Application Characteristics

Medical and dental products have (thankfully) come a long way over the years. Today’s patients can enjoy more non-invasive treatments through innovative products that utilize water laser technology.

As leading-edge dental devices become smaller and more portable, they must maintain the same level of safety, cleanliness, and performance as their more stationary counterparts — many requiring custom design solutions for their illuminated components.

When our client approached us with a long list of requirements for its dental device, we quickly provided a solution that met all client objectives and then some.

Application Requirements

For this water laser machine, the list of illumination design requirements was quite extensive:

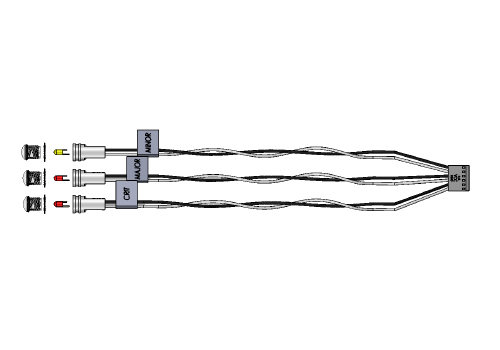

- The design called for a custom cable assembly with three LED socket assemblies

- Each of the socket assemblies would house removable LEDs

- The LEDs had to be easy to install through the front panel

- There was an isolation requirement to prevent the LED to excess water exposure

- The device needed to withstand constant exposure to water and cleaning solutions

Our engineers worked closely with the client to develop the ideal solution.

Water Laser Machine

The use of water laser technology in dental machines, which involves continuous fluid delivery, imposes unique and stringent environmental requirements on internal electrical components. The LED socket assembly must be isolated to prevent excess water exposure and must tolerate constant contact with water and clinical cleaning solutions.

Solution / Approach

Custom LED Assembly

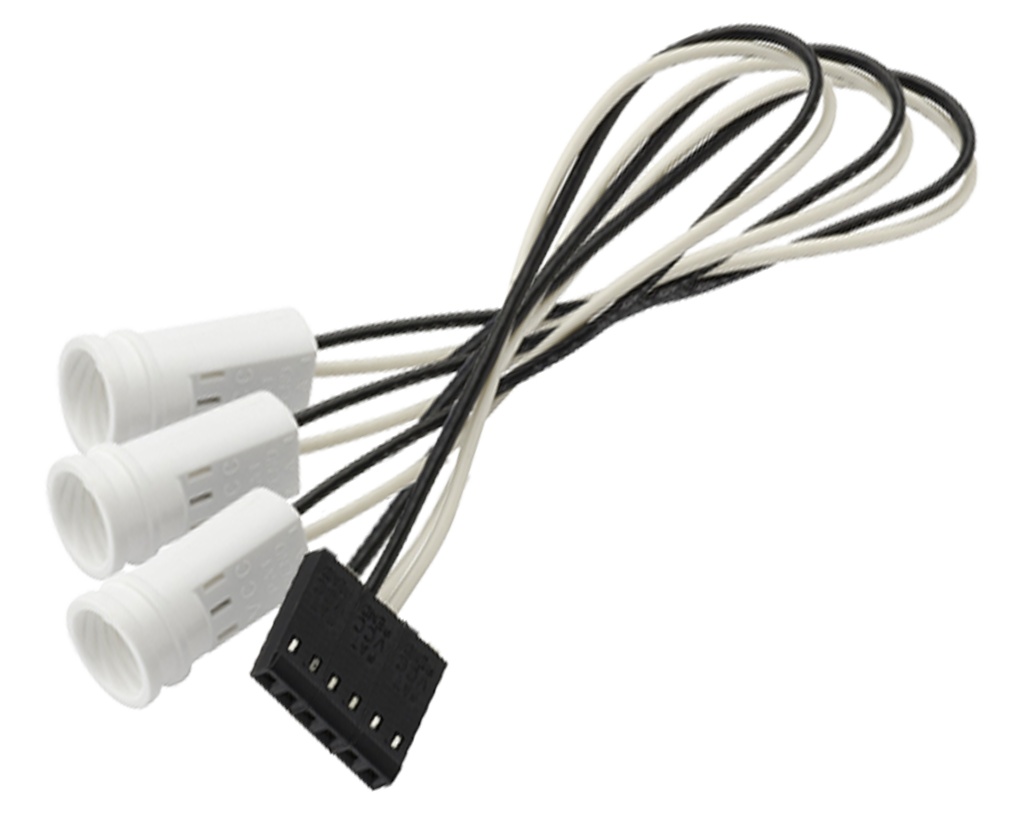

Using the build your own indicator option, which allows for customization of design using standard sizes and parts, we configured a solution that customized LEDs, wire size, length, color, and wire termination for the client.

Custom Cable Assembly

The Custom Cable Assembly was a central, specialized component engineered to meet the stringent demands of the water laser dental machine, particularly the need for reliable electrical connectivity in a fluid-intensive environment.

CNX440 5mm Panel Mount Indicator

Our team specified the CNX 440 Series cable assembly for its quick and easy connections between panel–mounted LEDs and the power source. We then integrated the assembly onto a custom cable with three replaceable LED sockets and added high-output, waterproof lenses.

CMS442 Lens

For this application, the blue CMS442 lens was used with the cable assembly. This threaded Fresnel lens includes a watertight seal due to a retaining ring and lock washer. With a NEMA 6P rating, the lens is protected from constant exposure to moisture from water and cleaning solutions.

Lenses are also available with clear and diffused lens, flanged and flangeless, multiple viewing angles, and various colors, including green, red, white, and yellow.

Value-Added Services

At VCC, we pride ourselves on having a seat at the table for designing medical technologies that improve the lives and safety of patients worldwide. Our custom cable and three-socket configuration quickly and efficiently provided the client exactly what was needed for its innovative device. Plus, we helped the client maximize efficiency and reduce production costs through using the Build Your Own Indicator option and nearshore manufacturing.

Our build your own indicator option delivered a custom, cost-effective LED assembly solution with three replaceable and LED socket assemblies.