Customized Solutions

VCC custom product development programs include LED light pipes, special function panel indication, indicator assemblies, LED lenses and more. VCC excels at working closely with OEM Partners throughout the product realization process to design and manufacture the perfect custom LED solution for their applications. With this focused approach, VCC adds value to any product offering, from the simplest indicators to the most complex light delivery requirement.

Product Design

VCC possesses comprehensive expertise in mechanical, electrical, and optical design. Placing considerable value on aesthetics and utilizing the best CAD and light modeling software available, we collaborate with you to create detailed designs, drawings, and schematics.

Production & Supply Chain

To VCC, the manufacture of high quality products with short lead-times is critical to delivering best-in-class customer service. Thanks to our international production sites and our global fulfillment centers, we offer you efficient and sustainable logistics so you have product on-time.

Prototyping

VCC utilizes the latest in high resolution stereolithography (SLA) equipment and a broad variety of resins to quickly produce high-tolerance and accurately detailed prototypes.

Value-added

VCC utilizes the latest in high resolution stereolithography (SLA) equipment and a broad variety of resins to quickly produce high-tolerance and accurately detailed prototypes.

Value-added Services

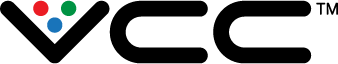

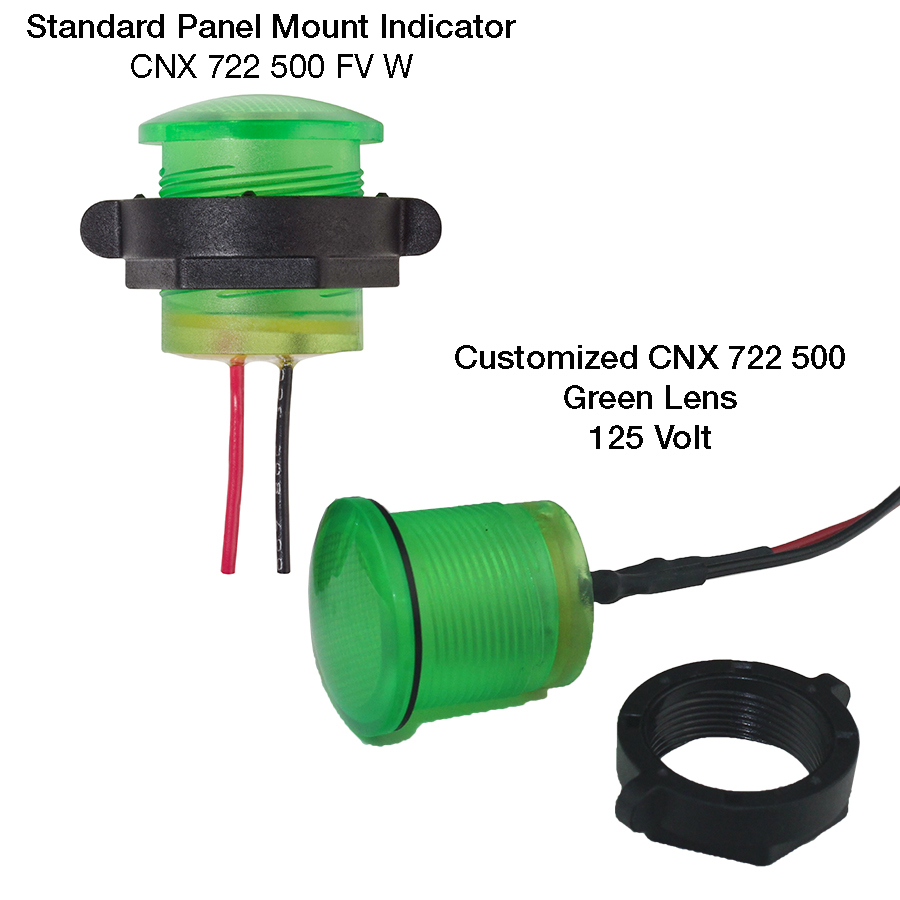

VCC’s value-added services team can modify our standard illuminated components or design a fully custom solution in accordance with our customers’ mechanical, electrical, and optical needs.

For customizations big or small, we possess comprehensive expertise in design, prototyping, tooling, manufacturing, and assembly.

-

Light Modeling design services

-

Customized cable harnesses

-

Mechanical, electrical and optical changes

-

Conformance with UL, cUL, CE, RoHS, REACH, and WEEE regulatory requirements

-

NEMA and IP Rating performance

Examples

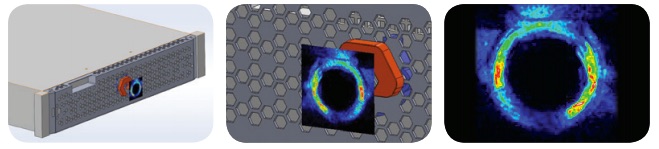

Industry: Computer

Company Profile

A fast growing Silicon Valley-based enterprise data flash storage company

Business Challenge

Design a light pipe assembly and USB-powered LED module to illuminate the Company badge on the front of its product

Solution

VCC utilized advanced light modeling and human vision simulation to simulate and analyze the photometric and illumination properties of the proposed design. We then optimized for performance, efficiency, and appearance.

Due to limited power availability, VCC developed an LED module that took advantage of a nearby USB port for its power.

Cost

- Mechanical, electrical, and optical design: $12,000

- Multiple functional prototypes: $500

- Production tooling: $12,000

- Lightpipe assembly + LED module production: $18 per set

Industry: Mil/Aero

Company Profile

Global designer and manufacturer of aviation Ground Support Equipment (GSE)

Business Challenge

Company was designing a compact, self- contained, trailer-mounted, electric motor driven Liquid Coolant Supply (LCS) cart designed to supply chilled coolant to an aircraft liquid coolant loop while the aircraft is on the flight deck. A large format daylight visible indicator was needed, that also had to be shielded from electromagnetic interference (EMI).

Solution

VCC designed a customized indicator that delivered the EMI shielding and daylight visibility that were required by the Company. In order to maximize the LED intensity and viewing angles, VCC incorporated its existing HMS 462 lens into the product. This patented Fresnel lens design is resistant to dust, water, oil, and high vibration environments. By incorporating this existing product, VCC was able to eliminate an tooling costs that would have been otherwise required.

Cost

- Mechanical, electrical, and optical design: $12,000

- Multiple functional prototypes: $1,000

- Production tooling: None

- Panel mount indicator cost: $23

Are you ready for next level illuminated components?

Start a conversation with one of sales engineers today.Panel Mount Indicator

LED Watertight PMI Build Your Own Indicator Neon Incandescent More

Circuit Board Indicators

LEDs

Latest Products

Check all the Latest Products

Custom Wire Harness

Custom Solutions

Custom Design Capabilities

Technical Resources

Product VideosBrochuresCustom SolutionsNewsCase StudiesFAQsGlossaryVideo Webinar

Purchasing

Product

Videos

Learn more about our products

The Latest

Contact

Contact Us

Call Us 1.800.522.5546