In the intricate world of modern product design, illumination is far more than just turning on a light. It's about precise control, aesthetic integration, and reliable performance that directly impacts user experience and product functionality. Custom light pipes are the unsung heroes of this domain, efficiently channeling light from an LED source to its intended destination, whether it's a critical indicator or a sophisticated display.At VCC, we don't just move light; we engineer its journey with unparalleled precision, transforming illumination challenges into seamless, high-performance solutions.

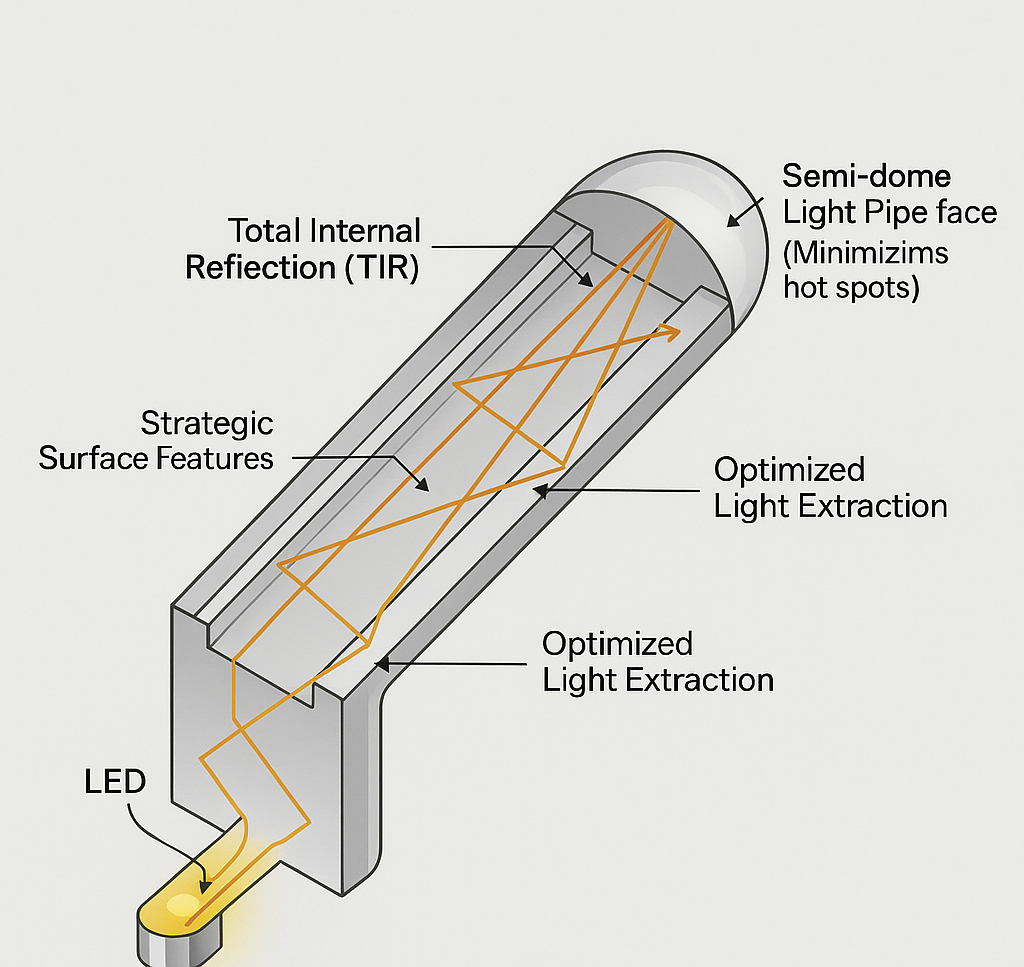

The fundamental principle governing light pipe efficiency is Total Internal Reflection (TIR). When light travels through a denser medium, like the optical-grade plastic of a light pipe, and strikes an interface with a less dense medium (typically air) at an angle greater than its "critical angle," it is entirely reflected back into the pipe. This phenomenon allows light to be channeled along the pipe's length with minimal loss.

However, the true artistry of light pipe design lies in a fascinating paradox: while TIR is crucial for containing light, it must also be strategically broken to allow light to exit the pipe at the desired location and with the intended distribution. Without this controlled disruption, light would largely remain trapped within the light pipe. This intricate balance between maintaining TIR for efficient transmission and deliberately breaking it for controlled output is where VCC's precision optical engineering truly shines.

VCC's Precision Optical Geometry in Action: Engineering Light with Intent

At VCC, our "optical geometry" is not a mere design parameter; it's a meticulously crafted science. We engineer every aspect of the light pipe's internal and external surfaces to precisely control light behavior. This includes:

● Strategic Surface Features: We design specific internal surface features, textures, and strategic coatings that are engineered to strategically interrupt TIR. These features alter the angle at which light strikes the surface, forcing it to exit the light pipe exactly where and how it's needed. This meticulous engineering ensures "uniform illumination" and "minimized light loss".

● Optimized Light Extraction: Our designs are tailored to achieve highly specific illumination goals, such as precise light shaping for complex displays or targeted directional illumination. For instance, our semi-dome light pipe faces are engineered to minimize "hot spots" while providing a soft, uniform glow and maintaining a wide viewing angle, such as the 120-degree viewing of our LFB Series. Overall, VCC light pipes are capable of providing viewing angles up to an impressive 160 degrees.

● Eliminating Imperfections: We proactively address common illumination issues like "LED light bleed" and "hotspots". Our designs ensure that light exits the light pipe's surface in the appropriate direction, preventing unintended leakage or distortion.

This level of detail in optical geometry allows us to deliver custom light pipes that achieve superior performance, ensuring clarity, consistency, and aesthetic appeal in your final product.

The Power of Advanced Simulation and Optical Modeling

Bringing these intricate optical geometries to life requires more than just theoretical knowledge; it demands cutting-edge tools. VCC leverages the "latest light modeling software" and advanced "ray tracing" capabilities to conduct thorough optical light simulations.

Our simulation-driven design process allows us to:

● Virtual Prototyping: We meticulously track the path of light through the proposed light pipe design in a virtual environment. This enables our engineers to devise optimal illumination solutions and accurately predict optical performance before any physical material is committed.

● Optimize and Refine: Through iterative simulations, designs are refined and optimized until all ideal optical requirements are met. This process helps us virtually eliminate light losses and proactively identify and resolve potential issues like hotspots and light bleed during the early design phase.

● Reduce Costs and Accelerate Development: By pinpointing design innovations and validating performance virtually, we significantly reduce the need for costly physical tooling modifications and shorten overall development times. This means faster time-to-market and reduced development risks for your product.

From Design to Reality: VCC's Rapid Prototyping and Manufacturing Precision

Once simulations confirm the viability of a design, VCC moves swiftly to physical prototyping and production. We utilize in-house 3D printing capabilities to produce plastic light pipe prototypes. These prototypes are remarkably accurate, typically 90% true to the finished product. This high fidelity provides you with the confidence to invest in final tooling, knowing that the design has been thoroughly validated in a tangible form.

Our state-of-the-art manufacturing facility in Mexico ensures that once tooling is complete, fabrication and assembly are conducted with the utmost precision and quality. This nearshore manufacturing capability provides numerous advantages, including enhanced quality control and supply chain efficiency, ensuring you receive a superior product.

The VCC Advantage: Your Partner in Advanced Illumination

Choosing VCC for your custom light pipe needs means partnering with a leader in precision optical engineering. Our multidisciplinary team of mechanical, optical, and electrical engineers possesses a deep understanding of the complexities involved in light pipe design, from material science to optical geometry and viewing angle optimization.

We are committed to delivering solutions that not only meet your luminosity requirements but also integrate flawlessly with sensitive components, providing robust and reliable performance. Our custom light pipes offer:

● Design Flexibility and Control: Tailored solutions that adjust length, angle, and spacing for exact indication and uniform light.

● Reduced Production Costs: Streamlined designs that simplify your Bill of Materials (BOM) and reduce overall manufacturing expenses.

● Minimized Light Loss: Optimized designs that virtually eliminate light losses, ensuring maximum efficiency.

● Uniform Illumination: Consistent, high-quality light output that enhances both operation and aesthetics.

● Accelerated Time-to-Market: Our efficient design, simulation, and prototyping process cuts development times, getting your product to market faster.