Choosing the Best Material for My Design

Proper Optoelectronic design requires attention to every detail. Luckily, designers have many illuminated component options to provide more flexibility in how status indicators work on the back end. These are also known as light pipes.

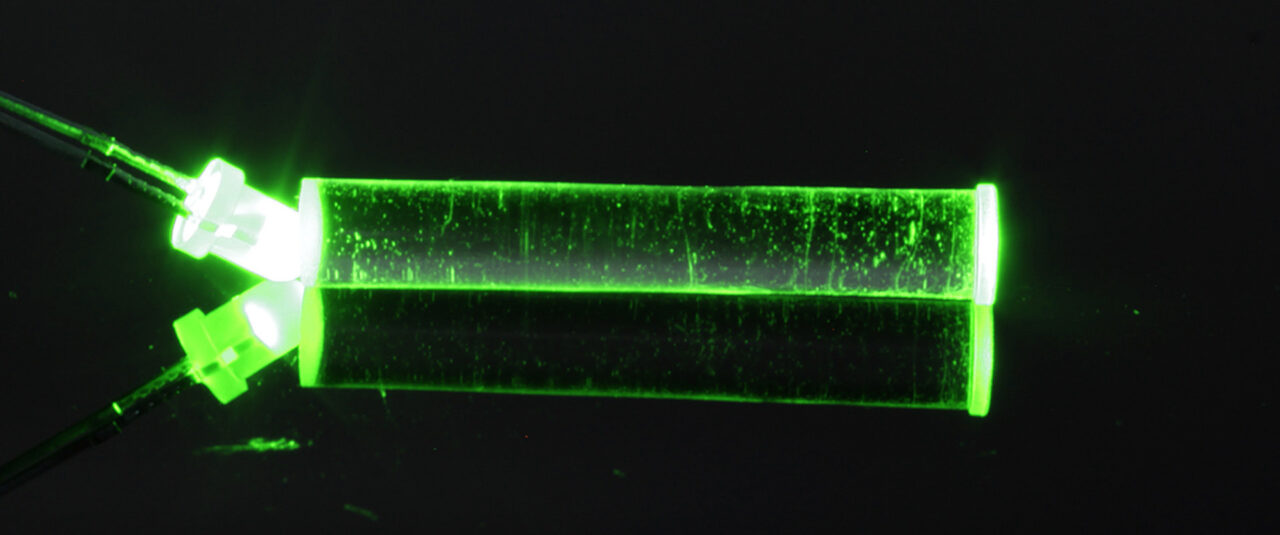

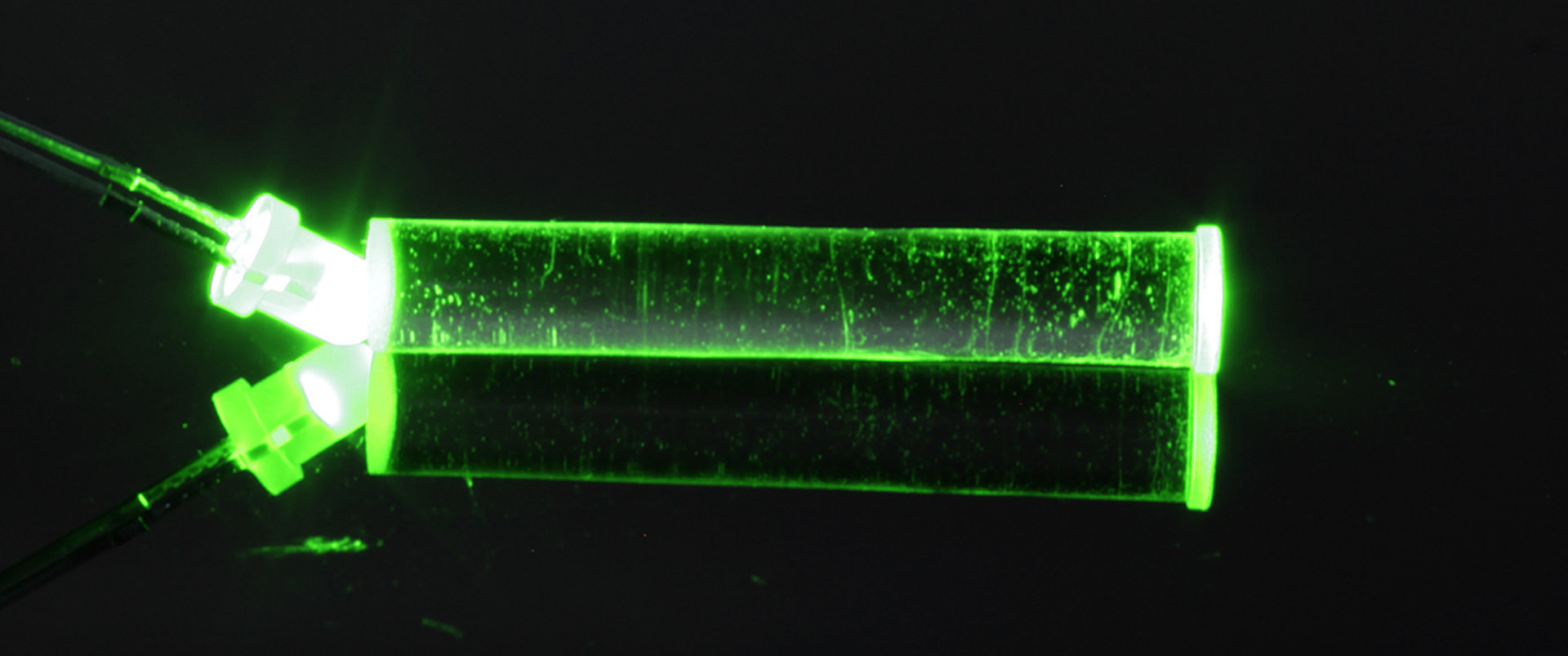

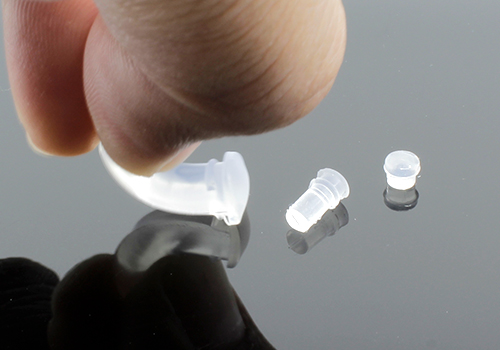

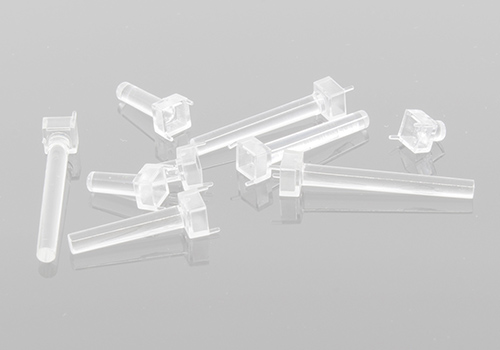

Light pipes are clear rods typically made of plastic or chemical materials, although some can also be made of glass. These passive optical components transmit light from point A to point B, freeing up some design constraints by eliminating the need for an LED to be mounted directly on the panel.

They also help diffuse the light where hot spots would otherwise be noticeable and could even impact the safe operation of a device.

When determining which materials to use for the light pipe, it’s a good idea to start at the end — the application.

Will the light pipe be used in an in-dash electronics system? Or a consumer device?

Will the indicator be mission-critical for industrial equipment? Or potentially life-saving in the operating room?

Optical Engineering Considerations

Once designers fully understand the requirements of the application, they can identify the optical properties and light pipe characteristics needed to find the best fit, including:

- Softness or hardness for molding

- Flammability requirements

- Outdoor usage

- Vibration and moisture needs

- Operating temperature range

- Board, indicator, and indicator orientation being used

- Any ultraviolet (UV) or infrared radiation (IR) requirements

There is no one-size-fits-all solution for all applications, so it is a good thing there are many high performing light pipe materials to choose from.

LED Optics: Light Pipe Materials with Winning Attributes

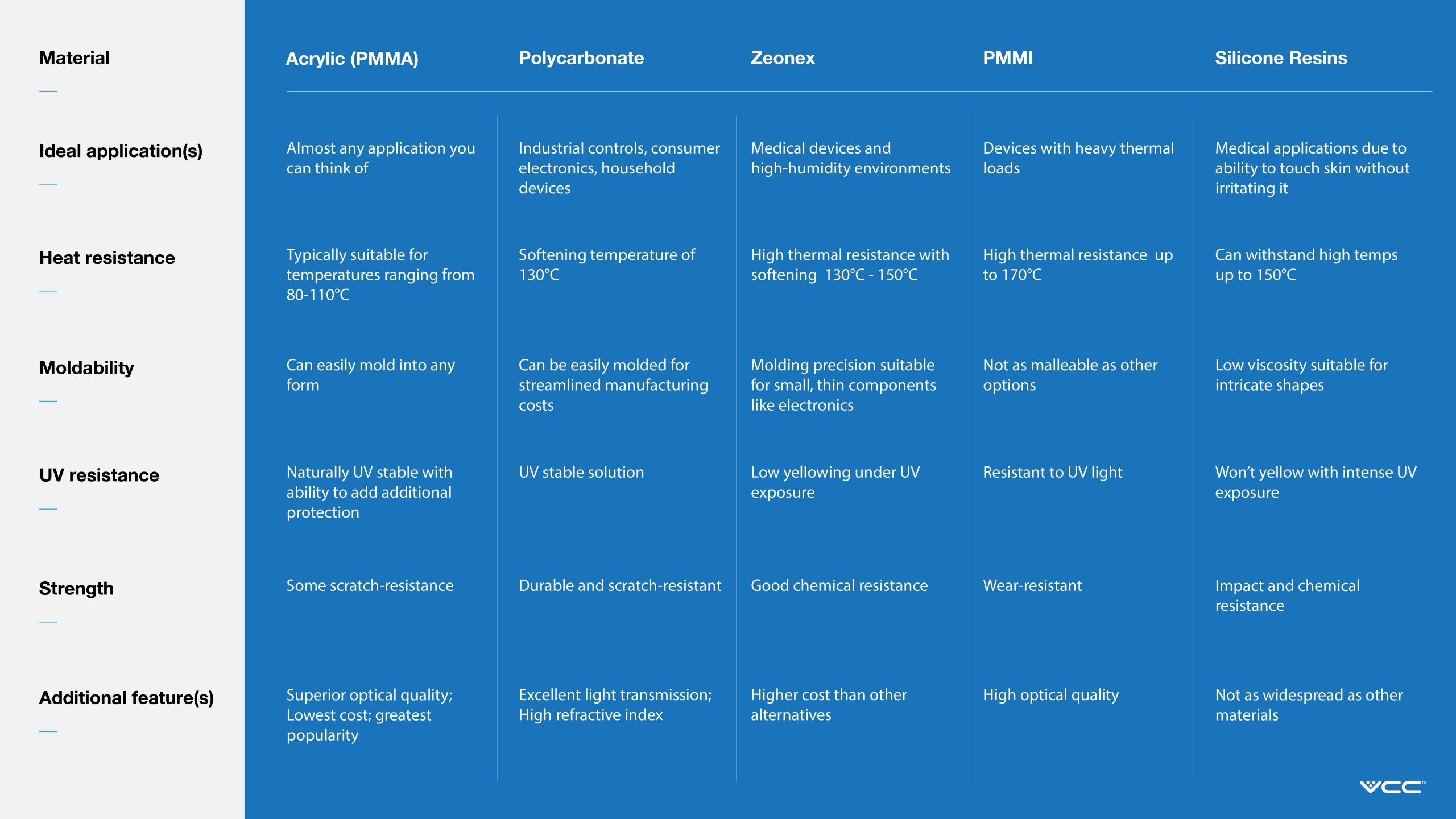

In addition to the rare instances when using glass is appropriate, there are typically five materials used for light pipes in LED illumination design, each with their own strengths and weaknesses.

Choosing the Best Material for My Design

While VCC has the capabilities to deliver light pipes in all five options, most of our standard products are either acrylic or polycarbonate. We believe these two are the materials of choice for a range of illumination design needs, thanks to their performance and versatility.

Let’s take a closer look at these two options:

Acrylic (PMMA)

Optical-grade acrylic can provide the flexibility, performance and affordability to get the illumination job done. Typically made of PMMA (polymethylmethacrylate), acrylic light pipes will be superior due to their:

- High light transmittance – PMMA allows 92% of light to pass through it, which is more than glass or other plastics.

- UV stability – because PMMA also has a high resistance to UV’s damaging rays, it’s suitable for outdoor applications or other use cases with exposure to UV light. Colors stay intact, too — even during abuse from ultraviolet light.

- Cost effectiveness – compared to polycarbonate solutions, acrylic light pipes are slightly less expensive, making them the preferred option for panels with multiple indicators.

Polycarbonate (PC)

Similar to acrylic light pipes, polycarbonate versions are great at transmitting light, easily molded and strong. Here’s how PC light pipes shine:

- High impact resistance – compared to acrylic, polycarbonate is more durable.

- Increased heat resistance – ideal for high-temp operating conditions.

- Non-flammable – for applications where UL94 compliance is a concern, polycarbonate brings superior ignition resistance.

- Increased strength over acrylic – polycarbonate is more than ten times stronger than acrylic, providing durability for harsh working environments.

- Stability in UV environment – similar to acrylic, PC light pipes are UV stable

More applications for light pipes

High Pressure Washer

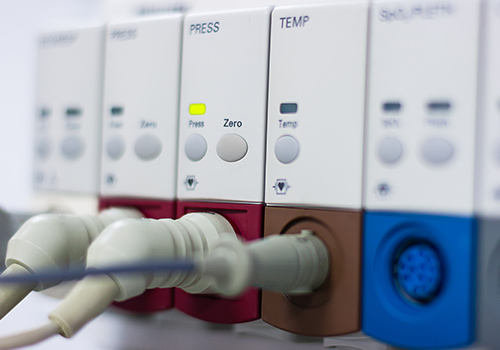

Medical Device

Infrared Thermometer

Common questions to address when selecting a light pipe

Will the light pipe be used in an in-dash electronics system? Or a consumer device?

Both acrylic and polycarbonate are great at diffusing light, however, polycarbonate does a better job at it. Other design requirements and light pipe characteristics can help determine which material is best.

Are light pipes available in different colors?

While most light pipes are clear or white, designers can specify colored light pipes to be used with color or white/clear LEDs. Typical light pipe colors are red, yellow, blue and orange. Both acrylic and polycarbonate can be used to create light pipes with color.

Which plastic materials can be used for outdoor devices?

While both acrylic and polycarbonate are great at withstanding UV exposure, acrylic is naturally UV stable and also available in grades with enhanced UV stability. Of course, operating temperatures will also be a determining factor.

Of course, the material used is only one aspect of a light pipe. Additional considerations:

- Surface

- Color

- Shape

- Length

- Coatings

- Device footprint

Optical engineering can be complicated, but when the right questions are asked early-on, the end result and the budget are better off.

Because each device is unique, sometimes a standard solution simply won’t do. If you need to tweak a standard light pipe or start from scratch to meet your exact specifications, building your own is easier than you think.

Optical light pipe manufacturing can help you find the right size, shape, durability, and costs for your device.

LED & illumination design go hand-in-hand. And light pipes are a cost-effective solution for optimizing the user experience in a range of applications. Whether you need help selecting a thermoplastic for your injection-molded part or know exactly which 3D printing material to use for full production, VCC has the expertise to assist you at every stage of the design process for LED and illuminated components.

Need help designing the light pipe or lens to your exact needs?

Contact our team of experts