Application Characteristics

VCC is aware that the auto industry is trending toward a more technology-enabled manufacturing process, and is making it a priority to keep up with the latest technology.

VCC was approached with a specific set of requirements for what the customer would require in the outfitting of their new machines with visual indication.

The tools needed to be able to survive rugged conditions and communicate status to workers in a particular way, with a wide enough viewing angle that would not hinder the work done on the floor.

Application Requirements

The auto welding machine and auto drilling machine, specifically the Laser Spot Welding & Drilling Machine is an essential tool for any modern auto manufacturer, and our customer needed to outfit their new machines with the proper equipment to uphold their high safety standards.

Developments in lasers and beam machine technology are expanding the range of metals that may be welded successfully, and are substantially more cost effective than other options on the market. Spot welding, seam welding and drilling can all be made more efficient through its use, and many of the options can be retrofitted into existing systems.

With new technology comes new requirements for ensuring safety in the workplace; in recent years the industry as a whole has strived to manufacture safer vehicles in safer work conditions, and our customers contacted us when they needed help achieving these goals.

Solution / Approach

Working closely with the customer, VCC took pains to not only understand the use of the specific device, but also deliver a product that would excel the customer’s expectations.

Temporal pulse shaping, aluminum welding, high brightness applications, battery manufacturing, solder mask stencil manufacturing and polymer welding were all actions the customer would be using the Fiber Laser for, and the team at VCC first began by researching the specifications of the machine in question.

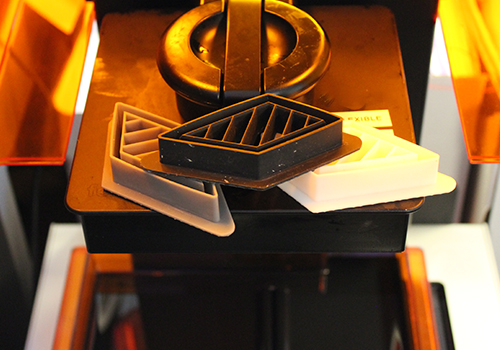

With this information in hand,the CNX714FV all-in-one indicator with connector was recommended to be a great fit for the harsh,industrial environment of auto manufacturing.

The design is built around a14mm ruggedized LED indicator, which is key for communication to the worker and using communication of light for safety purposes.

The indicator is mounted in a robust chassis and has a wide viewing angle, and is built around a moisture-sealed lock that is resistant to shock and vibration.

CNX714FV

Developed for harsh environments, the 14mm CNX714 FV Series LED indicator is resistant to shock and vibration, and is moisture sealed for outdoor applications. This LED indicator upholds the customer's high safety and performance standards. The IP67 rated panel mount indicators have a long operational life.

The series provides illumination for applications that require consistent identification and communication through light, and achieves full brightness in microseconds. VCC's panel mount indicators, represented by the CNX714FV, are intended for integrating light-based communication into the chassis of industrial automation equipment like laser welding and drilling machines.

Results & Benefits

VCC’s illuminated components allow the industrial operators to make better, more informed decisions.

Through communication with light via the illuminated communicator control panel, operators have better control of systems, ensuring proper performance and increasing safety.

What features make LED panel mount indicators suitable for auto welding machines?

The features that make LED panel mount indicators suitable for use on auto welding machines, according to the case study, primarily revolve around their durability, visibility, and reliability in a harsh industrial setting.

The key features include:

- Rugged and Robust Design

- Resistance to Shock and Vibration

- Moisture Sealing (IP67 Rated)

- Wide Viewing Angle

- Instantaneous Status Communication

- Long Operational Life

Value-Added Services

As a value-add, VCC was able to add the customer-specified terminals and connectors at a lower cost than if it were done in-house.

VCC understands the importance of visual communications and brings value to your design challenge. Clear and reliable visual communication is the key function that the illuminated components provide on the auto manufacturing floor, allowing industrial operators to make better, more informed decisions instantaneously.

VCC takes the time to fully understand new technologies, and with that knowledge in hand our sales team makes sure our customers are given the best possible customer service and product fit.

VCC becomes an extension of your design team and can provide technical advice to ensure your indicators meet mechanical, electrical and optical requirements.

Case Study Media