Case Study

Custom LED Indicator for Portable MIG Welder

Durable Application Characteristics

MIG welding (GMAW – Gas Metal Arc Welding) is the most common process used in home shops, small businesses, manufacturing and metal fabrication applications. The portable, all-in-one MIG welding machine offers a compact and lightweight solution for auto restoring, DIY home hobbyists, farm/ranch, metal art/sculptures, manufacturing and more.

The portable MIG welder has a breakthrough technology that sets your welder to the proper parameters. The Auto-Set feature automatically provides the right settings to weld mild steel while tapped voltage control allows the flexibility to manually set your own parameters.

Auto-Set eliminates guesswork and saves time on setup. When using .030-inch wire, turn the wire speed control fully counter clockwise to select Auto-Set mode. The importance of wires in connecting the components and ensuring proper functionality cannot be overstated. The Auto-Set light indicates mode is activated. Then select material thickness using the voltage/material thickness control. Auto-Set is available for welding 22-gauge through 12-gauge mild steel, and works with .030 solid wire and C25 shielding gas (75% argon, 25% CO2).

The portable MIG welder also has an over temperature light on the control panel to ensure proper and safe use of the machine.

Design Considerations for LED Indicators

When designing LED indicators, several factors must be considered to ensure optimal performance and durability. The type of LED used, the color and intensity of the light, and the device’s overall design all play a crucial role in determining the effectiveness of the indicator. For instance, the choice of color can significantly impact the visibility of the indicator, with green being a popular option due to its high visibility in various environments. Additionally, the design should prioritize ease of install, with features such as simple wiring and minimal hardware requirements. Durable materials and construction are also essential to ensure the indicator can withstand harsh conditions and maintain its performance over time. By carefully considering these design elements, manufacturers can create LED indicators that meet the needs of various applications and provide reliable status indication.

Solution & Design for Easy Install

VCC delivered a custom design for the MIG welder with 2-LED and 3-LED assemblies connected to a terminal. The wires used to connect the LED assemblies to the terminal ensure proper functionality and ease of installation, even in challenging environments.

The MIG welder uses blue L59 Series LED panel mount indicators with hi dome lens and a low profile black nylon housing for the Auto-Set indication.

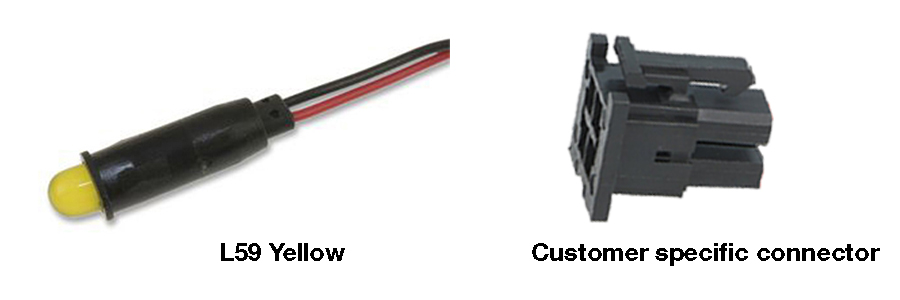

In addition, the MIG welder uses yellow L59 Series for the over temperature light indication.

With a diameter of 0.250”, the L59 Series offers a viewing angle of 60 degrees. The indicator has a diffused lens to increase light output across the entire lens, which is particularly important for daytime use.

With a diameter of 0.250”, the L59 Series offers a viewing angle of 60 degrees. The indicator has a diffused lens to increase light output across the entire lens, which is particularly important for daytime use.

The series provides illumination for applications that require consistent identification and communication through light, and achieves full brightness in microseconds.

Benefits of LED Indicator Lights

LED indicator lights offer numerous benefits, making them an ideal choice for a wide range of applications. One of the primary advantages of LED indicator lights is their energy efficiency, which can lead to significant cost savings and reduced environmental impact. They are also highly durable and require minimal maintenance, reducing the need for frequent replacements and repairs. Furthermore, LED indicator lights are available in a variety of colors, allowing users to select the most suitable option for their specific needs. The ease of use and install of LED indicator lights also makes them an attractive choice, as they can be easily integrated into existing systems and devices. With their high visibility, long lifespan, and low power consumption, LED indicator lights are an excellent option for applications where reliable status indication is critical.

Safety Regulations

Safety regulations play a vital role in the design and implementation of LED indicators. Manufacturers must ensure that their products comply with relevant safety standards and regulations, such as those related to electrical safety, environmental impact, and occupational health. For example, LED indicators used in hazardous environments must be designed to withstand extreme temperatures, vibrations, and other harsh conditions. Additionally, safety regulations may dictate specific requirements for the color, intensity, and visibility of LED indicators, particularly in applications where they are used to signal potential hazards or dangers. By adhering to these safety regulations, manufacturers can ensure that their LED indicators are safe, reliable, and effective in providing critical status information.

L59 Series LED Indicator Lights

The L59 Series offers a wide operating voltage range from 2 to 24 volts DC and is available with wire leads or straight leads. Customization options for wires, such as length and type, are available to ensure the versatility and functionality of the LED indicators in various installations.

The snapfit LED simplifies installation and maintenance.

Value-added Service

The MIG welding machine is ideal for anyone who is looking for a compact, lightweight MIG welder that’s easy to use, accommodating nearly every metal type and thickness used by a car builder, and it has arc characteristics rated as best in class.

The low-profile L59 Series LED panel mount indicators offers high brightness and clear indication for the Auto-Set function and over temperature warning. These lightweight assemblies ensure proper communication through light with the welding operator.

Value-added Service

As a value-add, VCC was able to add the customer-specified terminals and connectors at a lower cost than if it were done in-house.

VCC understands the importance of visual communications and brings value to your design challenge. VCC’s Mission, Vision, & Values becomes an extension of your design team and can provide technical advice and value to your design challenge.

Conclusion and Future Developments

In conclusion, LED indicators are a crucial component in various applications, providing reliable and efficient status indication. With their numerous benefits, including energy efficiency, durability, and ease of use, LED indicators are an ideal choice for a wide range of industries and applications. As technology continues to evolve, we can expect to see further advancements in LED indicator design, materials, and functionality. Future developments may include the integration of new features, such as wireless connectivity, advanced sensor technologies, and enhanced durability. By staying at the forefront of these developments and prioritizing safety, manufacturers can continue to create innovative LED indicator solutions that meet the needs of an ever-changing world. Whether you’re looking to select the perfect LED indicator for your cart or designing a new device that requires a reliable status indication, LED indicators are sure to play a vital role in making your project a success.