Application Characteristics

Disinfecting the devices we use every day is something many people don’t spend much time thinking about.

Cleaning our keys, keyboards, credit cards, phones, and other personal objects is always a good idea. And in the age of coronavirus, it’s more important than ever. Here’s why:

- Coronavirus can live on surfaces for a few hours to a few days.

- Cell phones are 10x more contaminated than public restroom seats! Yet, 49% of people admit they don’t disinfect their electronics.

- Touching our faces is linked to the spread of coronavirus because the virus is transmitted through mucous membranes in the eyes, nose, and mouth.

- People touch the T-zone of their face almost 69 times per hour and other parts of their heads 50 times an hour.

This combination of factors puts most people at a greater risk of catching or spreading COVID-19. The good news is, UV light can help kill harmful germs and viruses on high-touch surfaces and household objects, including the SARS-CoV-2 virus that causes coronavirus.

To address the potentially life-threatening pathogens on everyday objects, French manufacturer Uvoji developed its innovative Uvo Care UV-C disinfection devices, which use light to sanitize a range of large and small objects without damaging any circuits in the electronic devices.

Of all the light on the UV spectrum (UV-A, B, and C), only UV-C lighting can kill 99.99% of viruses and bacteria. UV sanitizers use UV-C wavelengths to kill harmful bacteria and viruses on masks, keys, credit cards, phones, and more without harming the objects themselves.

Uvo Care is proven effective on viruses and other harmful bacteria, making it one of the most effective ways to disinfect homes, offices, and other environments against viruses like COVID-19.

Application Requirements

The client’s specifications for the LED UV-C disinfection box were stringent:

- Intuitive controls that require little to no instruction

- Fast, efficient, and simple device with no warm-up required

- Two disinfection cycle times ranging from 30 seconds to 3 minutes

- Durability for cleaning the outside of the device

- Cap touch buttons that could work behind the device’s thermoplastic exterior

- Adherence to performance levels of NFT72-281, a standard protocol for airborne surface disinfecting systems designed by the French standardization body AFNOR

- Reliable operation for the product’s 10-year lifespan

Uvo Care is available in two models, the Uvo Care and Uvo Care Flash, with the primary differences being the size of the device and the materials it can disinfect.

The standard Uvo Care model is designed for versatility, accommodating a larger useful disinfection volume of 230×150×90 mm. This volume allows for the sanitization of multiple smaller items or single larger objects such as tablets, wallets, and standard personal electronics.

The Uvo Care Flash model, conversely, must be dimensionally smaller than the standard model to facilitate the high-speed 30-second cycle. The Flash model strategically sacrifices volumetric capacity to achieve high operational speed, targeting rapid surface sterilization.

Results & Benefits

Our CSM capacitive touch sensors provided many benefits for the manufacturer and end-users:

- Uniform illumination and clarity thanks to advanced LED technology and an integrated circuit

- Reduction in warranty claims over product’s 10-year life because there’s no mechanical switch or mechanical moving parts to break

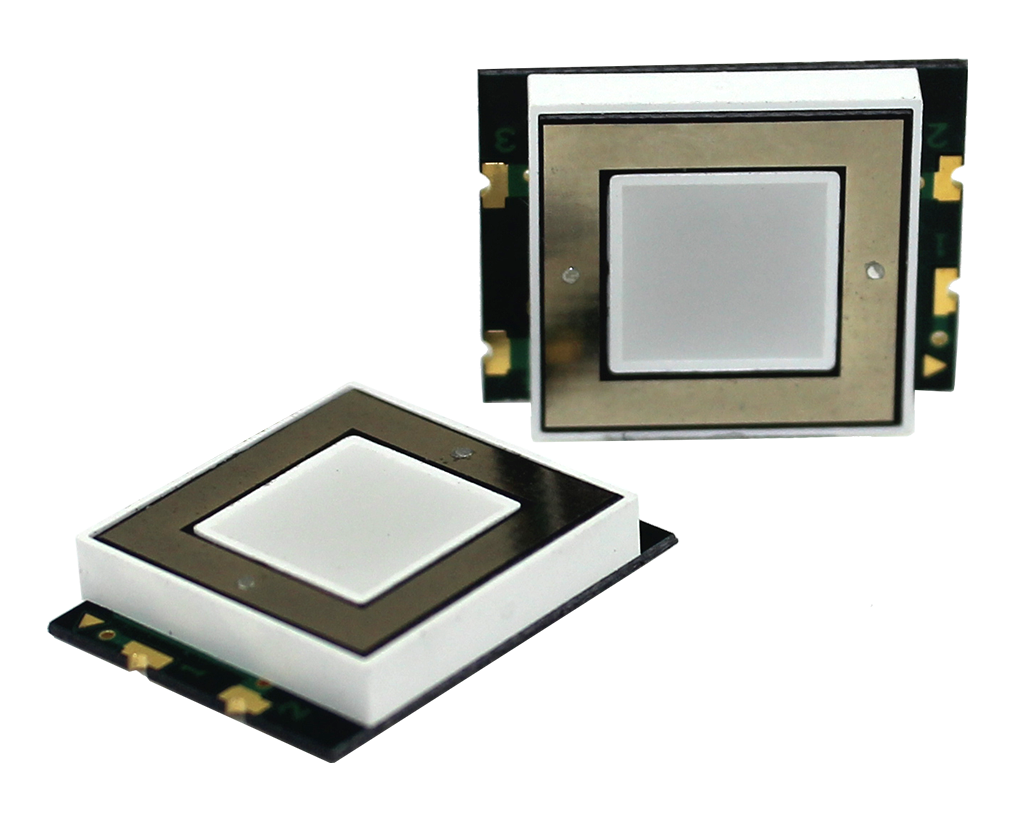

- Production efficiencies due to SMD mounting that simplifies assembly and production due to a simplified PCB design

- Sleek interface aesthetic consumers prefer because advanced technology is mounted behind the scenes.

Value-Added Services

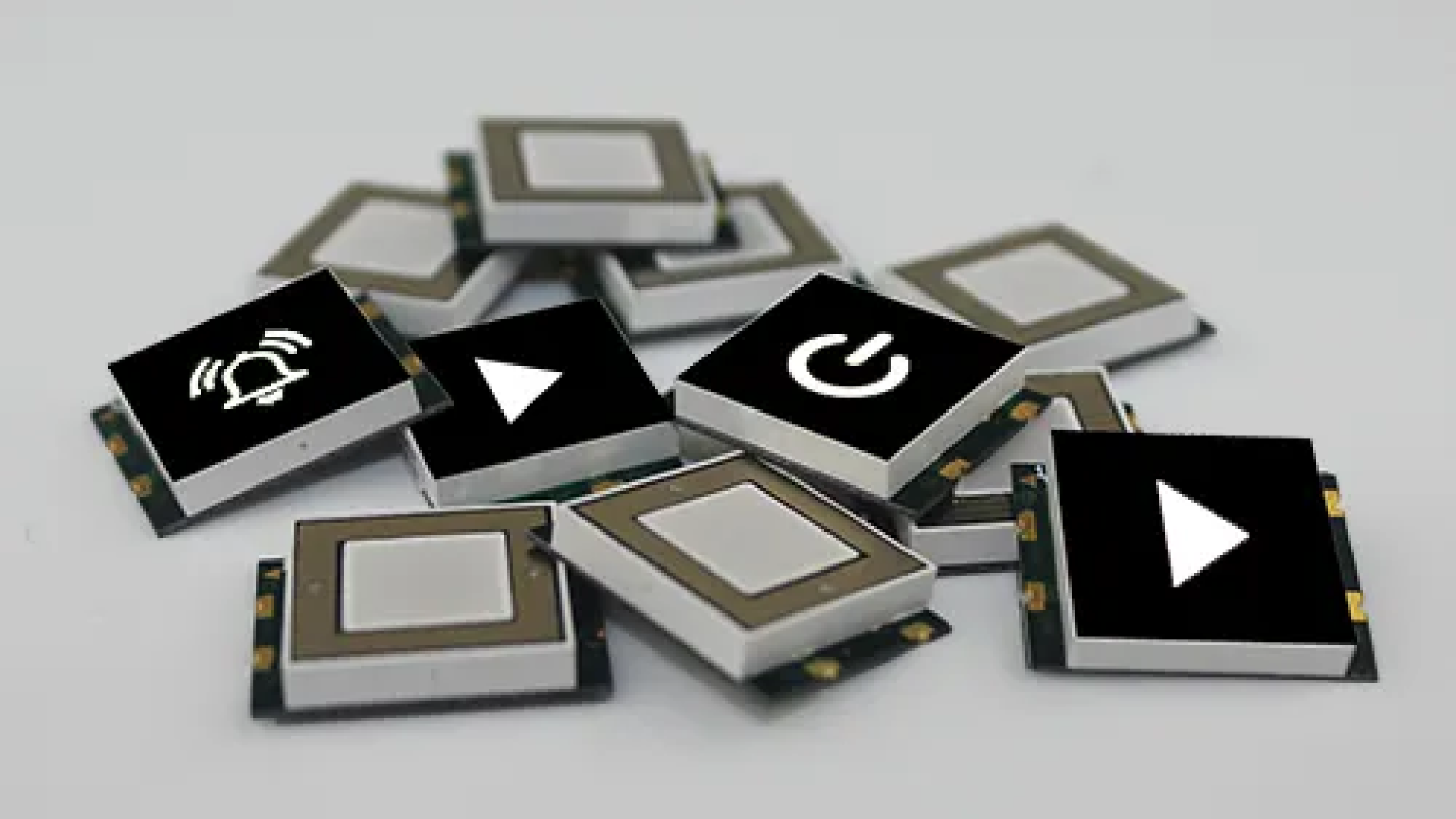

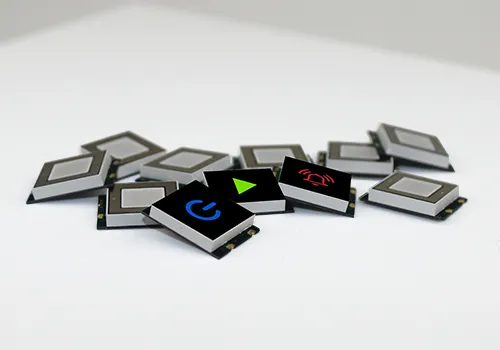

- Our CSM Series delivered the ideal combination of a standard available product with easy customization of the icons via screen printing.

- Cap touch technology made it feasible to remain true to the original design concept instead of using an unsightly push button to achieve design goals.

- Made with design flexibility in mind, the SMD mounting delivered time and cost savings in production.

Solution & Design

Through online research, Uvo Care’s engineers worked with our distributor Mouser to discover our CSM capacitive touch LED sensors

These innovative backlit sensors were the ideal solution because they addressed all of the client’s needs in a standard product and more. Our CSM Series:

- Streamlines the interface – using only two touch buttons for operation and indication facilitates a clean, modern aesthetic.

- Allows for easy cleaning – by mounting the sensors behind an acrylic sheet, the exterior of the device is durable enough for regular cleaning.

- Incorporates icons for intuitive operation – two icons were screen printed on the exterior plastic, one for each of the two disinfecting cycles for a seamless user experience.

- Leverages reliable LED technology – maximum brightness in milliseconds without mechanical parts that could easily break down.

- Accommodates a range of environments – the cap touch displays work well with a damp or dry finger or with touchscreen-compatible gloves.

- Utilizes innovative cap touch technology – ideal for electronics and modern devices, simple integrated circuit (IC) touchscreen that requires no mechanical parts that break down.

- Eliminates design challenges with small footprint – measuring only 15 mm x 15 mm x 3.2 mm, these sensors eliminate size as a constraint.

- Includes a variety of colors – available in five standard colors – white, super red, yellow, blue and green with the option for custom bi-color or RGB colors.

- Delivers automation – Microcontrollers can be employed in devices that need a degree of control to be applied by the user of the device.

- Delivers additional versatility – can be used with microcontroller, bus buffer or flip-flop buffer, depending on the desired action and configuration, latching switch or standard momentary switch.

A white CSM sensor was used to indicate each of the disinfecting cycles. By screen printing icons onto thermoplastic sheets, the HMI was enhanced for intuitive operation.

Because the cap touch sensors were so simple to use, Uvoji engineers simply followed the instructions on the product data sheet for issue-free design and performance.

So, how can Illuminated Buttons Enhance Operation for UV Light Sanitizing Box?

The illuminating capacitive touch buttons enhance the operation of the UV light sanitizing box primarily by ensuring functional clarity and maximizing hardware reliability in a high-speed system. Since the Uvo Care platform provides two distinct, material-dependent disinfection cycle times, the user interface must be unambiguous. The integrated, advanced LED technology delivers uniform illumination and clarity, allowing users to intuitively select the correct dosage required to meet certified virucidal efficacy standards.

Furthermore, the choice of non-mechanical capacitive touch sensors directly supports the device’s critical durability requirements. By eliminating traditional switches and moving parts, this design minimizes wear and tear, which is essential for models supporting high-throughput.. This focus on reliability helps ensure the UV light sanitizing box can achieve its specified maintenance-free service life of over 10 years, leading to a reduction in warranty claims.

VCC’s CSM Series is exactly what we needed. Innovative capacitive sensors that could be easily customized with icon overlays for a sleek aesthetic and optimal user experience. The production efficiencies are a bonus!

Case Study Media