What Happens When a Key Supplier Disappears Into Thin Air?

Before coronavirus was ever an issue, one traffic signal infrastructure supplier found itself in a similar predicament many OEMs recently found themselves in due to COVID-19 — a total standstill of production.

The manufacturer’s main supplier of crucial components permanently shut its doors without warning, bringing operations to a costly and screeching halt. Because there were no contractual provisions in place to require notice or provide alternate suppliers, this manufacturer spent weeks trying to find a replacement so production could pick up once again.

Desperate and without any response from the initial supplier, the OEM considered reshoring production back to its facilities as a last resort (something that did not go well previously).

Discover how VCC sprang into action for one client in crisis. In less than a week, our team toured the facility, hosted clients on-site, created a full plan of attack, and conducted all necessary onboarding.

Responsive Plan, Seamless Return to Production

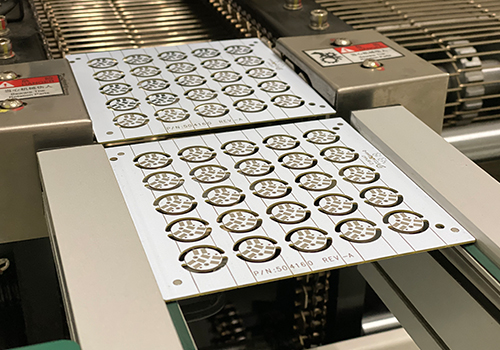

A distributor mentioned VCC as a viable option, and the manufacturer reached out to our team. In less than a week, we toured the facility and created an action plan to get the OEM up and running as soon as possible, providing turnkey PCB assembly, quality assurance, testing, and logistics.

In this OEM’s case, simply having a nearshore supplier in Mexico was not enough to mitigate the risks of disruption.

Going Nearshore: North America is Perfect for Partnership

Choosing a proven and adaptable partner ensures manufacturers can respond to ever-changing needs while capitalizing on the many benefits of nearshoring. Leveraging facilities in México for over 30 years, VCC helps clients gain a competitive edge through:

- Highly skilled engineering and production teams

- Real-time collaboration with designers

- Faster production and delivery times

- Value-added services to further reduce costs and lead times

- Tariff-free production close to home (and your customers)

Within North America, Mexico has emerged as the principal destination for this relocation of production, driven by a powerful combination of geographic, economic, and political advantages. Mexico's emergence as the preferred nearshoring destination is not a coincidence but rather the result of a powerful combination of inherent strengths and favorable policy frameworks.

To learn how nearshoring can help reduce supply chain risks, check out this free guide.

5 Ways to Reduce Supply Chain Risk with Nearshoring

Learn about the benefits of nearshore electronic manufacturing, including reduced production costs, shorter lead times, and enhanced intellectual property protection. Being closer to the market and having access to a highly skilled workforce can streamline the supply chain and improve product quality.

If you're looking to build a more flexible and reliable supply chain, this video is a must-watch. It provides a clear and concise overview of how proven nearshore capabilities can help you navigate a stressful and uncertain economic climate.