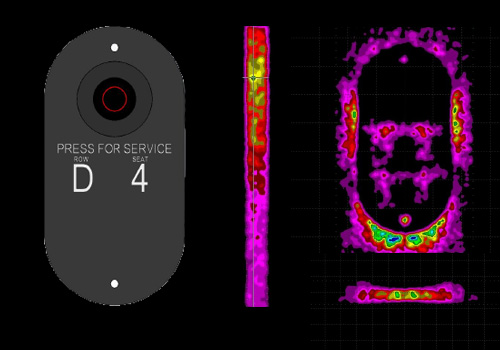

The VCC team specializes in running light simulations to determine how light will behave in light pipe prior to production. We can test standard products or create a full custom design and prototype to suit your needs.

Press-fit light pipes can greatly improve manufacturing efficiencies since only access to the front of the panel is needed during assembly. OEMs can utilize automation to pick and place the light pipes into the panels instead of costly and time-consuming manual labor.

VCC’s light pipes deliver maximum design flexibility, and are compatible with a variety to types of LEDs.

In addition to versatile mounting options, our light pipes provide additional flexibility because physical contact between the light pipe and LED is not required.

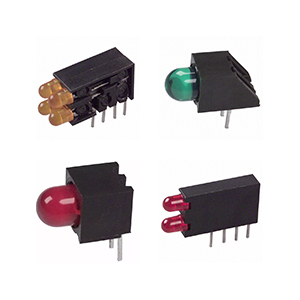

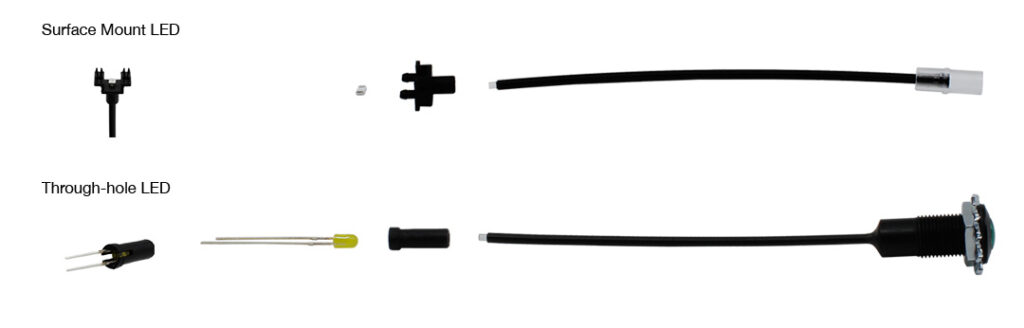

Light pipes are compatible with four mounting types of LEDs:

Through-hole LEDs

Flexible light pipes work well with through-hole LEDs and can be mounted from the panel or the back of the device.

Right-angle through-hole LEDs

Right-angle through hole LEDs work well with flexible light pipes that are mounted to the PC board or panel.

Surface mount (SMD) LEDs

For LEDs that are surface mounted the the panel, flexible and rigid light pipes are options available.

Right-angle surface mount LEDs

Flexible right-angle light pipes that are mounted to the PC board are ideal for right-angle surface mount LEDs.

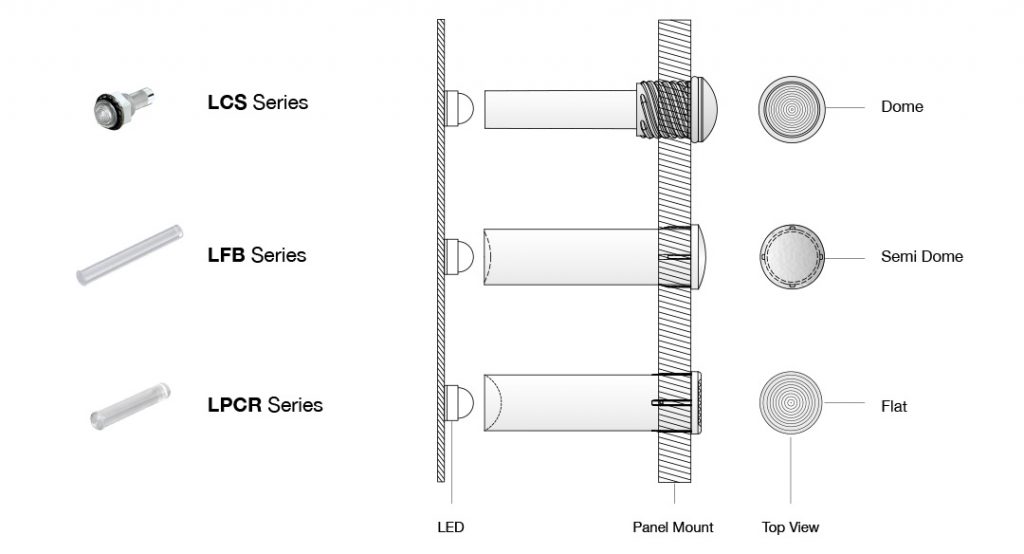

VCC’s rigid light pipe faces are available in three different shapes: dome, semi-dome or flat, each with their own benefits.

Dome – provides the widest viewing angle and best visibility from different working positions. A dome shape is ideal when the indictor must be viewed from the side view as well as straight on. VCC’s LCS Series is available with a dome face that also includes a Fresnel surface, which helps focus the light.

Semi-Dome – when less-intense illumination is needed, the semi-dome light pipe face minimizes hot spots while providing a soft glow while still allowing for a wide viewing angle. For example, the LFB Series semi-dome delivers 120-degree viewing and a frosted glow.

Flat – in applications where hot spots are a concern or the light needs to travel a long distance from the PCB to the panel, a flat shape is the perfect solution. It focuses the light into a more concentrated beam while providing a 160-degree viewing angle. VCC’s LPCR Series combines the intensity of a Fresnel lens with the flat, low-profile design.

Ray tracing is suggested to ensure you provide the ideal amount of brightness, focus, and visibility for optimal performance. Learn more about how the face can impact light output in this light pipe design guide.

Our team can assist you in determining the right light pipe face for your device, including running light simulations.

VCC offers three board mount options to choose from. Because board mount light pipes often have more design restrictions, here are the pros and cons of each type:

Board-mount right angle:

Benefits: standard product, fast lead time, low production cost

Design restriction: you have to design your device/equipment around the specs of the light pipe

Board-mount linear:

Benefits: standard product, fast lead time, low cost

Design restrictions: light pipe can be a maximum of 1.20” in length, and the minimum height between the LED and front panel can present design challenges

Board-mount flexible:

Benefits: extensive selection of standard products, short lead times, enhanced flexibility, electrical isolation.

Design restriction: flexible light pipes cost more per unit than rigid options

When flexible light pipes are board mounted, they receive the added protection of electrical isolation. This isolation can help prevent damage due to vandalism of the exterior of the device, as well as protection from electrostatic discharge (ESD).

Even static can cause ESD and damage electronic devices, so VCC’s FLXR series light pipe can help prolong the life of the device and prevent dangerous surges in electricity.

Check out our smart parking meter case study

Exact specifications may depend on the design of the device, but as a general guideline, the wider the viewing angle, the more light loss. With a narrow viewing angle, such as 160 degrees, more light is directed into the light pipe and less is lost.

Contact VCC for assistance in determining the ideal specs for your design needs.

To accommodate the design of your device, light pipes can be mounted on either the control panel or the PC board.

Panel-mount light pipes are attached directly to the indicator panel, which can deliver increased efficiencies during production if using press-fit light pipes.

VCC provides a wide range of IP and NEMA-rated products for a variety of applications. Many of our products meet NEMA 4 and IP56 standards. However, even higher moisture protection of NEMA 6 and IP67 can be attained on specific products, or by using additional seals or threaded construction.

Download the light pipe brochure or refer to the product data sheet for more information.

A Fresnel lens diffuses the light, making it ideal for environments where ambient light or a more high-contrast, concentrated illumination is required.

Fresnel lenses are best suited for applications where wide viewing angles a daytime visibility are crucial for effective status indication

A series of concentric grooves bend parallel light rays to one focal point for high-contrast, no glare illumination.

For high-vibration applications, an additional grommet or spring retainer can be used to help secure the light pipe to the panel.

For light pipes (LPC and LPCR) that are .250” to .500” in length, use the Grommet retainer. For LPC and LPCR light pipes that are between .500” to 1.000”, use a Spring Retainer to secure the light pipe to the panel.

Board-mount light pipes are available in rigid and flexible options.

With board-mount light pipes, the design may be limited, as everything must be designed around the light pipe and spacing of the board. However, if you can achieve your desired results with a standard board mount light pipe, you can take advantage of low cost sand short lead times.

Contact VCC to determine which mounting option would be ideal for your design. Of course, a custom light pipe could also be the right solution for you.

Adjusting the length of a light pipe by anyone other than the manufacturer is not recommended.

Cutting the light pipe will change the optical characteristics, making it less effective in the device it was specified for. Any bubbles or scratches in the light pipe will ruin transference, as light will not be directed where it was intended.

VCC’s team can customize light pipe length for you in ways that do not yield less-than-optimal optical characteristics.

Light pipes can be overmolded, however it is not recommended.

Any overmolding of the light pipes can distort the transmission of the light due to total internal reflection (TIR), resulting in performance that doesn’t measure up to the design specifications or quality standards.

If additional resins are necessary, double molding is recommended. This process, also called two-shot molding, bonds two separate materials together in a single mold, making it ideal for complex parts in high volumes.

When creating custom light pipes, VCC uses stereolithography (SLA) for 3D printing prototypes used to validate the design. Any polishing is the last step in validating the design — the prototype light pipes are already chemical and mechanical polished by VCC before they are sent to the client.

The final components are produced with the proper surface finishes outlined by VCC in the industrial specification.

Because rigid light pipes are made of plastic or polycarbonate acrylic, there are certain length limits based on design features. Length limits for rigid light pipes:

Press fit: 1.20” max

Custom design: 1.5” max.

Standard design: up to 2” with several shorter versions available

Because flexible light pipes are made of fiber optic materials, there is no limitation on the length of a flexible light pipe. However, the desired light and optical properties of the light pipe may dictate the appropriate size.

Contact VCC’s team to discuss your specific design goals.

Yes, VCC manufactures our light pipes at our production facility in Tijuana to maximize efficiencies close to our San Diego headquarters. Both VCC facilities are registered to ISO 9001 2015 Quality Management System standards. This means our systems governing the design, development, manufacturing, delivery and internal customer service processes have been verified by third-party audits.

One of the advantages of using flexible light pipes (hence the name) is the ability to bend and navigate the light pipe around other components on the PCB or device without sacrificing your desired light output. You can transmit light from the LED on your PCB to the HMI, even when the board is crowded with multiple indicators.

Our extensive line of flexible light pipe products delivers unmatched selection and convenience in making sure your light goes the distance.

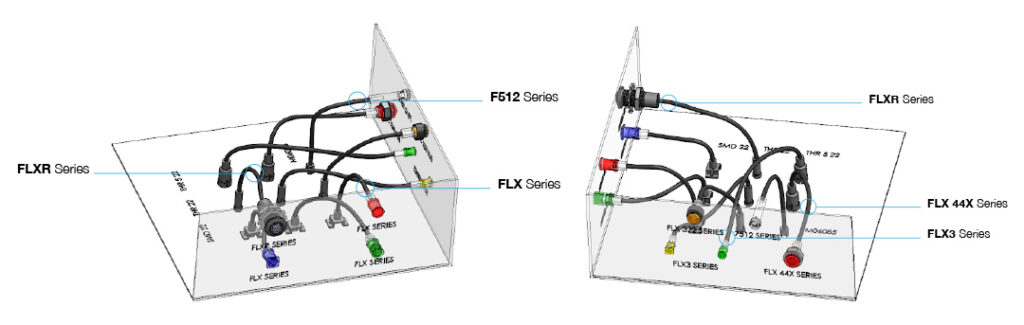

Standard light pipes include:

FLX3 Series

FLX Series

7512F Series

FLX_322 Series (IP56)

FLX 44X Series

FLXR Series

View the entire lineup in our light pipe brochure.

Need a custom flexible light pipe? Work with our team of engineers and designers to determine the appropriate solution for your application.

Whenever your design doesn’t include light from a straight line (like a rigid light pipe), additional decisions must be made to determine the length and placement of your flexible light pipe, including:

- Where the light source is located

- How far the light needs to travel

- Mounting and construction of the device

- Additional design and space constraints

VCC’s experienced team can help you determine the exact product to meet your optical specifications.

Yes, when a device has multiple light sources, light pipes are recommended over panel mount indicators (PMIs) in most cases. Because PMIs typically have a higher cost per indicator, using several PMIs on a device would drive up the cost.

In most cases, we would recommend light pipes for a design with multiple indicators. Contact the VCC design team for help comparing options for your device.

Light pipes that include the appropriate level of moisture protection for their applications can be used outdoors.

VCC has a wide array of rigid and flexible light pipes that are moisture-sealed and ideal for harsh environments like the great outdoors.

In addition to moisture protection, the FLXR Series litepipe also features ESD protection and is resistant to shock and vibration. It also has a low-profile design that helps protect against vandalism.

Yes, VCC offers a full suite of custom light pipe design and testing services. Using the latest light modeling software, our team can run light simulations, such as ray tracing to track the path of light through the light pipe to deliver the ideal solution.

We can also use a 3D printer to prototype the light pipe and further test prior to tooling the custom solution, ensuring the ideal viewing angle and lighting properties are achieved.

Yes, viewing angle is crucial when using a light pipe.

The narrower the angle of the LED, the more light can be transmitted through the light pipe to the indicator. VCC recommends a viewing angle of 160 degrees or less.

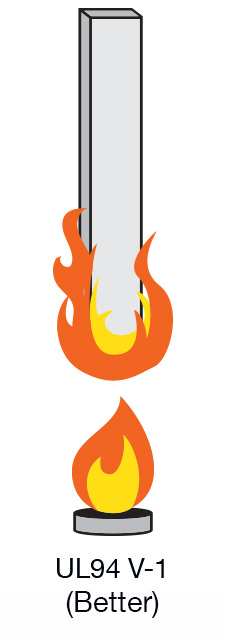

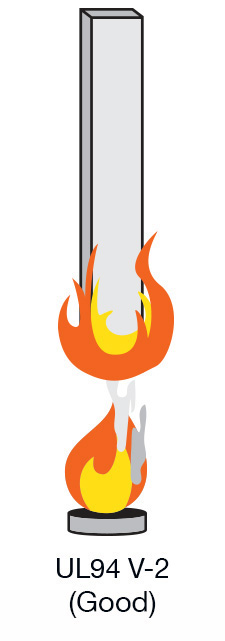

The UL rating will vary by light pipe material, as VCC offers both acrylic and polycarbonate options.

Most of our light pipes have received a UL94V-0 rating, the best in the industry. The product data sheet will always list the specific UL rating.

In some instances, manufacturers and designers are required to obtain the UL Yellow Card for Plastics to demonstrate the components have passed rigorous safety and performance testing by Underwriters Laboratories and received a UL Recognized Component Mark.

If you need to obtain the UL Yellow Card for Plastics, contact the VCC team and we will provide it for you.

The MOQ for a custom VCC light pipe will depend on the order volume and customization required for the design. In some cases where minimal retooling of our equipment would be required, smaller custom orders can be filled.

Please contact our experienced team to discuss your specific design needs. Our experts can work with you to design, tool and manufacture exactly what you had in mind.

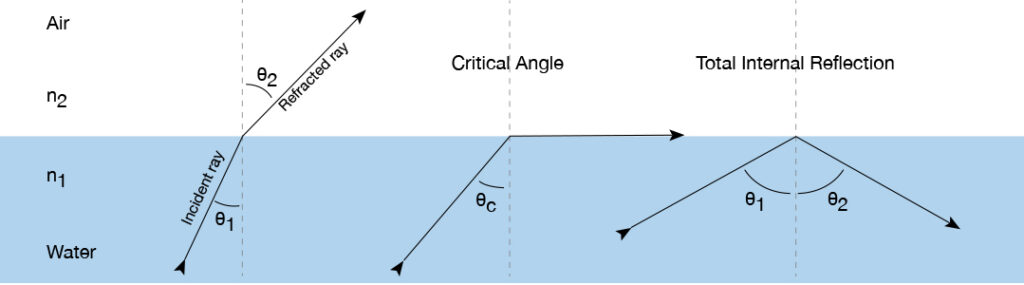

Light refraction occurs when a ray of light appears to break when it shines through different surfaces. This change in the direction of the light wave happens when the wave passes from one surface to another or the surface itself has a gradual change.

For example, in a vacuum, the refraction rate is 1.00. But in water, it’s 1.33, meaning the speed at which the light travels is slightly slower in air than in a vacuum.

Other refraction rates that matter in light pipe design include:

Air = 1.0003

Acrylic = ~ 1.49

On the opposite end of the spectrum, there’s reflection. When light shines through a surface, it’s refracted. When light bounces off of a surface and shines elsewhere, that is the reflection.

Total internal reflection is the complete reflection of light from surrounding surfaces back into the medium. The phenomenon occurs if the angle of incidence is greater than a certain limiting angle, called the critical angle.

TIR is essential when calculating the light needed for a right-angle light pipe where the light must bend around a corner while reducing light loss.

For more on how refraction, reflection, and other factors impact light pipe performance, explore our Light Pipe Design Guide.

Light loss occurs when some of the light intended to travel through the light pipe escapes before reaching its destination — the exit point where the end-user sees the light.

Also known as light bleeding, this scenario can be reduced by using a narrow viewing angle LED at the input instead of a wide viewing angle LED. The diagram below illustrates how closing the gap between the light pipe and the LED through a smaller viewing angle can minimize light loss.

There is no such thing as zero light loss from a light pipe, but there are several ways to help reduce light loss. To dig deeper into light loss and all things light pipe, we created an informative Light Pipe Design Guide.

Light pipes come in all shapes and sizes. And if they aren’t optimized, you can see hot spots and other imperfections that can add up to inefficiency.

Effective light pipe design delivers a better experience for end-users by providing:

- Uniform illumination

- Maximum visibility

Dog valet

Smart parking meter

Robotic vacuum

Smart headphones

Medical alert system

Drone

Two-way communicator

Label maker

Less-than-ideal light pipe design is easy to see:

- Hot spots

- Uneven illumination

Bad light pipe examples:

Pet tracking system

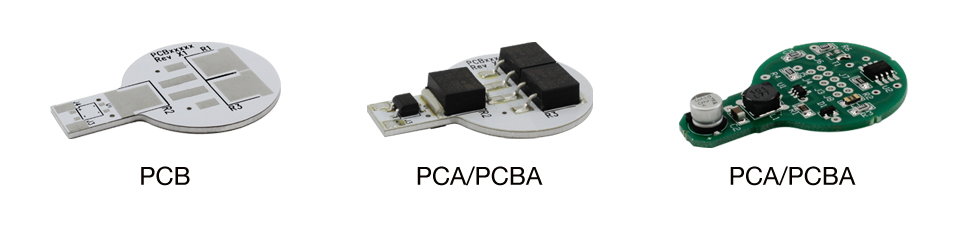

While PCB, PCA and PCBA are used interchangeably in the industry, here’s what they really mean:

- PCB – printed circuit board. It’s the “naked” board without the electronic components.

- PCA – printed circuit assembly. A populated board with all the components.

- PCBA – printed circuit board assembly. It’s the same thing as a PCA — a board with all the components included.

PCB is the most commonly used acronym when referring to the circuit board populated with all the components (which is the PCA or PCBA).

A printed circuit board (PCB) is a board used to hold a chip or other electronic components. To accommodate various design needs, a PCB can be a single layer or consist of multiple layers. PCBs can also be single-sided or double-sided in design.

Several PCBs can be linked in a single device, using either flexible or rigid connectors.

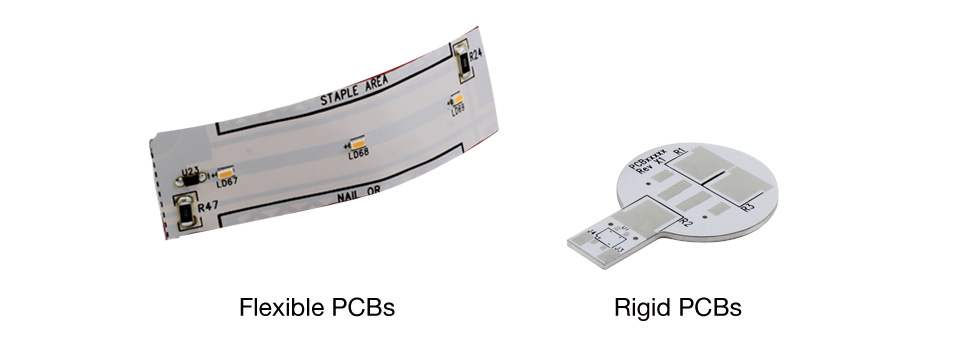

The answer is both. PCBs can be either flexible or rigid in design.

- Rigid PCBs are designed not to move, and typically cost less to manufacture than flexible PCBs.

- Flexible PCBs, or flex boards, are designed to move, twist and fold into the desired configuration, and can eliminate the need for connectors and other components, which can reduce overall production costs.

VCC can work with you to determine the ideal solution for your design — one that maximizes efficiencies.

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

PCBs are typically made of multiple layers, including RF4 material substrate (such as fiberglass) for insulation, and copper to conduct electric current.

Creating a PCB is a multi-step process that includes:

#1 Designing the PCB – advanced software is used to determine the size, dimensions and number of layers needed for the PCB.

#2 Printing the PCB design – a specialized printer called a plotter printer is used to print the design, which is made up of multiple layers for the conductive and non-conductive areas. The print becomes the foundation of the substrate, which holds the components of the structure includes copper on both sides of the layer.

#3 Printing the copper for the interior layers – the design of the PCB is printed to a laminate that includes a film designed to react with ultraviolet light to properly align the board and the layout of the electrical components.

#4 Getting rid of the extra copper – because the design has been cooked and processed with ultraviolet lights, certain areas are hardened and the copper is bonded to the board. The next step is to use a chemical solution to remove the unnecessary copper from the board.

#5 Inspection and layer alignment – once the extra copper is removed, the design must be scrutinized to ensure all the layer and drill holes align properly. A machine drills a pin through the layers to keep them aligned. Then another machine tests the board for errors.

#6 Laminating the PCB layers – once the board passes inspection, an epoxy resin layer is applied to laminate the board. Another layer of substrate is applied, then layers of substrate resin and copper foil are applied and pressed together.

#7 Drilling holes – a computer-guided drill is used to drill holes through the substrate and inner panels at the appropriate places for the design. Once drilling is completed, any copper left over is removed.

#8 PCB plating – an additional copper layer is added to the board, followed by a thin tin guard to protect the outer layer of copper from being etched off. From there, the PCB receives a solder mask, silkscreen with critical information and placed with a solderable finish.

PCBs provide many benefits for designers and manufacturers of electronic devices. Printed circuit boards:

- Save space – They save space in the device by allowing all interconnections to take place on the board itself, without the need for current to be carried through multiple wires.

- Allow for easy installation and repair – troubleshooting and diagnostic testing are easy to conduct to address on the PCB, as all components are clearly labeled.

- Provide quick assembly – compared to conventional methods of connecting circuits, PCBs save time in assembly.

- Stay in place – because all the electronic components are soldered to a single board, they do not shift when moved.

- Efficient to mass produce – PCBs can be produced in large quantities at a more cost-effective rate than other power methods of component connectivity.

- Provide reliable power – because connections are made with the copper tracks on the board, they are less likely to come loose.

VCC can design and create both SMT and through-hole components for assembly. Design considerations:

- Through-hole components are typically larger, and can only be soldered to one side of the PCB.

- SMT components are smaller in size and ideal for tiny PCBs where space is limited.

Let our experienced team help you optimize the device of your next design.

Our team offers a comprehensive suite of PCB services, including:

- Custom design services to optimize output and indication

- Rapid prototyping made even faster and cost-effective with our in-house 3D printer

- Sample runs so you can easily test concepts and tweak designs

- Mass production to efficiently accommodate large quantities

If you have additional questions, or are ready to discuss your next project, we’re here to help.

Contact us today for your PCB, PCA and PCBA needs.

With an entire building dedicated to SMT fabrication, we have four pick and place lines and three ovens to support those lines. We also have the ability to expand or increase capacity with additional shifts to meet your needs.

We adhere to the highest standards for quality and safety. VCC has the following certifications:

Learn more about VCC’s regulatory compliance here.

Our team can read Gerber files, as well as AutoCAD, Multisim, and ViewMate.

Have specific questions about submitting files? Contact your Regional Sales Manager or contact our support team.

For turnkey projects, we’ll need the following:

- Bill of materials (BOM)

- Component placement list (CPL)

- All relevant CAD and ODB++ data (later in the process)

We have 25,000 square feet in total manufacturing space and a 5,000-square-foot facility dedicated to PCBA production.

We need approved Gerber files, schematics, and a PCB layout to move forward with productionYour Regional Sales Manager can assist you with obtaining a quote or placing an order. Here’s a list of our Regional Sales Managers and their contact information:

Mario Rossetti

Business Development Manager

(480) 395-8658

Karla Solis

Sales Development Representative

(858) 386-5666 ext. 5793

VCC pursues all applicable UL certifications for our products, and we offer several products certified with UL and CSA, including OEM lamps.

Underwriters Laboratories (UL) grants multiple certifications, including:

- UL Listed or UL Listed to Canadian safety standards

- VCC is certified for PCBA by UL file E520330

Yes, VCC does offer assemblies that comply with the European Union’s Restriction of Hazardous Substances (RoHS) Directive.

We also meet several other regulatory standards. See the full list here.

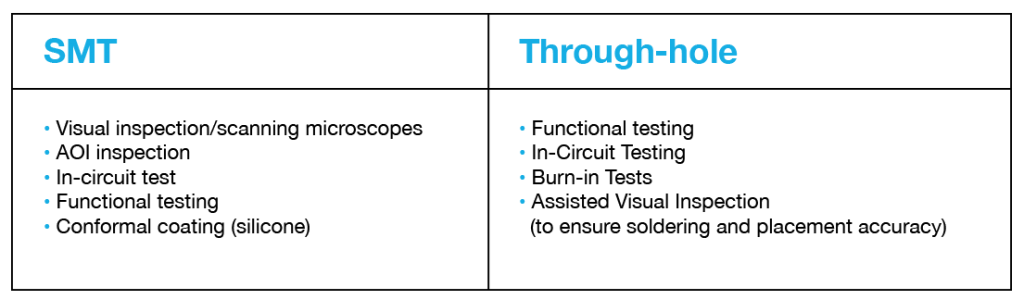

Yes, VCC offers a comprehensive list of testing and inspection services for both SMT and through-hole assemblies.

Learn more about our facility and specifications here.

VCC has obtained the following IPC electronics industry standards for PCB assembly:

IPC-610 – standard for PCB production

IPC-620 – practices and requirements for cables, wire, and harness assembly manufacturing

Our PCB assemblies and other products are manufactured just across the border in Tijuana, Mexico. By keeping production nearshore, we deliver a range of cost and time-saving benefits to our customers, including:

- Cost savings

- Faster delivery

- Tariff-free transactions

- Reduced supply chain risk

- Responsive customer service

We’ll ship your products FCA from our headquarters in San Diego, so you won’t have to worry about costs associated with importing. Learn more about how nearshore manufacturing can streamline your PCBA production here.

If you have additional questions or are ready to discuss your next project, we’re here to help.

Contact us today for your PCB, PCA, and PCBA needs.

The answer depends – is it a simple design, is it a complex design? There are a few questions that if know will help VCC provide an accurate decision:

- Do you already have the 3D CAD file

- Have you selected the needed LED(s)

- Are there multiple color LED or one single color

- Is there an illumination intensity output known (lumens/MCD)

- Is the final application to be viewed in a daytime or nighttime environment

- What is the desired distance you wish to view/see the light

- What is the desired viewing angle

- Would VCC handle the production of the finished part, or only help with the design.

- What is the estimated annual usage (EAU)

- Is there a tooling budget set

- What is the timeline for prototypes and/or production

Although there are other details that would need to be discussed, these are some of the initial pieces of information that help us determine not only the time to delivery, but also the cost of the project

The types materials used in the indicator, including the LEDs, determine operating and storage temperatures of the unit.

The typical operating range for VCC products is -13F (-25C) to 176F (80C) but can be affected by the design and work environment.

Sample operating temp: 13F (-25C) to 176F (80C)

Sample storage temp: -22F (-30C) to 212F (100C)

Since they have an impact on the overall life of the device, both operating and storage temperature should be considered when specifying an LED or indicator.

VCC provides a data sheet for each product to help designers and manufacturers find the right solution for their specific application.

Underwriters Laboratories (UL), is a global safety company that tests products based on its stringent safety standards. UL ratings and listings are used to determine the safety standard of finished electrical devices, as well as the components that go into them. From the housing to the lens, bezel and type of wire used in VCC components, we obtain UL Recognized Component Marks to demonstrate compliance with UL’s standards.

In addition to UL marks, our products can include CE, cULus and CSA listings. These designations are given by organizations outside the U.S. to demonstrate compliance with safety guidelines.

The various rating types are as follows:

| Logo | Label or listing | Description |

|---|---|---|

|

UL Listed | UL Listing means the finished product meets all UL requirements based on its nationally recognized standards for safety. |

|

UL Recognized Component | For components, such as LEDs, housing, lenses and light pipes where UL Recognized Mark means the manufacturer has demonstrated the ability to produce components that will go into a finished product that will earn a UL Listing. |

|

CE | The CE mark indicates compliance with requirements of the applicable European laws or directives. |

|

cULus / cURus | For product marked as: cULus listed or cURus recognized, it means the product, device or component, has been tested under Canadian and U.S. standards. |

|

CSA | The CSA mark indicates the product has been certified to meet standards of the Canadian Standard Association. |

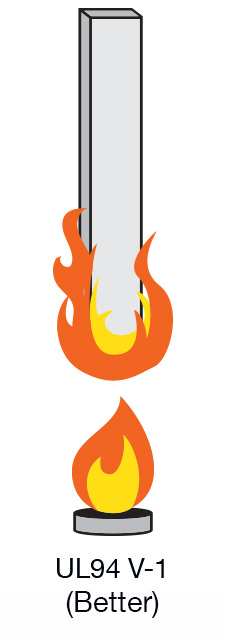

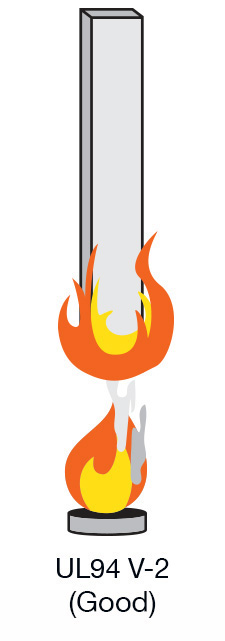

One of the most important standards for our products is the UL94V-0 flammability standard. The test evaluates both the burning and afterglow times of the test specimen, then rates them as follows:

| Rating | Description |

|---|---|

| V-0 Vertical Burn | Burning stops within 10 seconds after two applications of ten seconds each of a flame to a test bar. NO flaming drips are allowed. |

| V-1 Vertical Burn | Burning stops within 60 seconds after two applications of ten seconds each of a flame to a test bar. NO flaming drips are allowed. |

| V-2 Vertical Burn | Burning stops within 60 seconds after two applications of ten seconds each of a flame to a test bar. Flaming drips ARE allowed |

PMIs can connect to the power source in two ways:

Wire leads – the indicator is connected to the power source by wires that must be long enough to run from the panel to the PCB. Standard size for wire leads will vary by product and can be customized to accommodate device design. Refer to the VCC product page on the website or the data sheet for wire lead information.

Quick-connect tabs – metal tabs are used to connect the indicator to the power source without the need for wires, thus enhancing design flexibility. Depending on the product, there are standard sizes for the quick-connect tabs that should be accommodated in the panel design. Refer to the product data sheet for more information.

| Pros | Cons | |

|---|---|---|

| Wire Terminals | • More cost-efficient per unit • Wire length can be customized |

• Less design flexibility • Slightly slower production and assembly than quick-connect tabs |

| Quick connect tabs | • Greater flexibility in production and assembly • Can run parallel production since no additional assembly or wires are required |

• Higher upfront cost than wire terminals |

To accommodate OEMs and customers in a wide range of industries, VCC offers several mounting styles. Our experienced team can help you determine which solution will help optimize your design. Our mounting styles include:

Snap-fit: With snap-fit mounting, the PMI fits inside the panel mounting hole and snaps into place with a metal connector. The PMI fits securely in the panel without the use of additional hardware, making it easy to install. Snap-fit mounting can save significant time and money during assembly, allowing multiple products to run at once without the additional handwork required for wire leads.

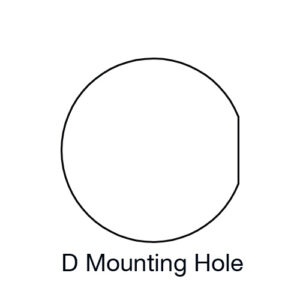

Snap–fit with “D” mounting: the PMI fits into a D-shaped mounting hole on the panel to help prevent any rotation of the indicator. Indicators using snap-fit with D mounting are easy to install and stay secure in place. Snap-fit with “D” mounting is ideal for high-vibration applications, such as industrial equipment.

Press Fit: with press fit mounting, the indicator is secured when the LED housing and the panel are pressed together create a secure seal due to friction. The tightness of the seal will be determined by the interference allowance.

Threaded housing with hex nut: securing a threaded housing on the PMI with a hex nut enables both quick and easy assembly and installation. This mounting configuration helps reduce shock from impact or vibration, which extends the life and overall reliability of the machine.

Speed nut: a speed nut is a piece of additional hardware that acts as a lock washer and nut in securing the indicator into the panel. While this mounting style does require the speed nut accessory, it provides a very secure hold that doesn’t shake loose with vibration but can easily be removed or loosened if needed.

How is the speed nut used?

The push-on speed nut accessory is a self-locking piece that is simple to apply and provides maximum holding power at minimal unit cost. The speed nut replaces threaded nut, lock washer or spanner washer combinations and is easily assembled by running the PMI through it and attaching it to the panel.

Best of all, this accessory will not shake loose from high vibration during operation.

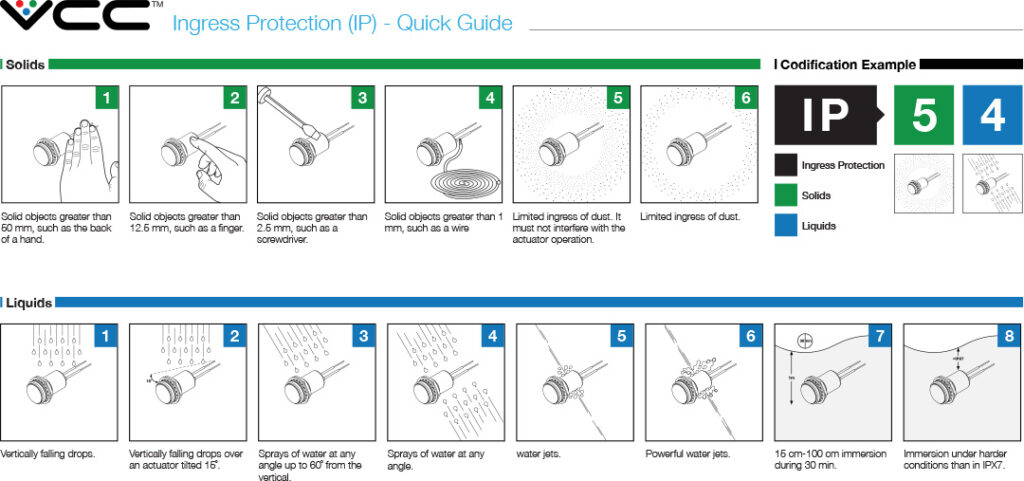

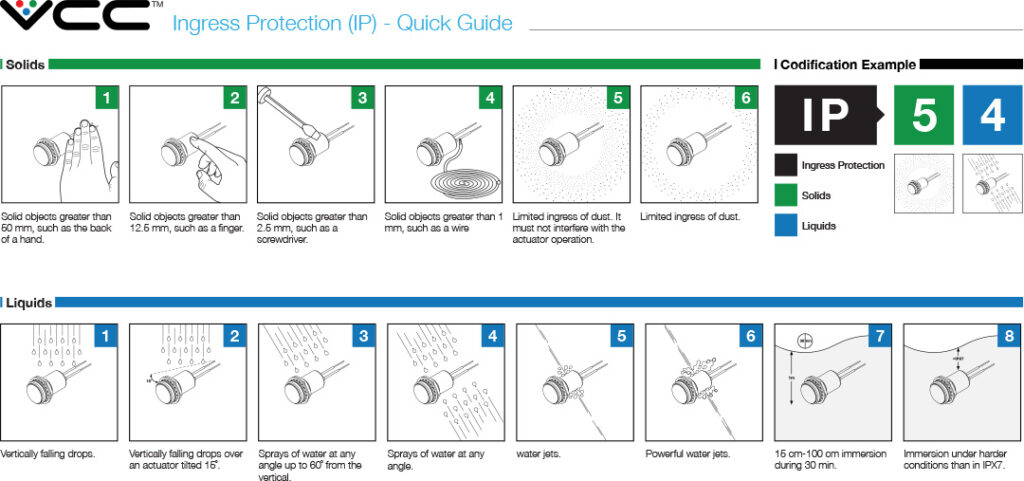

To indicate protection levels, we use IP ratings. IP ratings, known as Ingress Protection or International Protection ratings are numerical scores used to communicate the levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies such as dirt and water. These ratings are defined to the international standard of EN 60529 ((British BS EN 60529:1992, European IEC 60509:1989).

Example IP Rating: IP65

In this example, the first digit represents protection from solids and the second digit represents protection from liquid. If one of the digits is replaced by an “x” then the device is not rated for that specification.

Here’s a quick reference guide of the two and what they mean:

Solids – degree of protection from foreign bodies

Liquids – protection level from various forms of moisture (drips, sprays, jets and immersion).

VCC’s Typical IP Ratings

The IP Ratings of our extensive product portfolio will vary, but most of our solutions fall within the following ratings suitable for a wide range of applications:

- IP65 – dust tight and protected against water projected from a nozzle.

- IP67 – dust tight and protected against complete, strong water jets and waves.

Additional PMI protection is available

VCC also offers additional protection from dust and moisture with the option to include an O-ring gasket on the PMI. This additional piece of hardware provides an added layer of protection, acting as a seal between the indicator and the panel, which helps maximize the life expectancy of the equipment.

Please refer to your product data sheet for availability.

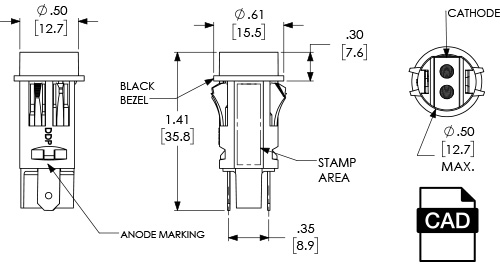

Some PMIs include a bezel in their construction. A bezel is a neck, or “sleeve” that encases the LED. It can be used to protect the indicator from moisture and dust, or to enhance the design aesthetic. For example, a black bezel can provide a greater contrast with the LED itself, allowing greater visibility when the LED is on.

A bezel can be constructed of many types of material, including plastic or stainless steel. All of VCC’s products that include a bezel are made of durable materials and quality construction.

Depending on the design, a bezel can be recessed, prominent or flush with the panel mount indicator.

To learn about the bezel specs of a specific product, please refer to that product’s data sheet. You can also learn more by contacting the VCC team.

It’s very important for an engineer or designer to ensure the PMI’s voltage will remain within the recommended operating voltage.

On average, the voltage tolerance for VCC products is ±2VAC/DC. However, each product is different. For voltage tolerance information, refer to the product data sheet or contact VCC.

Typically, a lamp lifespan for each type of lighting technology is as follows:

- LED: 50,000 to 100,000 hours

- Neon: 25,000 hours

- Incandescent: 1,000 hours to 1,500 hours

Things that can negatively impact bulb life:

- Operating voltage

- Operating temperature

- Exposure to voltage spikes

- Mechanical shocks and vibrations

- Frequency of being turned on and off

Note: the type of lamp used in the panel mount indicator will impact the overall operating lifetime of the PMI.

Because LEDs last an average of 133 times longer than incandescent bulbs, they dramatically reduce maintenance and operating costs over the life of the device. That’s why VCC recommends LEDs for most applications, delivering greater value to our customers.

Our team can modify our standard components or start from scratch to design a solution that meets our clients’ mechanical, electrical, communication and aesthetic needs. We have extensive expertise in design, prototyping, tooling, manufacturing and assembly. VCC is committed to adding value by providing the most effective and efficient solution for our customers.

Our PMIs can be customized in a variety of ways to meet or exceed design requirements, including:

Customized Cable Harness:

- Wire length, wire gauge and termination

- Including additional terminals or connectors

Electrical & Optical Options:

- LED brightness

- LED viewing angle

- Bi-color and tri-color indicators

- Lens colors

- Bezel finishes – plastic and stainless steel

- Bezel styles – recessed, flush or prominent

- Bezel color – white, black or silver (depends on finish)

Typically, a panel mount indicator should be used when there are only a few indicators on the panel, and light pipes should be used when there are several indicators on a single panel that are tightly spaced.

Because the more indicators you have on a single HMI, the more expensive it would be, light pipes are more efficient for devices and applications where a high number of indicators would be needed on the same device.

For example, a portable welding device would use a PMI, while an electronic device charging station with 20 or more individual status indicators would use light pipes to maximize efficiency.

The VCC team is here to help you determine the best approach for your design needs.

Depending on the materials, application, size, features and customization, the typical cost range is $1 to $6 per unit. However, PMIs with extensive customization and features can cost as much as $20 or more per unit. Customization can be made to:

- Wire length

- Terminals

- Brightness

- Viewing angle

- Bi-color option

- Tri-color option

- Lens color

- Finish

Our team will always work with you to find solutions that are cost-effective and meet your needs.

Yes, VCC’s ruggedized indicators can be used outdoors, but only when conditions align with the product’s IP rating. Environmental factors such as temperature and moisture can affect equipment performance when PMIs without the appropriate IP rating are used outdoors. Please refer to each individual product’s IP rating and operating information on the product data sheet.

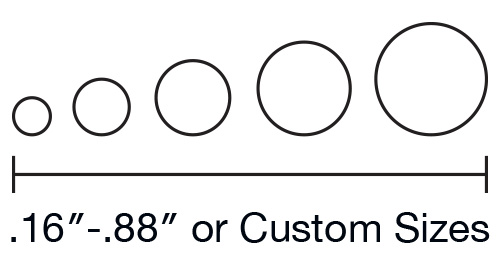

Every design is unique. So, VCC offers a wide range of mounting hole sizes to help customers design an attractive and effective user interface. Our indicator mounting holes range from .16” (3.98mm) to .88” (22mm), with the ability to create custom sizes to accommodate design specifications if the appropriate minimum order quantity is met. Please refer to the product data sheet or product page of the website for mounting hole specifications.

The MOQ for a custom VCC indicator will depend on the order volume and customization required for the design. Typically, a custom PMI would require an order of at least 3,000 units. However, there are instances where the MOQ could be much less. Please contact our experienced team to discuss your specific design needs.

Our solutions-oriented experts can work with you to design, tool and manufacture exactly what you had in mind.

If using multiple indicators on the PMI, external resistors provide greater control in lowering the brightness of the LED.

Be sure to check your product’s datasheet for technical specs and requirements.

Nearshoring manufacturing, or nearshoring, is defined as outsourcing specific business processes or operations to companies to another country to reduce production and operating costs.

When the manufacturer is nearshore, it is located in a neighboring country — one that typically shares a border with the nation where the hiring company is headquartered.

Nearshoring provides companies with several benefits, such as:

- Streamlined supply chain

- Shorter lead times

- Eliminated communication delays due to time differences

- Reduced transportation and shipping costs, including tariffs

Often used interchangeably, offshoring and outsourcing aren’t quite the same things.

Offshoring is relocating certain business operations to another country in efforts to save on labor or other costs.

Outsourcing is transferring business activities to partners outside of the company — whether they are located in the same country or on the other side of the globe.

Nearshoring is outsourcing business processes to countries that are in close proximity to the company’s headquarters or manufacturing operation. In many cases, both countries will share a border, which makes transporting products faster and more convenient.

For example, our components are manufactured in Mexico, and often shipped to our customer’s facility located in the same country. We help shorten the distance to the customer by both implementing nearshore manufacturing.

Efficiencies can also be attained when the nearshoring partner can create and assemble multiple electronic components, like PCB sub-assemblies under one roof — without having to ship the product to Supplier A, B, or C. Streamlining the supply chain can speed up development and delivery times while saving on shipping and other costs.

Similar to nearshoring, nearsourcing is strategically positioning certain operations in close proximity to where the final product will be sold or used. For example, a U.S. cable conglomerate could establish a call center in Canada instead of Asia, keeping service reps closer to its customers.

Insourcing and reshoring are similar in that they both involve the company itself doing the manufacturing.

Reshoring is the process of moving a company’s overseas/offshore manufacturing back to the same country where the organization is headquartered. An easy way to remember it is this: reshoring = returning home for manufacturing operations.

Similarly, insourcing is keeping manufacturing or other processes in-house. This doesn’t mean my specific location, just within the walls of the company instead of with an external partner or vendor.

In the past, outsourcing operations to save on labor and other costs became a balancing act to find the right trade skills and talent when looking at nearshore manufacturing partners.

However, Mexico has made significant investments in its education and training incentives to help the workforce remain competitive in an ever-changing, technology-driven marketplace.

The country has over 2,500 higher education institutions, some of which are partnering with companies in other countries for research and design projects. With more than 3.8 million students enrolled in higher education in 2018, México is solidifying its role as a manufacturing hub with ample highly skilled workers.

With more than 110,000 engineers graduating every year, it’s no surprise high-tech companies turn to the country for the production of everything from automotive and electronics to medical devices.

When companies use offshore partners to handle specific functions, such as production or assembly of goods, they do so hoping to take advantage of cheaper labor costs. However, depending on where the products are made, they may incur steep tariffs when being shipped back to the U.S. for distribution and sale.

For example, the recent trade war between the U.S. and China has caused a sharp rise in tariffs on goods being imported from the Asian country. Currently, the tariffs are at 19.1% — a rate more than 6 times higher than pre-trade war operations.

Alternatively, when companies use manufacturers with friendlier trade agreements in place with the United States, they can eliminate these steep swings in operation costs that must either be absorbed or passed to customers.

VCC’s manufacturing operations are located in México, allowing our customers to take advantage of tariff-free trade and reduced production costs. To learn more about the benefits of nearshoring, read “5 Ways to Reduce Supply Chain Risk with Nearshoring.”

When you hear the term turnkey, you probably think of something that is ready to go immediately. However, in the electronic component landscape, turnkey PCB assembly is where your PCB manufacturer handles everything associated with the production of your assembly, including:

- Design & PCB layout

- BOM and supply procurement

- PCB manufacturing

- Schematic design

- Prototyping and testing

- Automated and manual assembly

- Additional connectors (add-on)

VCC’s turnkey PCB assembly services deliver a more streamlined and cost-effective production process, as well as shorter lead and delivery times. Learn more about our custom PCB capabilities here, or check out the “PCB Assembly Design Guide.”

- Automated Solder Paste Application

- Automated Pick and Place Machines

- 8-Zone SMT Solder Reflow Ovens

- Automated Optical Inspection (AOI)

- Through-Hole Assembly

- Wave and Soldering Machine

- Conformal Coating Equipment

- X-RAY PCBA Equipment Capabilities

- Leaded and Lead-Free Assembly

- Cable Assembly Services

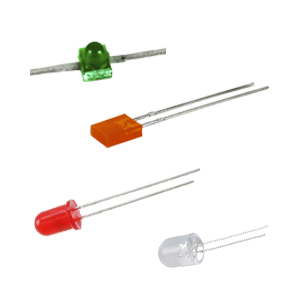

VCC offers a diverse range of discrete LEDs, including SMD, through-hole, bi-color, ultra-bright, and infrared models, all designed for PCB integration and backlighting.

-

SMD LEDs are compact, ideal for automated assembly and space-constrained designs.

-

Through-hole LEDs are better for mechanical strength, hand soldering, and prototyping

Bi-color LEDs have two chips in a single package. They can produce two distinct colors based on the direction of current flow or by controlling each lead separately.

VCC offers LEDs with narrow to wide viewing angles, typically ranging from 30° to 120°, depending on the lens and LED type.

Brightness varies by model and color. VCC offers standard, high-brightness, and ultra-bright LEDs, measured in millicandelas (mcd).

Absolutely. VCC’s discrete LEDs are widely used for membrane switch backlighting, custom light pipes, and status indication in HMI systems.

VCC offers options in Red, Green, Yellow, Blue, Orange, and White across multiple LED families.

Most LEDs operate at a forward voltage of 1.8V to 3.3V, depending on the color, and typically require 5mA to 30mA forward current.

Yes—select VCC LEDs are designed to withstand high operating temperatures, vibration, and harsh environments, suitable for industrial, automotive, and medical use.

All standard LED products are entirely RoHS and REACH compliant, and many are also UL recognized for safety and reliability.

Typically, five or more layers, including overlay, circuit, spacer, dome retainer, and adhesives.

Backlighting options include top-fire or side-fire LEDs, light guides, and EL (electroluminescent) lamps.

Top-fire for direct light and side-fire LEDs paired with light guide films for even distribution.

Low profile, sealed for cleanliness, cost-effective, and highly customizable for HMI applications.

Typical substrates include PET or ITO, with conductive inks made of copper, silver, or graphite.

Through metal domes, embossed overlays, or tactile pads within the circuit layer.

Yes, graphic overlays, lighting, connectors, and circuitry can all be tailored to your application

Extremely durable LEDs can last 50,000+ hours, depending on application and environment.

Many are designed for use in moisture or dust-prone settings, often meeting IP65 or higher standards.

Typically, pressure-sensitive adhesive (PSA) or integrated mechanical housing designs.

-

Momentary switches return to their default position when released (e.g., push-to-start).

-

Latching switches stay in position until actuated again (e.g., on/off toggle).

VCC switches are designed to handle high inrush currents and support a wide range of voltage loads, typically from 125V to 250V AC and up to 20A, depending on the model.

Some VCC toggle, rocker, and pushbutton switches are available with integrated LED illumination for visual feedback or night visibility.

This varies by switch type:

-

Toggle switches have a firm click.

-

Pushbuttons offer light to moderate tactile feedback.

-

Rockers provide smooth actuation.

Please take a look at the individual datasheets for exact specs.

Select models feature IP65 or IP68 sealing, ensuring dust and moisture resistance, as well as vibration-proof construction, making them ideal for outdoor or rugged industrial use.

Configurations include SPST, SPDT, depending on the control logic and circuit complexity required.

Yes, most switches are UL recognized, CSA certified, and RoHS/REACH compliant, ensuring quality and adherence to relevant regulations.