Smarter Panels, Safer Operations

Industrial automation is advancing rapidly, and with it comes the demand for more reliable and efficient ways to communicate system status. Once limited to basic on/off lights, control panel indicators have evolved into high-performance tools that enhance visibility, reduce downtime, and improve safety across critical operations.

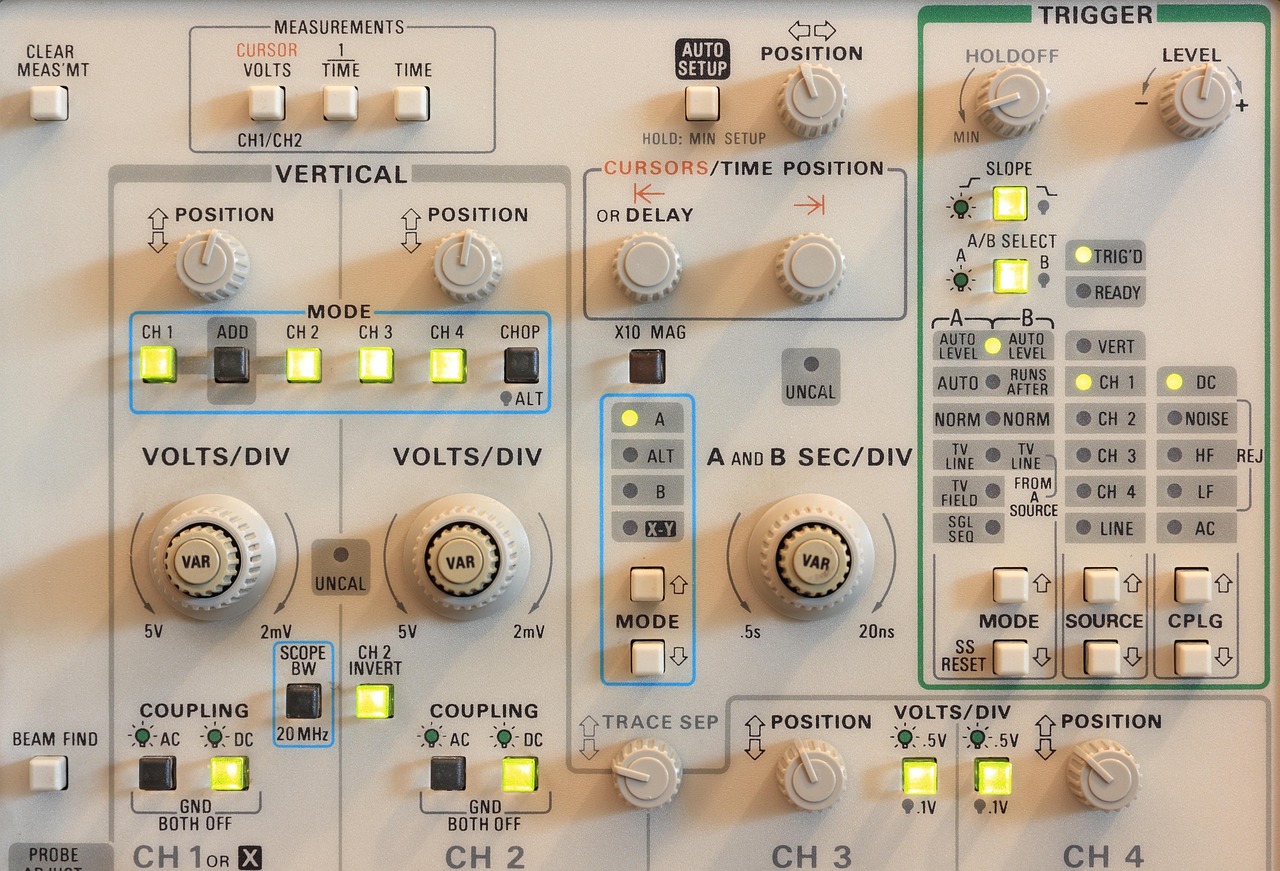

Today’s LED indicators are essential in modern control panels—not just as signaling devices, but as integral components for system monitoring, diagnostics, and operator response.

Why Traditional Indicators No Longer Cut It

Conventional incandescent lamps were once the standard in control panels. But in demanding environments—where vibration, temperature shifts, moisture, and electrical noise are common—they fall short. Typical issues include:

● Short lifespan due to filament burnout

● Low visibility in dusty or high-glare areas

● Frequent maintenance, leading to unnecessary downtime

In industries where uptime is critical, unreliable indicators can result in miscommunication, slower response times, and even safety risks.

The LED Advantage

LED indicators provide a superior alternative. Built with solid-state technology and durable materials, they deliver consistent performance in virtually any condition. Key benefits include:

● Long-Term Reliability: With no moving parts, LEDs routinely offer over 50,000 hours of operation.

● Enhanced Visibility: Bright, color-accurate lighting ensures system status is clearly visible, even through tinted or reflective panels.

● Multicolor Output: Bicolor and tricolor designs can display multiple states from a single indicator, reducing the need for extra components.

● Instant Illumination: LEDs reach full brightness immediately, supporting faster diagnostics and emergency response.

● Energy Efficiency: Consuming minimal power, LEDs generate less heat and contribute to overall energy savings.

Engineered for Tough Industrial Environments

Industrial environments are anything but forgiving. VCC’s LED indicators are purpose-built to perform in the face of constant wear and exposure:

● Vibration Resistance: Threaded housings and secure mounting options keep indicators stable in high-motion settings.

● Sealing & Protection: Many models meet IP65, IP66, or higher standards for resistance to dust, water, and chemicals—ideal for food processing, manufacturing, and outdoor applications.

● Electromagnetic Compatibility: Built-in shielding helps prevent signal interference in increasingly connected factory floors.

● Wide Temperature Range: Designed to operate in both hot and cold extremes without compromising performance.

Real-World Applications

LED indicators are now standard across sectors that demand precision and durability:

Automotive & Manufacturing

Rapid assembly lines rely on instant, visible status updates. LED indicators improve operational flow and minimize downtime.

Food & Beverage

In sanitary environments, sealed indicators withstand routine washdowns and chemical exposure without losing clarity or function.

Energy & Telecom

Outdoor-rated indicators reduce maintenance on wind turbines or communication towers by eliminating the need for frequent bulb replacements.

Backed by Compliance and Quality Standards

Every LED indicator should meet the demands of industrial regulation. VCC’s products are tested and certified to align with the most trusted global standards:

● UL, CE, RoHS, and cURus certifications

● Ingress protection ratings (IP65 to IP67)

● Compliance with color-coding standards like NFPA 79 and IEC 60204-1

● Surge and ESD protection for enhanced system stability

Technical documentation includes test data, MTBF analysis, and certification details to support specification and compliance efforts.

How Modern LED Indicators Affect the Industries We Serve

Medical Industry

LED indicators are indispensable for patient safety and optimizing operational efficiency. They allow medical professionals to instantly assess the status of critical devices, immediately signaling an error or malfunction and prompting urgent action. In the fast-paced healthcare environment, these lights streamline processes by rapidly conveying essential information.

Transportation Industry

LED indicators are important for enhancing safety, streamlining traffic flow, and communicating crucial machine status and operational modes across various vehicles and transportation infrastructure.

Industrial Sector

Modern LED indicators are instrumental in achieving increased efficiency, reducing downtime, and enhancing safety across a multitude of industrial applications. Panel indicator lights are a crucial component for monitoring production lines, machinery, and control systems within manufacturing environments.

Energy Industry

Modern LED indicators are pivotal for improved system monitoring and diagnostics in multiple energy applications. They are essential for communicating system status, facilitating diagnostics, and enabling rapid operator response to control some of the most volatile resources available.

Aerospace Industry

Modern LED indicators ensure critical pilot awareness and system reliability, serving as the standard in today's aerospace systems. They are crucial for verifying the proper functioning of components, thereby enhancing the overall safety, functionality, and efficiency of electronic systems within aircraft.

Iot Industry

LED indicators are instrumental in enabling smart systems, facilitating remote monitoring, and enhancing data visualization. IoT connects everyday objects to the digital realm, and LED displays serve as high-impact visual interfaces that significantly enhance real-time information dissemination and interactive experiences. These indicators are increasingly integrated into smart home devices such as thermostats, security systems, and energy management tools.

Q&A

Q1: What makes LED indicators better than older bulbs?

LEDs last longer, use less energy, and offer better visibility in challenging environments.

Q2: Can I retrofit existing panels with LED indicators?

Yes. Many models are designed to fit standard panel cutouts for easy upgrades.

Q3: Are LED indicators safe for outdoor or wet conditions?

Absolutely. Models with IP65 to IP67 ratings are built for use in wet, dusty, or chemically exposed settings.

Q4: Can a single LED show multiple statuses?

Yes. Multicolor indicators (bicolor or tricolor) allow one device to communicate several states, simplifying panel layouts.

Q5: What standards do VCC LED indicators meet?

Depending on the model: UL, CE, RoHS, IP ratings, and color compliance with NFPA and IEC standards.

LED indicators aren’t just a component upgrade—they’re a step forward in system intelligence, safety, and efficiency. Whether you're building advanced control systems or modernizing legacy equipment, LED indicators from VCC provide the performance and peace of mind you need to stay ahead.