Crisis ColLAB & Coronavirus:

One Year, Many Contributions

It’s still hard to believe and accept that it’s been a year since the COVID 19 pandemic changed our lives forever. As painful as the last 12 months have been, it’s important to reflect on some of the great strides we’ve made by working together to end this virus and get the world back on track.

On March 30, 2020, we launched Crisis ColLAB, VCC’s effort to contribute to the cause in the best and most valuable ways possible — by donating our design services for medical and PPE companies supplying the frontlines, including:

Design software for creating and testing solutions

3D printing know-how and machinery

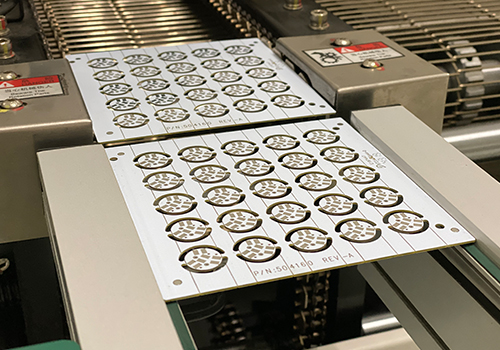

Proven performance in designing and prototyping PCB assemblies, light engines, and other electronic components

Since its inception, Crisis ColLAB has been a multi-team, multi-pronged initiative. Here’s a recap of our efforts in this fight:

Procurement & donation of existing components

We collaborated with internal teams and our global distributor network to:

- Donate 2,000 components used in defibrillators to a distributor for use in Italy

- Prioritize medical and pandemic-related projects over all others for our design and engineering teams

- Speed up production for 65,000+ components to be used in ventilators and respirators

- Ensure all of our designs could be produced with in-stock components to avoid delays

Donation of design services for mission-critical medical device

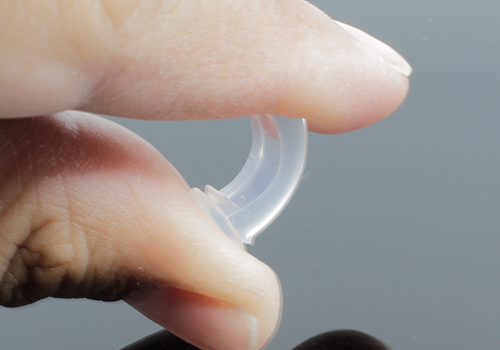

VCC’s primary focus for Crisis ColLAB was to put our design and light pipe expertise to work in combating the virus. One vaccine delivery device manufacturer enlisted our free design services to optimize an existing product — and fast.

It definitely seemed like the odds were stacked against us, with challenges including:

Team Safety

Our designers and engineers needed to work remotely for social distancing and safety protocols, alternating shifts when work in our Design LAB was required.

Speed

Traceability

Logistics

The issues listed above were only part of our mission — we also had to work within the design constraints of an existing device.

While the original scope was to optimize the design of the three status indicators, the scope evolved once the client realized VCC’s capabilities.

Design Process

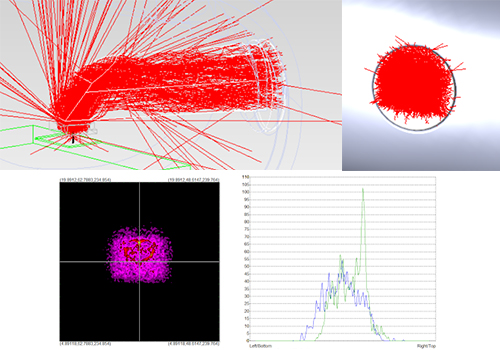

- Optimized light pipe design for three separate indicators

- Produced several one-time use tools to show proof of concept

- Conducted multiple light simulations

- Printed 3D prototypes printed in-house

- Made subsequent aesthetic updates during production

Results

- Reduced light loss and increased efficacy by a total of 1,561%

- Enhanced accuracy and uniformity by adding a textured lens to each light pipe

- On-time delivery, even through late-stage design revisions thanks to air freighting due to global shipping backlogs

Increased Light Pipe Efficiency

Overall light pipe efficiency

VCC Design

- 127% Efficiency 98%

Previous Design

- 30.83% Efficiency 20%

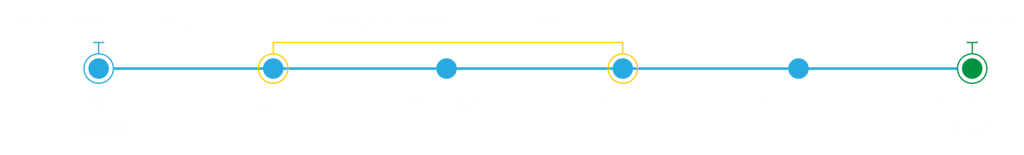

Our client enlisted our help in July of 2020, with prototypes delivered and revised throughout August and October. Full delivery of the first batch came in December, with the device on target for clinical trials.

We donated the design services through multiple revisions and scope changes, while the client covered late-round prototypes, tooling, and production costs.

Since then, the innovative device has been used in multiple clinical trials with data on track for review in early 2021.

“I couldn’t be prouder of our team for navigating all of the challenges and hurdles required to perfect this device and get it into production as quickly as possible, It was a true collaboration and I’m confident this device will lead to great strides in beating COVID 19.”

Thomas Macon

VP of Sales, VCC

Shared Knowledge with Manufacturers Worldwide

To help those companies whose production came to a screeching halt due to shutdowns in China and supply chain disruptions just about everywhere, our CEO, Andy Zanelli, participated in interviews and panel discussions along with other experts:

While we are still battling coronavirus, the end is in sight. We’re proud of the contributions we made to helping frontline workers, clinical researchers, vaccine producers, and manufacturers throughout this crisis.

Have your own mission-critical design project?

Learn more about VCC’s custom capabilities Learn MorePanel Mount Indicator

LED Watertight PMI Build Your Own Indicator Neon Incandescent More

Circuit Board Indicators

LEDs

Latest Products

Check all the Latest Products

Custom Wire Harness

Custom Solutions

Custom Design Capabilities

Technical Resources

Product VideosBrochuresCustom SolutionsNewsCase StudiesFAQsGlossaryVideo Webinar

Purchasing

Product

Videos

Learn more about our products

The Latest

Contact

Contact Us

Call Us 1.800.522.5546