Application Characteristics

If there’s any place that needs optimal lighting it’s a hospital or health care facility. Hospital lighting plays a major role in supporting the well being and wellness of patients, staff, and visitors. While most health care organizations are focused on the bottom line and how to reduce energy costs, they should also consider how lighting design can deliver additional benefits for patients, staff and their operating budgets.

Good lighting has been credited with more than ambiance. It has even been linked to improved staff productivity, patient satisfaction and patient healing — the ultimate goal of health care facilities.

In environments like patient hospital rooms, getting the color temperature right is key to evoking an atmosphere that is less clinical and more peaceful. And white color temperature is ideal for setting the right mood. Patient room lighting creates a calming environment, supporting both patient well-being and staff efficiency. Hospital lighting design must balance functionality with comfort to enhance the overall healthcare experience.

Tailored lighting solutions for various spaces and interiors, such as patient rooms, corridors, and lobbies, are important to meet the unique needs of each area.

Downlighting is too harsh for patients, so low-profile, less-intrusive fixtures should also be considered wherever possible. The use of overbed lighting, ambient lighting, and specialized luminaires as part of curated collections provides a variety of lighting functions and supports the needs of healthcare spaces.

Application Requirements

In close collaboration with top electro-mechanical distributor, Hawk Electronics, and manufacturer representative, EK Micro, VCC was added to our client’s approved vendors. We then created a custom solution that achieved all of the large OEM manufacturer’s design requirements for its patient room night light:

- Energy-efficient and long-lasting operation

- Rugged and watertight construction due to exposure to harsh cleaning chemicals and other liquids

- Low-profile, low-glare illumination

- Appropriate color temperature to enhance patient experience

- Streamlined production processes

- Quick turnaround from design to final production

Solution / Approach

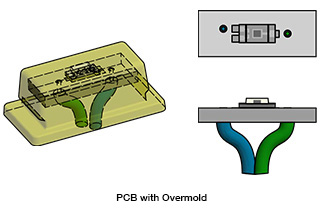

Our team developed a custom solution that included an overmolded transistor assembly. This component-level customization was crucial for maximizing production efficiencies. Our team of experts:

- Designed and prototyped a custom circuit board and photocell unit

- Worked closely with the client and completed several subprocesses to help the client streamline the manufacturing and assembly of the hospital room night light

- Overmolded the circuit board and photocell unit with High performance thermoplastic for added durability

- Designed and built test jigs to assure final assembly process meet the necessary requirements

An accelerated timeline helped our client get to market faster — we designed and shipped the custom product in 12 weeks and the first production order was delivered one month later.

Results & Benefits

VCC and the team delivered a custom product that:

- Reduced manufacturing costs thanks to snap-in assembly

- Enhanced device quality due to rugged, watertight construction

- Helped enhance patient satisfaction

- Saved the hospitals money with energy-efficient LED technology

- Delivered on production speed and innovation

Value-Added Services

VCC’s design team was able to quickly design, prototype and produce a custom component-level solution for our client in a matter of weeks.

How can we take your design to the next level? Contact us today to get started.

Case Study Media