As engineers, we know that a well-placed LED or light pipe is more than a visual detail, it’s often the difference between a product that’s intuitive and safe, and one that creates confusion or fails in the field. At VCC, LEDs and light pipes are at the core of what we do, and the opportunity lies in pushing beyond “off-the-shelf” applications to deliver optimized, application-specific solutions.

This guide goes deeper into the how and why of LED and light pipe integration, exploring design considerations, real-world challenges, and advanced applications across industries.

The "How" and "Why" of LED Design Choices

LED Types and Their Technical Roles

● Through-Hole LEDs: High durability and ideal for applications requiring mechanical robustness, but limited in compact designs.

● SMD LEDs: Superior for space-saving and high-density PCB layouts. Offer better optical coupling with light pipes.

● High-Power LEDs: Perfect for applications demanding maximum brightness (aerospace, automotive), but introduce thermal management challenges.

● Bi-color and RGB LEDs: Enable status differentiation and multi-signal communication with fewer components.

Why These Choices Matter

The decision is not about light output alone. Engineers must consider:

● Viewing angle: Wider vs. narrower beams depending on end-user interaction.

● Forward voltage & current: To ensure compatibility with power supply and driver circuits.

● Thermal dissipation: Heat sinks or PCB copper pours to maintain LED life expectancy.

Light Pipes: Guiding Light with Precision

Light pipes are not just “plastic guides.” Their design directly impacts optical efficiency and usability.

● Rigid Light Pipes: Deliver precise pathways, but require careful alignment tolerances.

● Flexible Light Pipes: Solve space constraint challenges by routing light around corners or obstacles.

● Custom Geometries: Critical for applications where branding or UI differentiation is key.

Key Design Considerations

● Coupling Efficiency: LED-to-light pipe alignment is everything. Even a fraction of a millimeter misalignment can result in major light loss.

● Surface Finish: Polished pipes increase transmission, while frosted tips diffuse for wider visibility.

● Mechanical Integration: Clips, panel mounts, or adhesives must withstand vibration and temperature cycling.

Problem-Solving: Common Engineering Challenges

1. Uneven Brightness Across Indicators

● Cause: Different LED tolerances or inconsistent coupling.

● Solution: Use binned LEDs, diffused light pipe tips, or current-balancing resistors.

2. Light Bleed Between Indicators

● Cause: Inadequate optical isolation.

● Solution: Add barriers, opaque housings, or use black-tinted light pipes.

3. Thermal Stress on LEDs

● Cause: High drive currents in compact assemblies.

● Solution: Heat sinking, thermal vias, or moving to lower-power LEDs paired with efficient light pipes.

4. User Misinterpretation

● Cause: Colors not intuitive to function (e.g., using blue instead of amber for caution).

● Solution: Follow industry standards: Green = safe, Amber = warning, Red = fault.

Unique Applications Across Industries

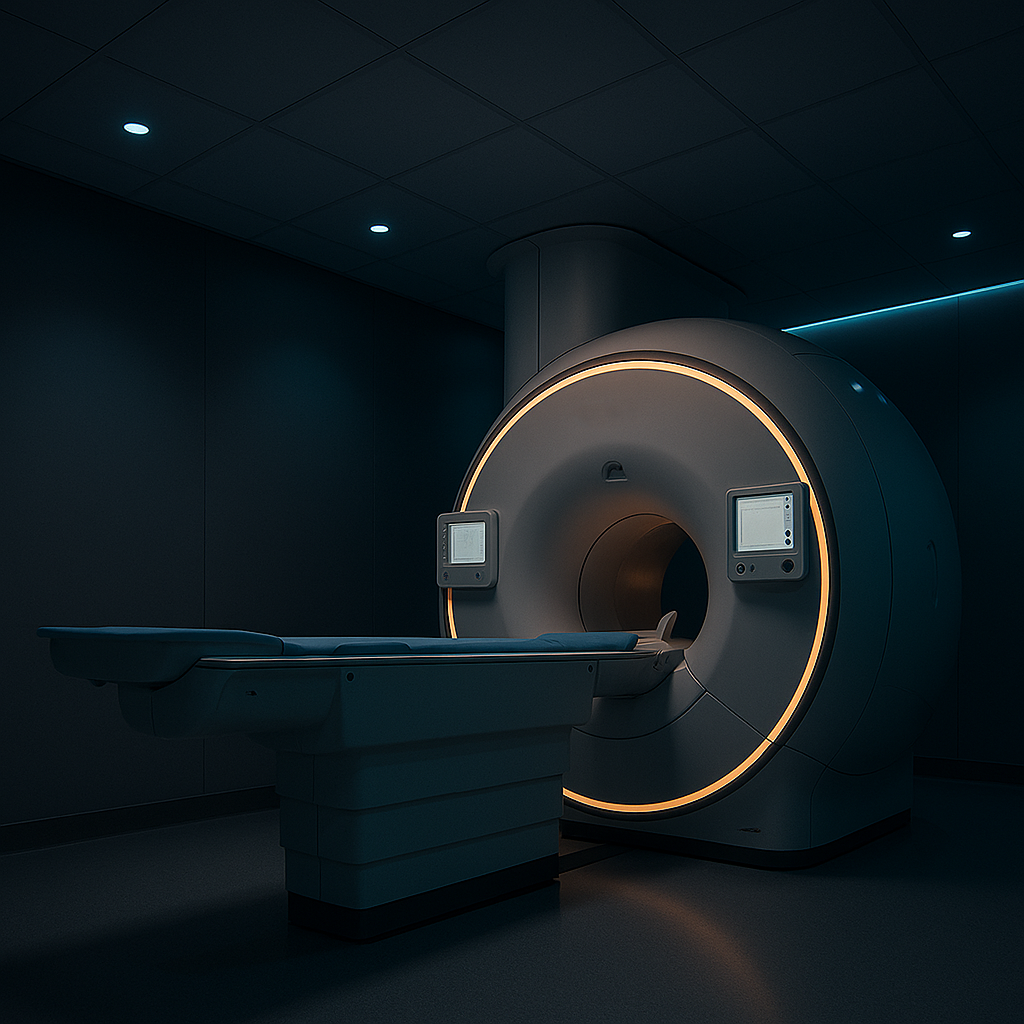

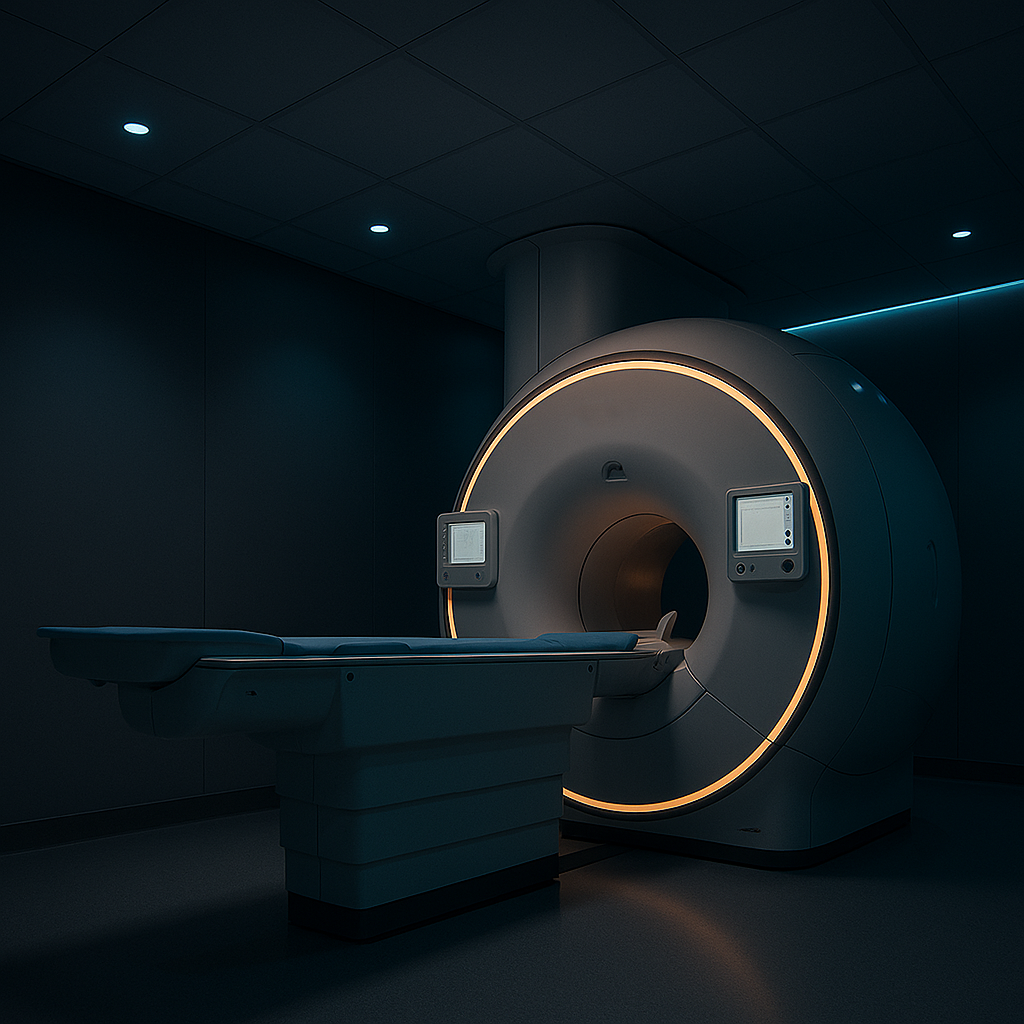

● Medical Devices: Sterile environments demand sealed, IP-rated indicators. Light pipes allow LEDs to stay behind protective barriers while still providing clear signals.

● Aerospace: High vibration requires robust mounting and redundancy. Bi-color LEDs with rigid light pipes provide clear status without adding complexity.

● EV & Automotive: Dashboards and charging stations rely on custom LED arrays with diffused light pipes for immediate, intuitive feedback.

● Industrial Automation: Operators depend on bright, consistent indicators across large panels. Using a single LED with a multi-output light pipe reduces maintenance and power draw.

Conclusion: Engineering Better HMIs

LEDs and light pipes are not just components, they are critical design elements that define the usability and reliability of your HMI. By understanding the technical nuances from optical efficiency to thermal management, engineers can deliver products that are both innovative and fail-safe.

At VCC, our role is to move beyond being a parts supplier. We partner with engineers to solve these challenges and create custom illuminated solutions that make technology clearer, safer, and more efficient.