Case Study

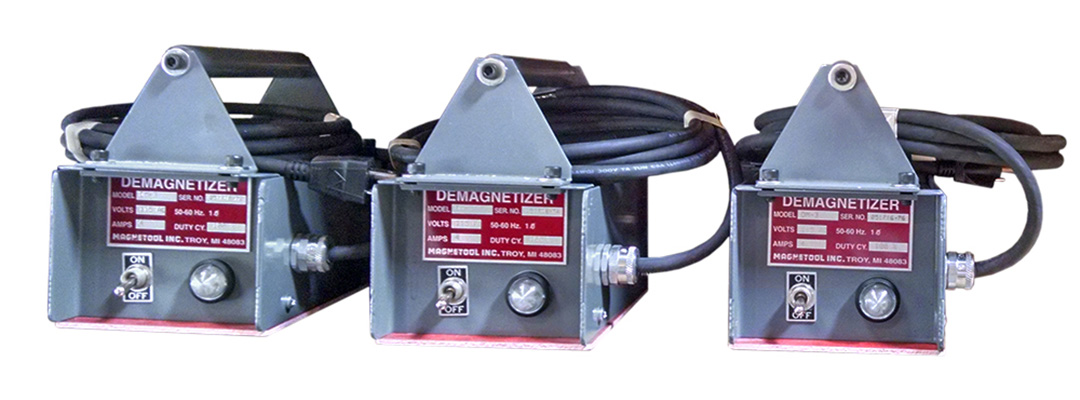

Demagnetizer Control Panel

Project

Demagnetizer control panel in heavy-duty industrial machinery.

Application Characteristics

Modern industrial manufacturing processes impose limits for remanent magnetism on components. Demagnetizers are used in various industrial applications to ensure proper operation of machines. Often, this equipment is exposed to harsh environments including vibration, extreme temperatures, humidity, shock (dirty power), dust/dirt, fluids, and more. The demagnetizer interface is an important safety feature, informing machinists about the operational status of the demagnetizer.

The reliable interface not only needs to be rugged enough to withstand the toughest environments, but it also needs to meet brightness requirements and feature a wide viewing angle.

Panel Mount Indicator Provided

VCC understands that industrial environment provides a unique set of challenges when designing heavy-duty machinery. The CNX718 LED panel mount indicator uses a high-intensity LED with a wide 180 degree viewing angle, a dome-shaped clear lens, and a front-panel mount.

The CNX718 is easily viewable to ensure machine operators are quickly and properly informed of any changes with the operational status of the demagnetizer.

They also feature .187″ tab terminals or 6″ wire leads, and are available in four voltage configurations: 5, 12, or 28 VDC, and 120 VAC.

Result & Benefits

VCC’s illuminated components allow machine operators to make better, more informed decisions. Through communication with light via the illuminated communicator control panel, machinists have better control of systems, ensuring proper performance and increasing safety.

Value-added Service

VCC understand the importance of visual communications and brings value to your design challenge. VCC becomes an extension of your design team and can provide technical advice and value to your design challenge.