Flow measurement plays a critical role across industries where accuracy and reliability determine performance, safety, and compliance. In water treatment, flow sensors ensure proper chemical dosing and system balance. In the chemical and petrochemical sectors, precise flow measurement is vital for reaction control and leak detection. Medical devices such as infusion pumps or dialysis machines require tightly controlled liquid flow monitoring for patient safety. In food and beverage production, flow monitoring maintains consistency, sanitation, and quality control. Across these markets, sensor accuracy and compact integration are increasingly important as products shrink in size and adopt more complex geometries.

One of our customers needed to measure liquid flow and detect occlusions using an optical sensing method. Their device design presented a unique set of hurdles:

• The enclosure and PCB layout dictated that light must travel through a curved flow tube.

• Off-the-shelf lightpipes couldn’t achieve the sharp bends or performance levels required.

• The customer only had a 2D prototype concept—far from ready for production.

What they needed was a partner who could transform their vision into a 3D design optimized for real-world performance: controlling view angle, minimizing light loss, and simplifying mechanical integration.

Our Solution

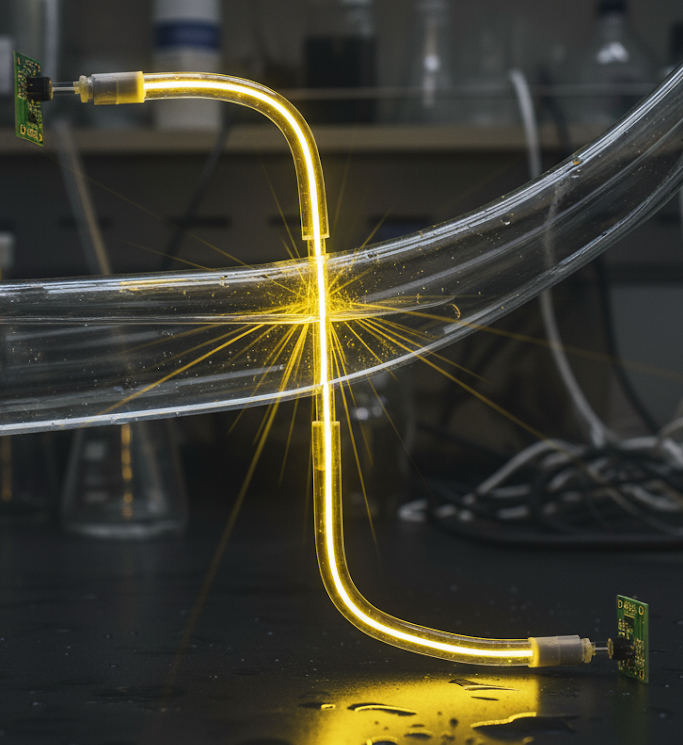

Our engineering team took the early concept and ran it through a full cycle of optical simulation and performance analysis. The breakthrough came from custom geometry.

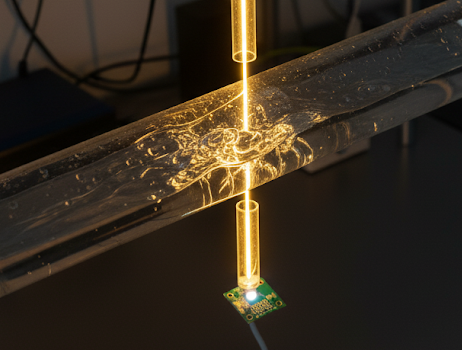

• We created a curved, two-lightpipe system—one for transmission and the other for reception.

• Leveraging Total Internal Reflection (TIR), the lightpipes efficiently guided light through the flow tube.

• We incorporated housing features to dramatically reduce light leakage.

• Custom lens geometry at entry and exit points improved directional control, maximizing the signal.

This tailored design not only solved the mechanical and optical challenges but also elevated the overall performance of the system.

The final design exceeded performance expectations:

• The impact was significant:

• +37.5% increase in LED light output

• +1800% gain in photodiode signal strength

• Simplified mechanical integration for faster assembly

• Elevated customer credibility with their OEM partner as an expert in embedded flow measurement

What began as a rough 2D sketch became a production-ready optical solution, delivering measurable improvements in both performance and customer trust.