Case Study

VCC delivers clear solution for industrial dishwasher manufacturer

Application Characteristics

When it comes to food service, food safety is job one. And there’s one piece of equipment that should always work overtime to help sanitize the serveware and utensils we use to enjoy our food at restaurants, hotels and resorts — the industrial dishwasher.

Industrial dishwashers may seem like they function similarly to those found in our homes. But, their volume capacity demands more water, more energy and often more power to run efficiently. And high-temperature commercial dishwashers use superheated water to wash, which eliminates the need for the additional step of sanitizing with chemicals.

These machines must provide safe, reliable operation in the high-vibration, high-heat and high-moisture environments. When they are well-designed, they also save energy while reducing costs for water, chemicals and labor for foodservice and retail operations.

When a leading industrial dishwasher manufacturer approached us, one of its innovative models was not only failing to operate properly, it was giving the manufacturer indigestion due to expensive warranty claims.

Solution/Approach

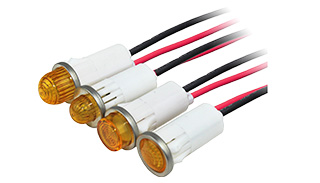

1092 Series Panel Mount Indicator

The VCC team specified the amber 1092 Series PMI with wire leads to provide consistent, reliable illumination in a panel mount indicator that would stay put during high-vibration operation.

By replacing the neon indicator with a 125V LED hi-hat lens with snap-fit mounting, our team provided a standard product that solved the client’s issue while providing greater efficiency and reliability. The PMI included:

• Snap- fit assembly – fast, tool-free assembly into 0.500” (12.7mm) panel hole

• Hi-hat lens – transparent diffused lens provides consistent illumination

• Wire leads terminal – a cost-effective and secure solution for keeping the PMI in place and eliminating potentially dangerous arcing due to loose connections

• Amber LED – communicates machine status in a reliable, energy-efficient LED with a longer life than the neon indicator used in the existing product design

Application Requirements

This industrial dishwasher’s blinking indicator is crucial to communicating with operators, as it is used to notify the end user when the machine needs attention, such as:

- Excess soap in the machine

- Obstruction of the spray nozzle

- Improper water temperature

- Blocked filter

Our client’s existing 125V neon panel mount indicator used 0.20” tabs to connect to the power source. Due to the constant vibration of the machine while in use, these indicators would vibrate out of place, causing a wide range of headaches — from blown fuses to transformers shorting out. These issues led to safety concerns, as well as expensive warranty claims. Fortunately, VCC knew exactly what was needed to resolve the issue.

For the manufacturer:

- Cost-effective design improvement

- Elimination of expensive warranty claims

- Enhanced operating life

- Standard product for manufacturing efficiency

For the end user:

- Safe, reliable operation

- No downtime due to maintenance or repair

- Extended operating life

- Enhanced food and operator safety

Value-added Service

Our design team quickly evaluated the client’s issue and recommended a standard product that not only solved the problem and eliminated costly warranty claims, but lowered production cost per unit by using terminals with wire leads.

Whether you need a custom design or have a unique design challenge, VCC is here to deliver the ideal product for your budget and goals. Contact our team today.