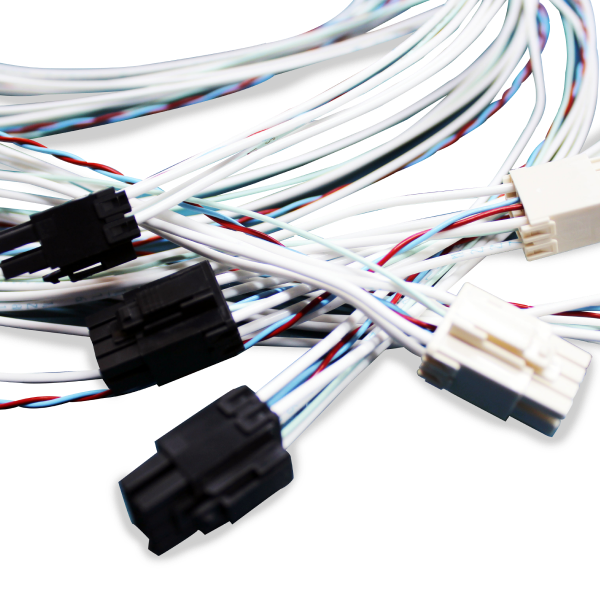

Cable Assembly

VCC’s cable assembly and wire harnessing services simplify production, empowering customers to get to market faster.

By offering a holistic, single-vendor solution, VCC significantly simplifies complex production processes and empowers businesses to achieve faster market entry.

Why Choose VCC for Cable Assembly?

Adding Customization & Value

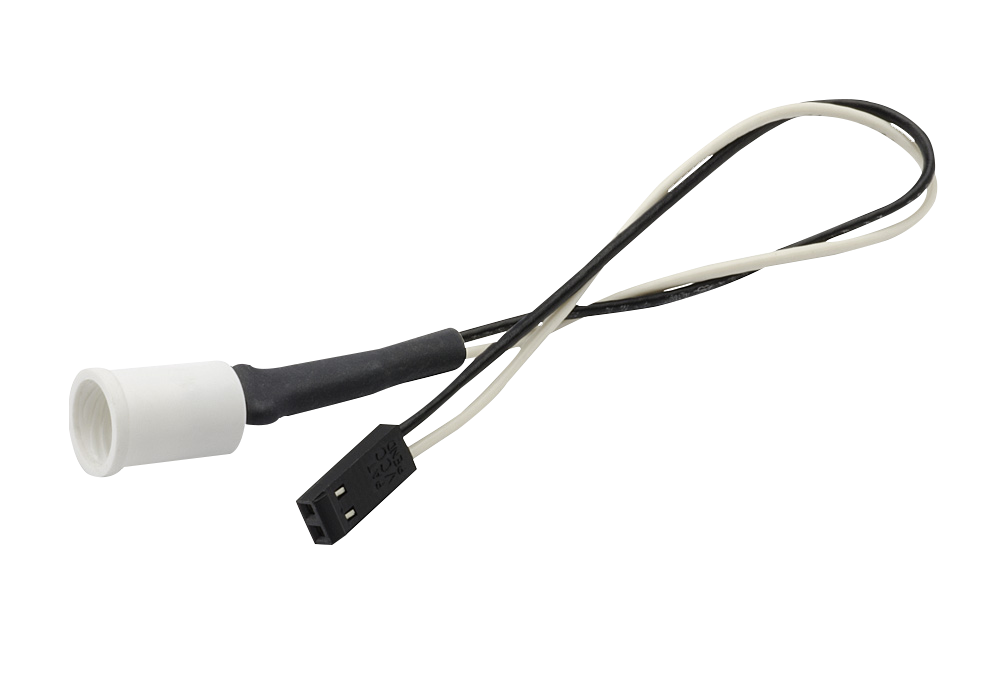

At VCC, we know every project, requirement, and customer is unique, so we offer the expertise of our engineering services from design and prototyping to volume production.

No matter the project, we enhance production efficiencies by providing these value-added services:

- Cable crimping: Providing secure and reliable electrical connections.

- Cutting: Precise preparation of wires and cables.

- Soldering: Creating durable and conductive electrical bonds.

- Harnessing: Organizing and protecting wire bundles.

- Testing: Verifying performance and compliance with specifications.

- Final product assembly: Streamlining the customer's integration process.

VCC’s Cable Assembly & Wire Harnessing Benefits

Maintain Process Control

Reduce Manufacturing Costs

Streamline Your Supply Chain

Easily Roll Out Upgrades or Modifications

Cable Assembly Process

We take pride in delivering custom assemblies that exceed our customers' rigorous standards as well as our own. VCC’s unwavering commitment to extensive testing and rigorous quality is why our customers trust us time and time again.

Our proven process allows us to produce reliable assemblies and harnesses with precision.

Step 1: Design Review

Step 2: First Articles

Step 3: Testing and Validation

Step 4: Production

Flexibility for Upgrades and Modifications

VCC's design philosophy incorporates flexibility that allows manufacturers to readily upgrade or change the design of existing products. This capability is important for product lifecycle management, as it allows customers to extend the life of their products and significantly reduce the costs typically associated with design changes. This capability allows customers to adapt their products to evolving market demands, technological advancements, or regulatory changes without requiring a complete redesign or costly retooling.

Mitigating Supply Chain Risks and Ensuring Scalability

CC's manufacturing capabilities provide precise PCBA and cable assembly services, mitigating supply chain risks and supporting scalability across diverse industries. This means VCC can guarantee a consistent supply of components and support high-volume production, helping customers grow their businesses with assurance to meet demand. They provide continuous delivery of high-quality cable assemblies or wire harnesses to help customers stay competitive.

Our experienced team is committed to helping clients develop complete solutions in rapid development times, offering flexibility and agile response.

With extensive development skills and expert control over various technologies and integrated processes, such as lean engineering, we are prepared to effectively solve any HMI-related challenge.

It all starts with a review of each customer’s requirements. Contact our experts to discuss contract manufacturing or custom services for your project.