Application Characteristics

Solar panels can be a great source of renewable energy. However, they must be monitored with great care. In large-scale solar panel installations, if left unregulated, an influx of too much solar energy can cause problems ranging from device destruction to fire hazards. Therefore, proper status indication is crucial for the safe operation of solar panel installations.

The same bright light that charges these panels can make it difficult to read the status indicators on the control panel. Especially when the design isn’t optimized for the task at hand.

Our client came to us with a unique design challenge — drastically reducing the amount of light being lost in its current design while improving the panel’s poor daytime visibility.

Application Requirements

Because of the glaring sun and control panel design, light needed to illuminate the side of the indicator rather than the top of it. With the current design, the top of the light pipe was not only wasteful — it caused challenges for technicians in properly assessing the operating status of the panels.

Our team needed to design a solution that would:

- Direct more light from the side of the light pipe

- Work with the pre-existing LED voltage specifications

- Reduce amount of light being lost from the top of the light pipe

- Enhance daytime visibility of device

Solution / Approach

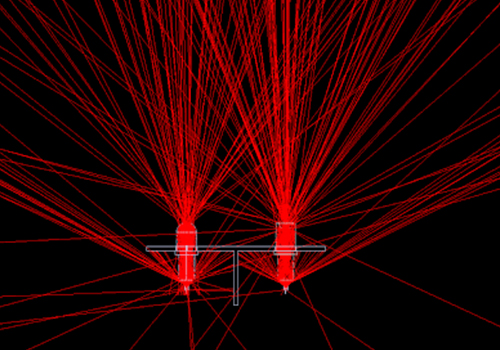

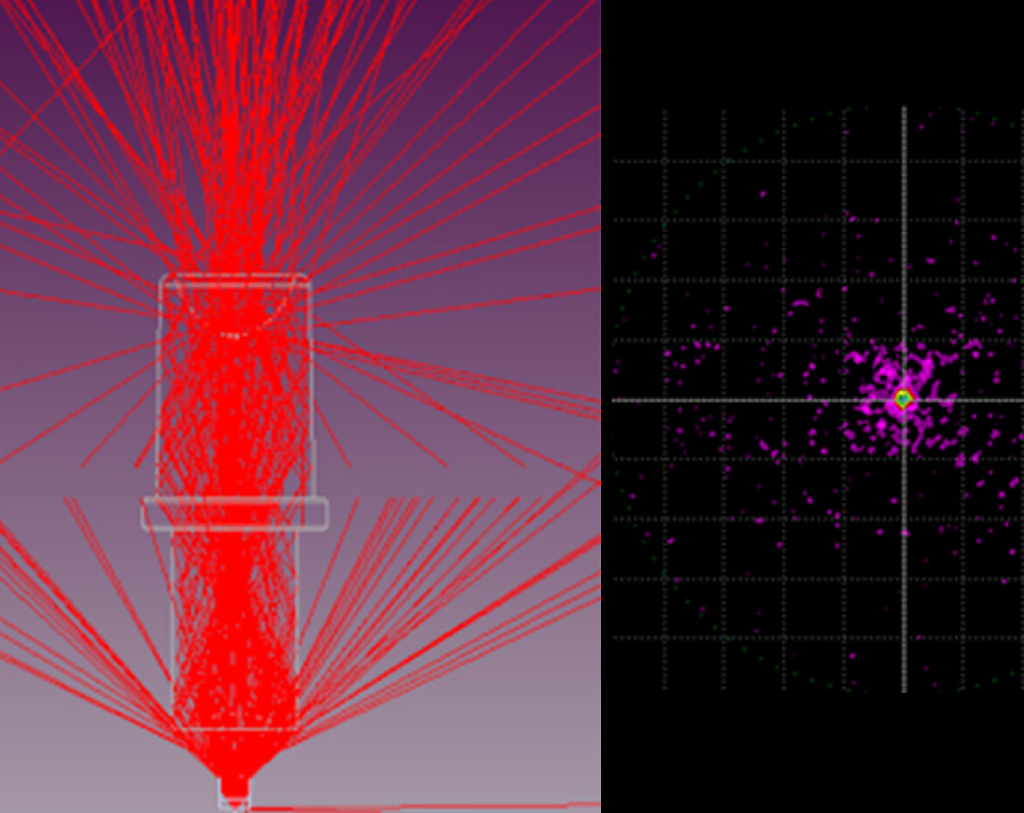

To determine the best possible design, our team ran simulations using advanced light modeling software.

We quickly discovered several inefficiencies with the existing design:

Distance between LED and light pipe

Because of the space between the light pipe and LED, 39% of the light was being lost.

Dome shape of light pipe

When designing light pipes, it’s important to understand total internal reflection (TIR), or the angle at which the light turns back into the light pipe rather than going to the desired exit point. In this case, the dome shape caused most of the light to shine back down into the light pipe. Total Internal Reflection is a wave phenomenon critical to the function and failure of light guiding structures.

These simulations validated our team’s updated light pipe design would meet the customer’s needs. We then used a 3D printer to create samples for testing prior to tooling the light pipe.Through a fast and collaborative approach to light modeling and prototyping, the VCC team ensured we had the ideal solution prior to production.

Results & Benefits

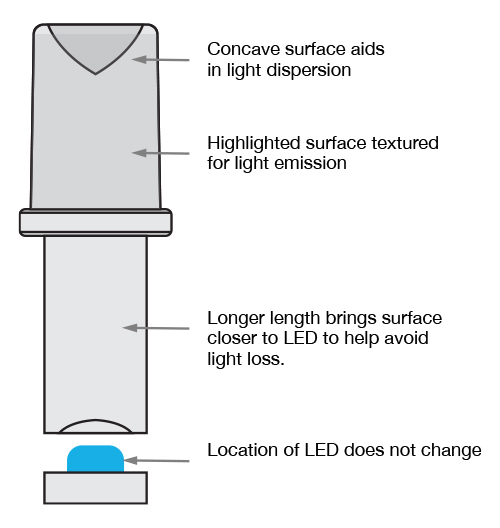

To address these opportunities for light loss, our team created a design that:

- Extended the length of the light pipe by .5” to minimize light loss at the bottom near the LED

- Leveraged a concave lens shape to reflect back more light to the cylindrical surface

- Included a textured pattern to minimize TIR on the surface

- Shift the light output focus from the top of the light pipe to the side view, which increased efficiency on the side surface from 2.00% to 25.88%!

- Provided a 360-degree viewing angle for maximum visibility

- Enabled more energy efficient and long-lasting operation of the product, taking overall efficiency from 30% to 46.02%.

Custom solar lights, engineered specifically as light pipes for outdoor solar panel control modules, are designed to solve the critical problem of poor visibility under intense solar glare by mitigating massive light loss.

Value-Added Services

Using the latest in light modeling technology, our team quickly designed, tested and produced a light pipe that drastically optimized performance and reduced light loss.

And we’d like to solve a unique design challenge for you, too. Our team can customize our off-the-shelf products or design something completely new to meet your mechanical, electrical and optical needs.

Increased Light Pipe Efficiency:

Overall light pipe efficiency comparison:

By changing the surface and shape of the lens with a concave design, we were able to help reflect light back into the surface instead of losing it due to total internal reflection TIR.

Case Study Media