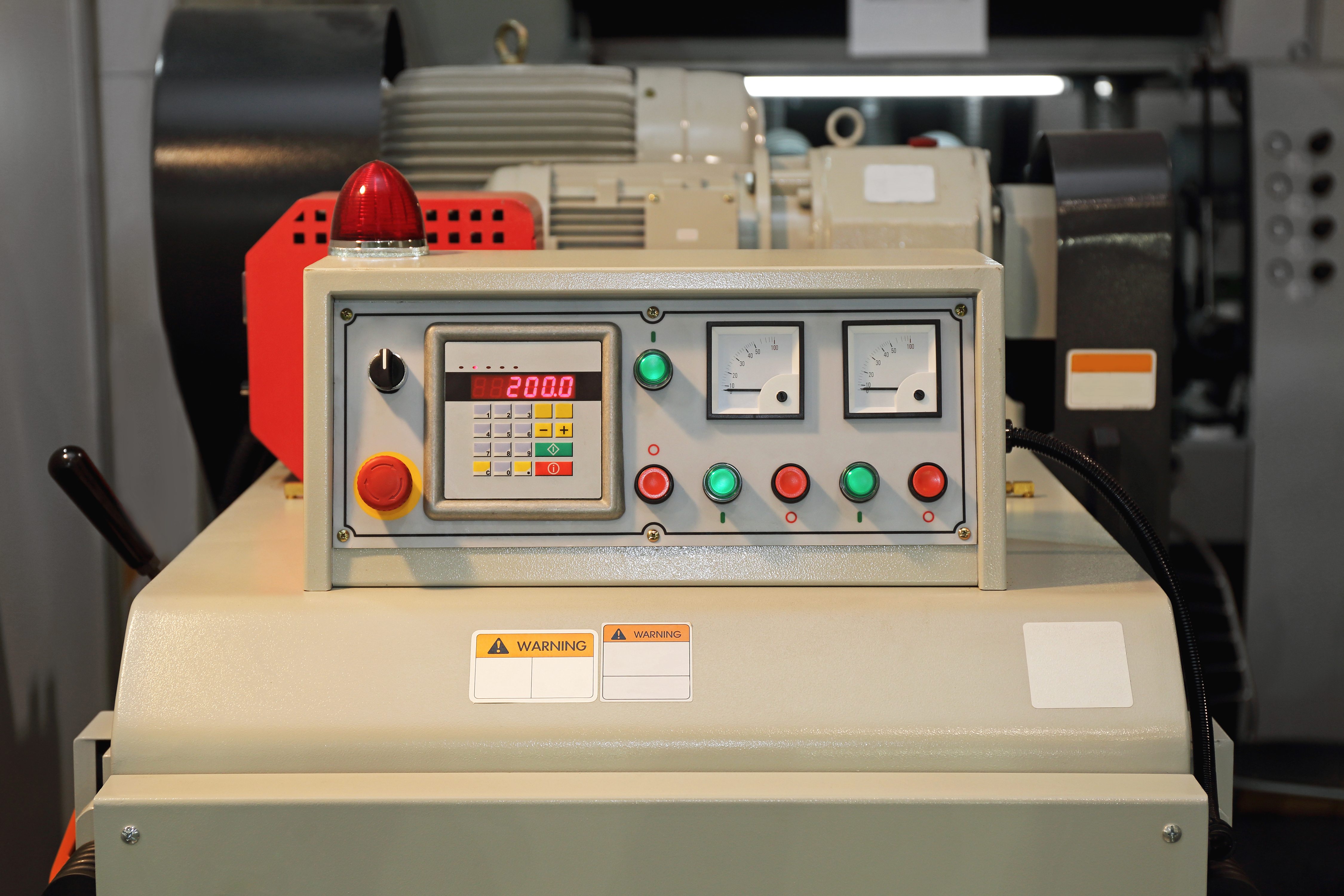

In the demanding world of industrial, medical, and automotive applications, Human-Machine Interface (HMI) components are often the first point of contact with harsh realities. From relentless vibration and extreme temperatures to corrosive chemicals and pervasive dust, these environments relentlessly test the limits of electronic systems. A seemingly minor component failure in an HMI can lead to critical visibility issues, safety hazards, and costly downtime. At VCC, we understand that true reliability is engineered from the ground up. Our commitment to comprehensive environmental robustness ensures that every HMI component—from light pipes and LEDs to panel mount indicators and membrane switches—is built to perform flawlessly, even in the most unforgiving conditions.

The Unyielding Challenge of Harsh Environments

HMI components face a gauntlet of environmental stressors that demand exceptional resilience:

-

Mechanical Stress: Constant vibration, shock, and impact, common in heavy machinery or transportation systems, can lead to misalignment or mechanical failure if not properly addressed.

-

Climatic Stress: Extreme operating and storage temperatures, high humidity, moisture, and UV exposure can degrade materials and compromise optical performance over time.

-

Chemical Exposure: Contact with cleaning agents, oils, or corrosive chemicals can lead to material degradation and loss of functionality.

-

Ingress Protection: Dust, dirt, and water ingress can short-circuit electronics, obscure displays, and lead to catastrophic failures.

-

Electromagnetic Interference (EMI) & Electrostatic Discharge (ESD): Unwanted electromagnetic signals and sudden static discharges can disrupt circuits, causing erratic behavior or permanent damage to sensitive electronics.

Without meticulous engineering, these stressors can result in poor visibility, mechanical failure, and non-compliance with essential safety and performance standards.

VCC's Engineering for Unmatched Durability

VCC's approach to building robust HMI components is holistic, integrating advanced material science, intelligent design principles, and rigorous validation.

Material Science: The Foundation of Resilience

The longevity and performance of an HMI component begin with the right material selection. VCC meticulously chooses and, where necessary, custom-blends materials to meet specific environmental demands:

-

Light Pipes: Primarily crafted from optical-grade polycarbonate and acrylic, VCC's light pipes are selected for their thermal stability and resistance to discoloration under prolonged stress. Custom blends are engineered to resist vibration and maintain long-term optical clarity.

-

LEDs: Our high-brightness LEDs, such as those in the PML50 series, utilize advanced InGaN and AllnGaP technologies, chosen for their robust performance and long operational life, even in challenging conditions.

-

Membrane Switches: The graphic overlays are made from durable polyester or polycarbonate, selected for their inherent chemical resistance, abrasion resistance, and UV stability. Adhesives, typically pressure-sensitive acrylics, provide strong bonding and resistance to humidity, water, temperature cycling, and various chemicals.

Design Principles: Building Inherent Strength

VCC's engineering team integrates specific design features to ensure inherent robustness:

-

Sealed Construction: For membrane switches and panel mount indicators, multi-layer construction and perimeter gaskets create a sealed barrier, providing superior resistance to moisture, dust, corrosive chemicals, and gases. This sealed design is crucial for achieving high Ingress Protection (IP) and NEMA ratings.

-

Vibration-Tested Geometries: Techniques like snap-fit designs and heat-staking are employed to maintain integrity under mechanical shock and vibration. The PML50 series, for instance, is specifically designed to be resistant to shock and vibration, featuring a "Double D" mounting hole that prevents rotation during installation.

-

Thermal Stability: Components are designed to maintain stable performance under abrupt temperature shifts and electrical surges, minimizing degradation or restart delays. The PML50 series, for example, has an operating temperature range of -25°C to +80°C and a storage temperature range of -30°C to +100°C.

-

EMI/ESD Protection: VCC's custom HMI solutions include integrated EMI/ESD protection. Our flexible light pipes offer inherent immunity to EMI and do not conduct or transfer ESD pulses. Membrane switches can incorporate conductive inks or mesh layers for EMI shielding, and board-mount light pipes can provide ESD protection for sensitive components.

Rigorous Testing and Validation: Proving Performance

VCC's commitment to durability is validated through a comprehensive suite of rigorous testing methodologies, ensuring that every component meets or exceeds industry standards:

-

"Thousands of Cycles" Testing: Our designs, particularly for light pipes, are tested through thousands of cycles to ensure resistance to vibration and maintain long-term optical clarity. This includes testing designs that handle angles up to ±45°.

-

Environmental Reliability Testing: Components are subjected to extreme temperatures and humidity to simulate real-world conditions, ensuring sustained performance in diverse operational environments.

-

In-Situ Testing: VCC emphasizes the importance of testing light pipes at enclosure fit-out and during final integration.

-

Compliance and Certifications: VCC products are built to meet a comprehensive array of international environmental and safety standards, including UL, cUL, CE, RoHS, REACH, NEMA, and various IP ratings. For example, the PML50 series carries an IP67 rating, signifying complete protection against dust and temporary immersion in water.

This rigorous validation process, combined with our precision engineering, has yielded tangible results. For instance, one OEM reduced operator error rates by 8% by integrating VCC's fluid-sealed light pipe system in food processing environments.

The VCC Advantage: Beyond Compliance

At VCC, engineering robustness is not merely about meeting minimum requirements; it's about a proactive commitment to delivering HMI solutions that enhance safety, improve operational efficiency, and provide long-term value. Our deep technical expertise, coupled with our rigorous design and testing protocols, ensures that your HMI components will withstand the toughest challenges, reducing costly downtime and ensuring reliable visual communication when it matters most.

By partnering with VCC, you gain access to:

-

Unmatched Expertise: A multidisciplinary team of engineers dedicated to solving complex HMI challenges.

-

Precision Engineering: Designs optimized for optical performance, material resilience, and mechanical stability.

-

Proven Reliability: Components validated through extensive testing to ensure long-term durability in harsh environments.

-

Supply Chain Resilience: Nearshore manufacturing in Mexico provides consistent quality and predictable pricing.