Pizza Heater Cabinet

Industry

Foodservice

Retail

Hospitality

Technology

Expertise

Design Consulting

Design & Engineering Service

Multiple Lighting Technologies

Products/Services

1050 Series PMI

PCL22 Series PMI

High-voltage PMI

IP65-Rated Product

Standard Product

Nearshore Manufacturing

Application Characteristics

In the food industry, consumers have high expectations when it comes to flavor and consistency. One bad experience can result in not only the loss of a customer, but also a negative online review that could impact future sales.

And pizza heating cabinets are the perfect vehicle for providing a seamless self-serve experience — but only if the quality is there. Customers can order and pay online or through an app, then receive notification when their pie is ready. They can then go straight to the pizza heater to pick up their order — no line, no waiting, and no human interaction. The key to success in this self-service model is maintaining the highest levels of quality and freshness.

Food warmers like pizza heating cabinets must perform a few key functions:

Keep the food fresh, hot, and safe

Maintaining the right temperature and relative humidity required for freshness and food safety should be top priority

Maintain constant, real-time communication

With the pizza restaurant employee on one side, and the consumer on the other, both sides need to constantly illustrate operation status

Be simple to understand

Operation shouldn’t require any special training or instruction for employees or customers

Application Requirements

When designing food equipment like warming cabinets, several considerations should be taken into account:

01. Cabinet height and placement

Must be designed in ways that are easily reachable and visible for consumers

02. Versatility

Which types of foods will need to be kept warm? What moisture conditions will need to be implemented?

03. Volume and dimensions

How many items will be heated/housed at once?

04. Control panel / user interface

The more intuitive the better for all users and customers

05. Accessibility

The heater should open from two sides — one for employees to place the pizza in from behind the counter, one for consumers to pick it up.

Caleb Hwang

Mechanical Engineer, VCC

Solution/Approach

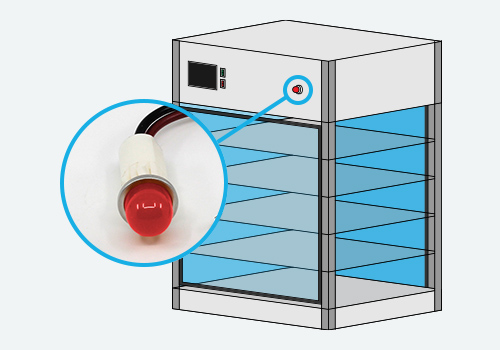

1050 Series

The 1050 Series Neon Panel Mount Indicator with wire leads was used to provide bright, consistent illumination in 125V. This red neon indicator easily snaps into a 12.7mm hole and supports quick and easy assembly during production. Available in 125V or 250V, as well as a range of lens options.

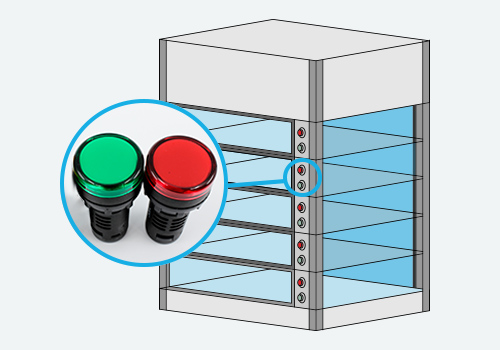

PCL22 Series

There’s no product line more perfect for keeping pizzas at the perfect temperature than VCC’s PCL22 Series. VCC recently launched the PCL22 Series, a 22mm pilot light solution that enhances visual communication even further with a large pilot light that offers uniform illumination. The PCL22 LEDs are simple to install, eliminate hot spots, and can be seen from a wide viewing angle, even at great distances.

The PCL22 Series was used for both red and green panel-mount indicators in 24V. These high-performance LEDs are watertight to IP65, helping make them the ideal pilot light solution for pizza warming cabinets, and include advanced light diffusion technology to eliminate hot spots. Single color options include red, green, white, blue, and yellow. A bi-color red/green option is also available for enhanced design versatility.

Omar Lara

Sr. Process Engineer, VCC

Results & Benefits

Through collaboration with the client, VCC’s design team combined neon and LEDs to provide a solution that ultimately delivers:

- Increased visibility for effective communication with users and customers

- Intuitive interface for hassle-free customer pick-up

- Consistently high-quality product delivery, which will lead to repeat business

- Higher order volume and increased efficiency without sacrificing quality

- Improved freshness of pizza due to constant temperature and humidity levels

- Reduced human error, which leads to a better customer experience

- Streamlined production time and costs due to using existing off-the-shelf products

- Supply chain simplification and reliability through nearshore manufacturing

Value-Added Services

By recommending standard components that met the client’s exact specifications, VCC helped the manufacturer save on production lead time and production costs. No prototyping was required to validate the design, meaning the pizza cabinet went to market faster.

Whether it’s pasta, pizza, or another beloved food group, VCC has the experience, quality and insights to ensure food safety and reliability are built into the design.

IoT is everywhere, but there’s still room for HMI improvement. VCC provides designs and components that enhance the user experience.