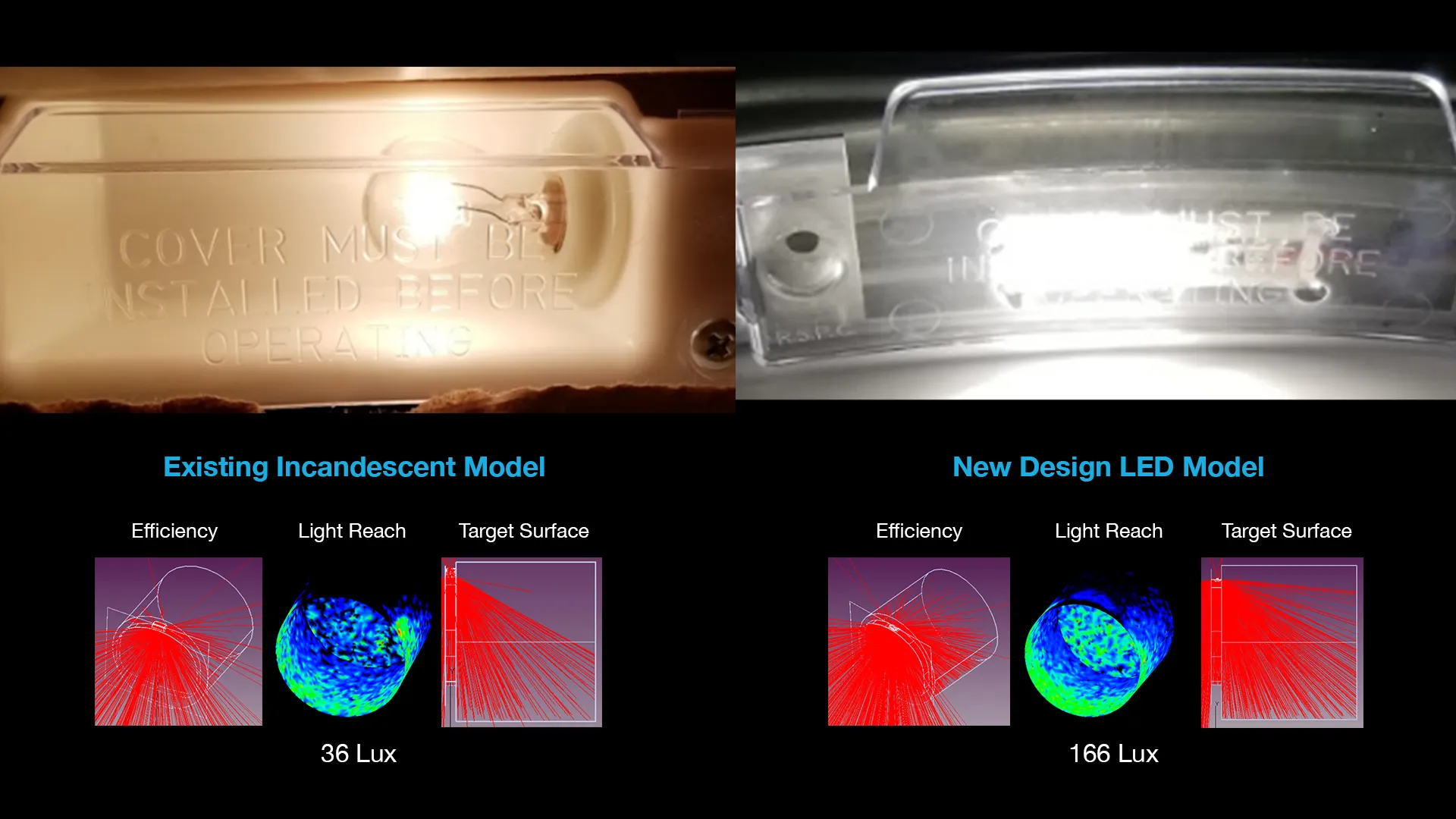

To deliver the ideal LED retrofit, we created a new assembly complete with a heat sink and custom lens while dramatically increasing operating efficiency.

Result & Benefits

While the client came to us for efficient LED technology, we delivered so much more:

- Custom solution that can be used to retrofit several dryer models in the ALS portfolio

- Optimized design for peak performance in high-heat environments

- Reliable operation for 100,000 hours with an LED product rated UL 94 5VA flammability rating (100x the life of the old incandescent bulb that commonly needed to be replaced!)

- Streamlined supply chain, with VCC providing services that would typically be outsourced and slow down production

- Reduced supply chain risk through nearshore manufacturing

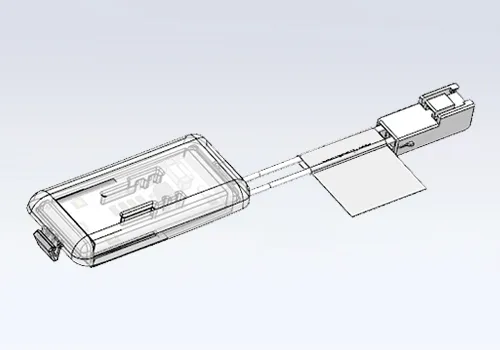

- Exponential installation efficiency and decreased assembly takt time thanks to the snap-in design and elimination of LED wrapper in packaging

- Improved customer satisfaction — buyers love the new, sleeker aesthetics of the LED lights

- Increased efficiency, durability, brightness and color rendering with LEDs that won’t burn out

Application Characteristics

Makers of industrial white goods and commercial laundry products that have been around for over 100 years find themselves with several models that don’t need an entire redesign. But that doesn’t mean there aren’t opportunities to achieve savings in production. And upgrading from incandescent bulbs to advanced LEDs can lead to many benefits beyond reducing costs.

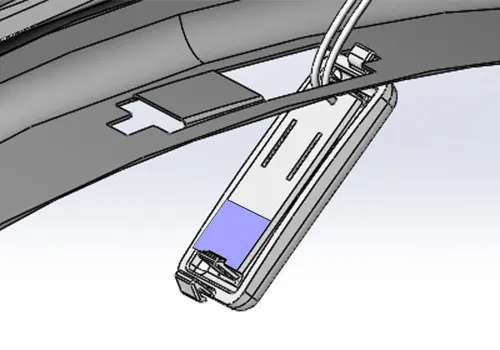

For Alliance Laundry System (ALS), the world’s largest commercial laundry manufacturer, this was the case for multiple retail dryer models. The global laundry equipment powerhouse wanted to upgrade its dryer cylinder light to a modern, sleek LED.

When the OEM couldn’t get the upgrades needed from an existing vendor, a distributor recommended VCC for the job.

Application Requirements

The client’s requirements for the LED retrofit project included:

- Compatibility with existing dryer footprint

- Advanced LED technology in 120VAC and 240VAC options

- Extensive testing and quality standards

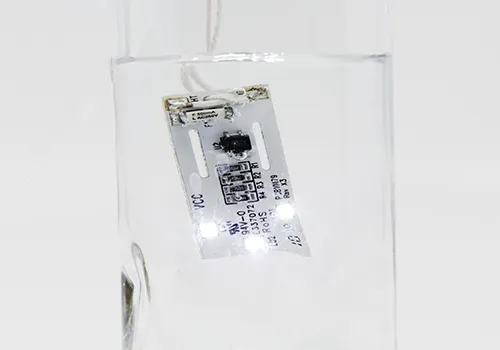

- Waterproof design to accommodate wet clothes

- Safe, reliable performance in a high-heat environment – UL 94 5VA flame rating

- Quick, easy installation

Solution / Approach

ALS is a diverse manufacturer building several hundred different dryer models for a global market. When ALS approached VCC to upgrade all dryers that use a cylinder light, replacing incandescents with energy-saving LED technology, the client wanted two, uniform light assemblies to be used in all market dryers (electronic and non-electronic models).

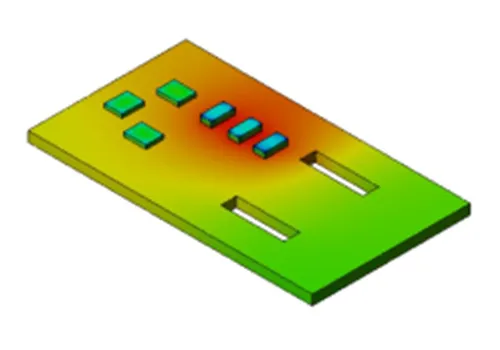

Because of the design footprint, a heat sink was needed to maintain the life of the LED during the high-heat operation of the dryer. We quickly developed a design that included a mechanical barrier between the metal core PCB and the edge of the dryer drum, utilizing thermal tape to accommodate the high heat.

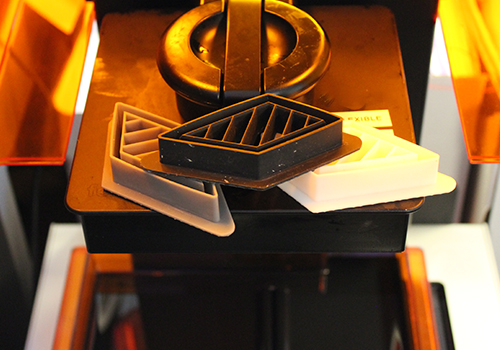

Our team then used a 3D printer to create a prototype for testing and optimization

Value-Added Services

VCC is proud of our partnership with ALS, which provides value-added services that go beyond our advanced LED technology.

Using a holistic approach, our team helped the client reduce the number of vendors and touchpoints associated with installing wires and connections.

Combined with our innovative packaging solution, we helped this industrial goods giant gain a competitive edge by offering a sleek, modern, and reliable product consumers love.

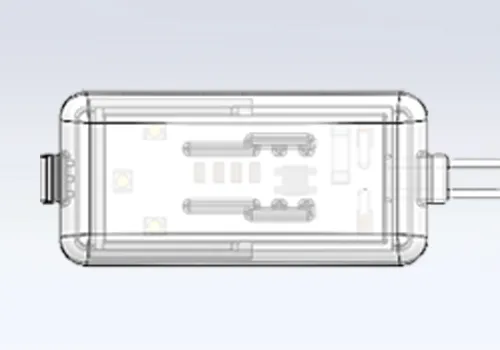

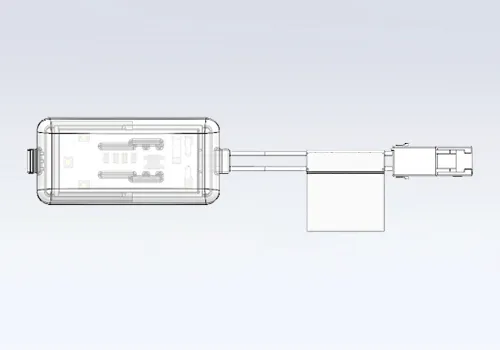

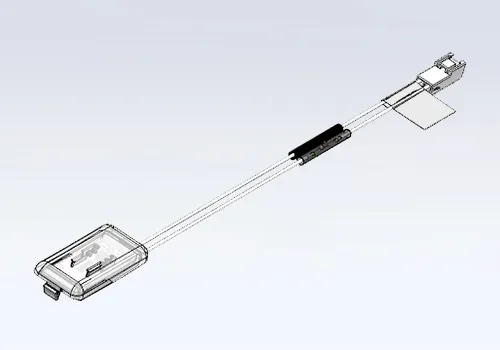

The innovative solution was made up of:

- Long-lasting LEDs compatible with 120VAC and 240VAC

- Custom lens to accommodate heat sink

- PCA assembly that was isolated from the drum metal to pass agency-required hipot and surge testing

- Wired leads for the power source

- Snap-in hooks for easy installation without tools

In addition to providing a custom LED board and light engine, VCC was the one-stop-shop for:

- Cable assembly

- Light engine design

- Custom plastic manufacturing

- Quality inspections

- Testing

- Agency certification (critical for implementation)

ALS got much more than advanced LEDs to replace the antiquated incandescent dryer light — like a fully wired and ready to go LED module. Installation times were reduced when we revamped the packaging of the LED modules. By eliminating the need for a plastic wrapper around the LEDs and using a slotted packing tray to protect the lenses, we sped up installation times from 39 seconds to 13!

We couldn’t be happier with the end result. VCC’s solution provided us with the cost savings we wanted by helping us to decrease installation time and helped us improve the aesthetics of our dryers. It was truly a win-win for us.

Model: 120VAC

Operating Efficiency

2034%

Industry Average

Power Usage Compared to Incandescent:

Operating Efficiency

1081%