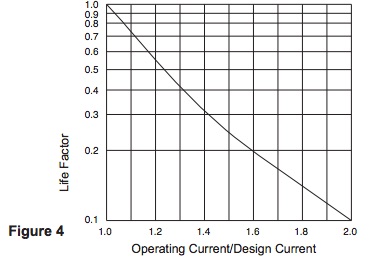

Lamp Construction

Basic Principle of Lamp Operation

The basic construction of neon lamps is shown in figure 1. The bulb is made of glass sealed in two areas, the pip and the pinch. In the pinch area, the leads protrude through one end of a glass tube and the glass is heated and pinched about the leads. This holds them in position and forms a hermetic seal. The leads are made from a special material known as dumet which is a low resistance material consisting of a copper sheath around a nickel iron core constructed so that its expansion coefficient is the same as that of the glass used for the bulb. Butt welded to the lead wires are nickel electrodes of larger diameter.

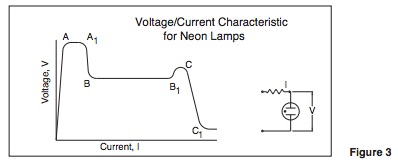

Neon lamps have the voltage/current relationship shown in Figure 3, which determines their operation. As the applied voltage is increased there is virtually no current flow until the striking voltage is reached at point A. The current then increases to a value A which is largely determined by the impedance of the external circuit, and the voltage across the neon lamp reduces to a lower value B, known as the maintaining voltage. Further increasing the supply voltage (or reducing the external impedance) increases the lamp current with little change to the maintaining voltage until point B is reached.

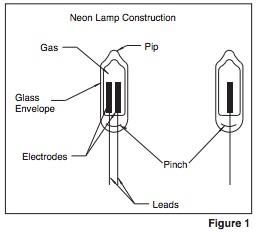

These electrodes are coated with a special emissive material prior to being sealed into the glass bulb.This emissive coating has a lower work function than the base material andcauses the neon lamp to have a lower striking voltage than would otherwise be the case. The sealed unit is evacuated and an inert gas is introduced via the pip prior to tipping off. The neon lamp is commonly used without a base in “wire-terminal” form, and is available with or without a resistor. Versions are available mounted on a metal or plastic base for replaceable use in a corresponding lampholder or fitting. Lamps mounted on bases are available without a resistor or with a resistor incorporated inside the base for direct operation from main voltage supplies. These lamps consist of a T-2 neon lamp with a series resistor welded on, mounted in the metal base with a plastic top cap as shown in Figure 2.

Dark Effect

If the lamp is used in total darkness, some ignition delay can occur unless a tube which contains a small amount of radioactive material is used. Operation in total darkness is normally only encountered in situations where the neon lamp is being used as a circuit component (i.e., its electrical characteristics are of prime importance, its indicating property being of secondary or no importance). In this case a cold cathode diode should be specified which is “dark effect” reduced.

Lamp Characteristics:

The main characteristics of neon lamps are detailed as follows. In general, these characteristics are not tightly controlled, as the prime function of the device is to emit light to act as an indicator. If a tube having a more controlled electrical specification is required for use as a circuit component, a cold cathode diode should be used.

Light Output:

Neon lamps are available from Chicago Miniature Lamp in two light output ranges (standard and high brightness). The standard brightness types have a light output of approximately .06 lumens per mA, and the high brightness types emit approximately .15 lumens per mA. The light output of neon lamps is mainly in the yellow and red regions of the spectrum between 580 and 750 nanometers with a band in the infrared between 820 and 880 nanometers.

Striking Voltage:

The voltage at which the neon lamp ignites is usually between 45 and 65V a.c. for standard brightness types and between 70 and 95V a.c. for high brightness types. This is sometimes called the breakdown or ignition voltage.

Maintaining Voltage:

The voltage across the lamp after it has ignited. This voltage is a function of the lamp current and is usually quoted at the design current. Nominal values are 60V for standard brightness and 75V for high brightness lamps.

Extinction Voltage:

The voltage at which the lamp extinguishes if the supply voltage is reduced. It is normally a few volts below the maintaining voltage.

Design Current:

The current at which the lamp has been designed to operate. It will be determined by the supply voltage and the value of series resistance. Operation at lower currents can result in the glow discharge becoming unstable (i.e., flickering) and operation at higher currents can severely reduce the useful life of the lamp. It is therefore important to use only the recommended value of series resistance.

Operating Temperature:

Neon lamps can be used up to a maximum temperature of 160°C, but for optimum life it is recommended that wherever possible the operating temperature should be within the range -50°C to +90°C. However, it should be noted that carbon film resistors which are recommended for use in series with neon lamps are normally derated, for maximum power dissipation, at temperatures above 70°C. Therefore, at higher temperatures other types of resistor, such as metal oxide, may be more suitable and resistor manufacturers’ data should be consulted.

Leakage Resistance:

This is not a specified parameter, but in practice values in excess of 10 ohms will apply to wire terminal lamps. Measurements should always be taken in total darkness as photoemission from the electrodes under ambient illumination will result in false, low resistance readings. The voltage at which leakage resistance is measured should be at least 10V below the minimum striking voltage of the lamp.

Then the maintaining voltage increases with current to a point C when the neon lamp discharge changes from a glow to an arc and the voltage across the lamp drops to a few volts at C . Neon lamps should be operated in the range B to B which is called the “negative glow” region. B to C is the “abnormal glow” region and from C beyond is the “arc” region. A neon lamp operates in the following manner: when the applied voltage is in excess of the striking voltage, electrons are emitted from the surface of the negative electrode (cathode) and, accelerated by the electric field, collide with atoms of gas. One of two reactions occur: 1. The traversing electron can collide with an atom of gas and elevate one of its valence electrons to a higher energy state. At some time after being elevated, the electron will return to a lower energy state and a photon of light will be emitted.

The wavelength of the light output is determined by the difference in energy levels, which will be dependent upon the type of gas used. The total light output from a neon lamp is the result of millions of such occurrences at a given instant. 2. The atom can have an electron knocked off, in which case the atom becomes a positively charged ion. This ion is attracted by the negative electrode (cathode) and accelerated towards it. On colliding with the cathode, the ion causes material to be removed, a phenomenon known as sputtering. The emissive coating on the electrodes of neon lamps is removed by ionic bombardment so that eventually the base metal is exposed and the striking voltage of the lamp increased. When the lamp is operated from an a.c. supply, each electrode is alternately positive (anode) and negative (cathode) and material is sputtered from them during alternate half cycles.

However, when the lamp is operated from a d.c. supply, one electrode is constantly the cathode and material is removed from it during the entire time that the neon lamp is operating. Consequently, the effects of sputtering become apparent earlier during d.c. operation and the lamp life expectancy is about 60% of that when operated from an a.c. supply. For reliable operation, neon lamps require some free charged particles to be present in the tube to initiate the glow discharge when an operating voltage is applied. These charged particles can be created by photoemission from the emissive surface of the electrodes, so that if the lamp is used in normal light no ignition problems should be encountered.

Life Expectancy

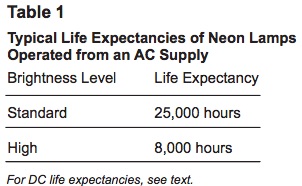

The end of life of a neon lamp is usually a catastrophic failure, but is an arbitrary condition when the light output has reduced to an unacceptably low level. During the life of a neon lamp, material is sputtered from the electrodes and some of this adheres to the wall of the glass bulb which has the effect of reducing the light output. The process is a gradual one, and not until many thousands of hours of normal operation will the blackening be such that the light output has fallen below an acceptable level and the lamp be at the end of its useful life. Because the minimum acceptable light output value will depend upon the application, it is difficult to quote precise lifetimes, but values for 50% reduction of initial light output levels are given in Table 1.

Since in most applications the lamp will not be operating all of the time, the actual life of the lamp in the equipment will be considerably longer than the quoted life. It should also be noted that because the blackening initially occurs around the sides of the glass bulb, a longer lifetime is usually achieved if the lamp is end-viewed. The life expectancies quoted in Table1 apply to neon lamps operated from an a.c. supply. As explained earlier in these notes, when the lamps are operated from a d.c. supply, lifetimes are approximately 60% of these values. In order to obtain the maximum lifetime it is recommended that ±5% carbon film series resistors be used. Variations in supply voltage will also affect the life of the lamp due to the resultant change in operating current.

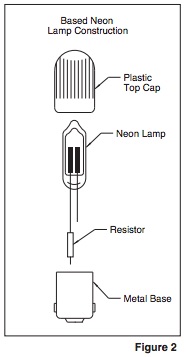

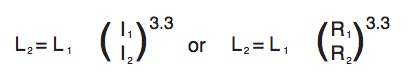

The relationship between operating current and life can be expressed as a 3.3 power law, where L is the life expectancy at the design current I with the recommended series resistance R , and L is the life expectancy at current I with the series resistance R .. This relationship, which is shown graphically in Figure 4, is approximate and should only be used as a guide to the effect on life for changes in operating current. It should not be used to estimate lifetimes when the current is more than twice the design current, since other factors, such as heating of the electrodes, will cause an even greater reduction in lifetime. Operation at currents lower than the design current will theoretically result in increased life expectancy. However, this is not recommended as the discharge may become unstable initially or after a period of low current operation.

Green Fluorescent Lamps

The basic difference between green fluorescent and neon lamps is that the gas discharge (glow) in the neon lamp is directly viewed through the transparent glass bulb. In the case of the green lamp, the inside of the glass bulb is treated with a fluorescent coating which emits a green light when the gas is ionized.