In only three weeks, we created a custom light engine design that increased overall efficiency and performance by 14%.

Results & Benefits

VCC’s custom design delivered a solution worthy of rave reviews from theater owners and moviegoers alike.

Application Characteristics

The movie theater experience has come a long way since first screening silent films over 100 years ago. Today, the action — and communication — needs to take place on and offscreen during a movie.

And Venue Valet is bringing the Hollywood treatment to moviegoers, working with theater owners to outfit theater seats with call buttons that allow for in-seat food and beverage service. Our client is committed to providing easy and intuitive ways to order directly from theater seats without distracting from the action taking place on the big screen.

Whether it’s a movie theater or a home theater, lighting has the power to make or break the experience. To enhance overall quality, the viewing room should be dark and include just enough illumination for people to move around safely. This is where intelligent lighting design comes in.

Application Requirements

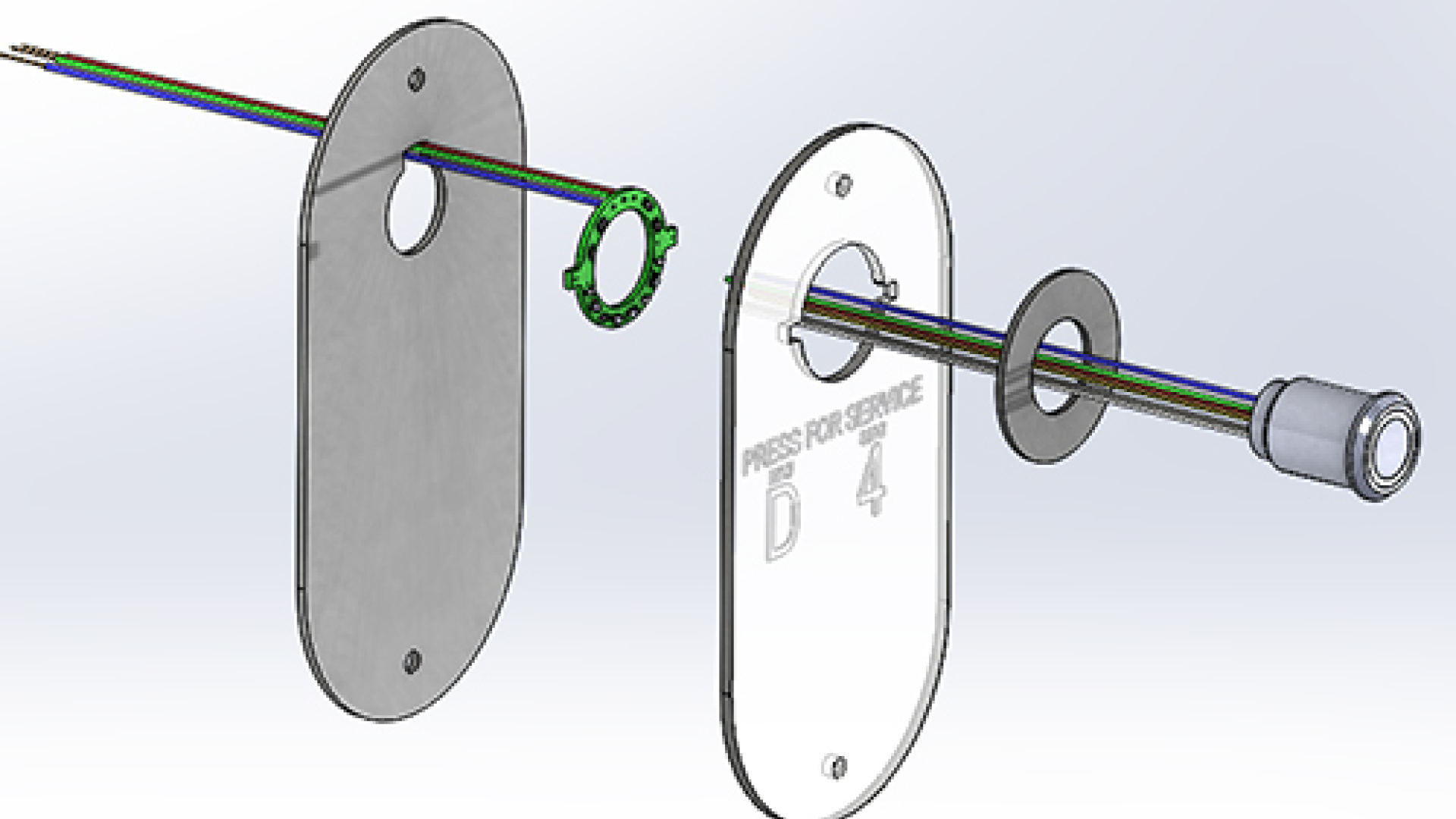

While installing in-seat call buttons on new seats is relatively seamless, retrofitting existing theater chairs in a way that is cost-effective and aesthetically pleasing is a more complex task — one that required cutting through fabric and plywood. That’s why Venue Valet developed the new all button with a ring light. This acrylic plate is laser etched with the theater logo and each seat number, requiring just a 1” hole in the chair for installation.

In addition to the illumination around the call button in the plate, there is also some light spray off the edge of the acrylic that helps illuminate the walkway.

With distracting hot spots and light pollution, the existing design was falling short of the desired effect — so Venue Valet enlisted our help.

Solution / Approach

Only a custom design solution would solve our client’s design issue, so:

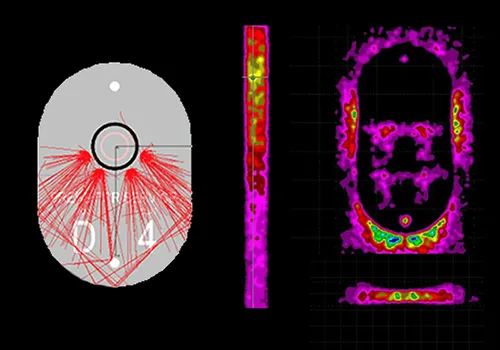

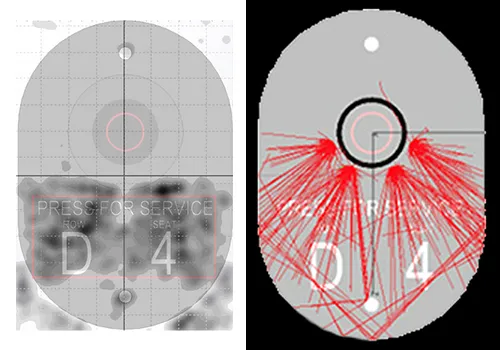

- Our team ran light simulations to determine where light was being lost and what footprint would yield optimal performance while reducing hot spots and light pollution

- We designed a small light engine with eight surface-mount (SMT) LEDs — four red and four white to meet the client’s needs

- We then developed a prototype to prove our solution would work in the real-life theater environment

- The custom design optimized the call button’s indication and delivered consistent illumination without hot spots or light pollution

In just three short weeks, VCC’s design team developed and prototyped the ideal solution that:

- Repositioned the inner and outer LEDs to ensure more light illuminated the letters

- Reduced bright spots on each side by ~14%

- Delivered cost savings by changing the thickness of the component from .25” to .187”

Value-Added Services

Leveraging extensive experience, VCC’s design team quickly designed, prototyped and produced the solution that exceeded our client’s expectations thanks to:

- Accelerated Timeline

- PCB Assembly Expertise

- In-House Capabilities

- Nearshore Manufacturing

- Testing

Our team was able to quickly optimize and test the ideal solution for minimizing light loss and maximizing performance of the PCB assembly.

Exponential Increase in Performance

Improved overall performance by 42%